Editors’ Picks

Found in Robotics News & Content, with a score of 7.90

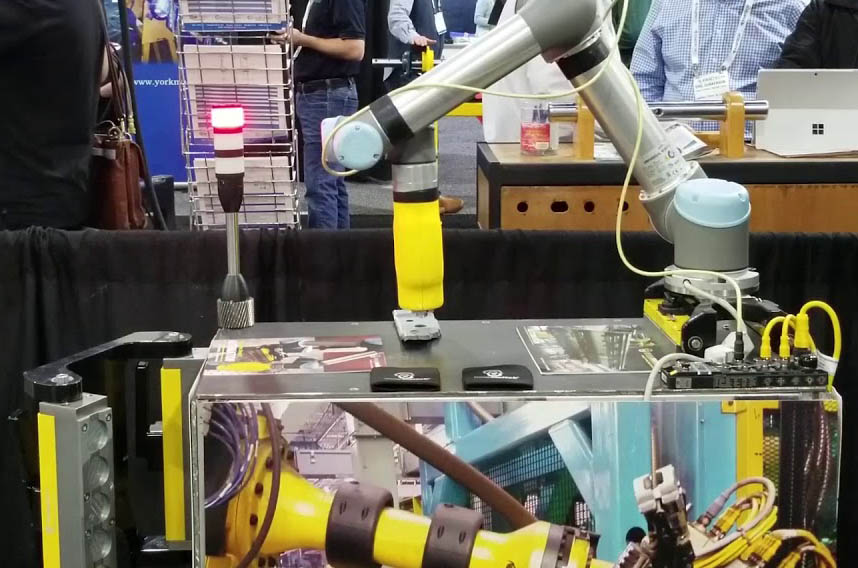

…specifically screwdriving, with Tool House; machine tending with Ellison; welding with MRO; and pick and place and palletizing with Tool House and RG. The company also showed 3D scanning for automotive inspection with Korean partner Hexagon Metrology. In a grinding and polishing demo, Doosan showed how a user could tilt a smartphone to control the angle of a robot. Designing a future with more robots Beyond its Automate exhibits, Doosan Robotics is working on more software-driven capabilities. It works with the Robot Operating System (ROS). The company said it is building on its suite with a platform and integrated development…

Found in Robotics News & Content, with a score of 7.90

…and leads its business development and application engineering teams. He has over a decade of experience in under-the-hood robotic welding and applications experience, which has given him both the passion and the know-how to help manufacturers identify how to improve weld processes with automation. Moderator: Eugene Demaitre Editorial director Robotics 24/7, Peerless Media LLC Demaitre is editorial director of Robotics 24/7. Prior to joining Peerless Media, he was a senior editor at other robotics publications. Demaitre has decades of experience in business-to-business, online technology coverage and has participated in numerous robotics-related webinars, podcasts, and conferences worldwide.

Found in Robotics News & Content, with a score of 7.77

…The use of industrial robots for tasks such as welding and sheet handling in heavy industries has also proved the efficiency of the robotic systems in terms reduction in cycle time and raw material wastage. With the growth in the implementation of robotic solutions in the heavy industries sector, end-users can attain the operational flexibility required for addressing different product requirements. Robots are ideal for multitasking and can handle repetitive tasks efficiently. They are swift and can be deployed in accident-prone areas in production lines. During 2015, the material handling robots segment accounted for nearly 47% of the global industrial…

Found in Robotics News & Content, with a score of 7.63

…mm in thickness, according to the company. In resistance spot-welding applications, E-Series units provide single-sided gripping technology, eliminating the need for clamps, said Festo. With clamps removed, the spot weld gun is provided simpler access to the product. With a rapid on/off actuation time of 250 milliseconds, the E-Series can lower cycle time in comparison with clamps, said Festo. Magswitch said its E-Series grippers can be used in many other applications, including automotive assembly, white goods manufacturing, heavy industrial manufacturing, electronic assembly, bin picking, measuring, checking, ergonomic lift-assist, and collaborative cells. Novel uses for magnetic gripping Bond gave two examples…

Found in Robotics News & Content, with a score of 7.60

…of trade tools and materials, including hand-held power tools, welding and cutting equipment, inspection and test equipment, parts and components, hazardous materials, and retail inventory goods. Sarcos recently put the advanced teleoperation control system, including the SenSuit motion-capture controller, and Guardian XT robotic system, to work in a live tree-trimming demonstration at its headquarters in Salt Lake City, Utah. It said the product will be commercially available by the end of 2022. About Sarcos Robotics Sarcos said its technology is based on more than 30 years of research and development into mobile robotic systems to augment human performance. Its systems…

Found in Robotics News & Content, with a score of 7.46

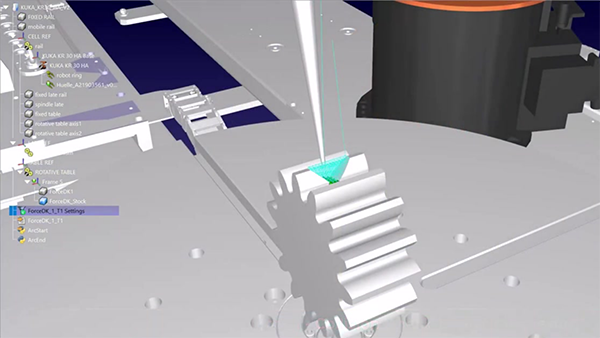

…mm takes time to carefully CNC.” Improve your laser welding initiatives with RoboDK industrial simulator RoboDK eliminates the need for shop floor programming and optimizes robot paths to avoid singularities, axis limits, and collisions. Due to its innovative design, coding experience isn’t necessary. By combining RoboDK with another system, such as the ESPRIT, Hexagon’s “Hybrid” CAM, companies can develop sustainable production processes. It reduces energy consumption and waste generated from their operations. Using RoboDK’s simulation and offline programming tools helps companies reduce production costs and downtime. Moreover, it minimizes hazardous materials produced in production cycles. These advantages make RoboDK an…

Found in Robotics News & Content, with a score of 7.45

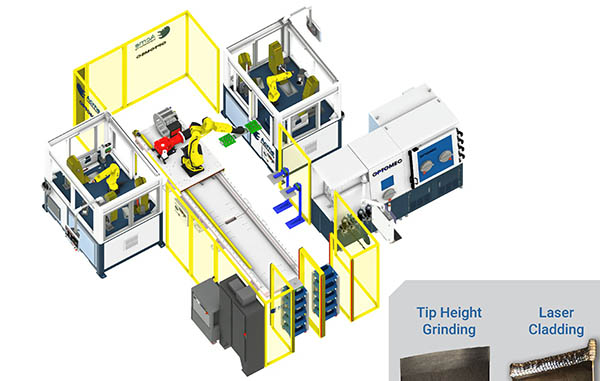

…when compared to traditional CNC machines and manual TIG welding.” The workcell uses commercially available technologies that have been certified by civil aviation authorities around the world, said the companies. The entry-level workcell consists of three stations that enable robotic blade tip grinding, 3D additive laser cladding, and robotic post-clad finishing. The cell also includes an automated pallet load/unload station, a pallet-flipping station, and a robotic material handling system. Each machine in the workcell is capable of automatically adjusting tool paths to accommodate blade-to-blade variations resulting from normal wear and distortion during service. Optomec said its CS-250 five-axis laser cladding…

Found in Robotics News & Content, with a score of 7.38

…packaging, quality testing, material handling, machine tending, assembly and welding, currently represent 3% of global robot sales, according to the International Federation of Robotics, but the share is expected to rise to 34% of a $25 billion market by 2025. “This growth will most definitely depend on cobots being used in more applications,” Iversen added. “Their small footprint and ability to work safely alongside humans make them ideal for small and medium-sized manufacturers who need to compete globally. Cobots are also increasingly integrated into very large manufacturers such as automotive plants, where they are taking over processes that can’t be…

Found in Robotics News & Content, with a score of 7.37

…“This involves cognitive industrial robots for applications such as welding, warehousing, gluing, sanding, and assembly,” explained Reger. “However, this volume only describes the minimum delivery volume over the next five years. The actual demand of our customers is much higher, but currently still limited by our production capacities.” “For a better classification of the demand as a whole—the order volume mentioned results from just one-time 14 contracts,” he noted. “We currently have around 100 more contracts under negotiation. That is why the new capital is so important, because we need to expand our production capacities very quickly.” NEURA is developing…

Found in Robotics News & Content, with a score of 7.37

…handling, palletizing, machining, testing, bonding, screw locking, polishing, and welding. JAKA stated that its collaborative robots have increased production capacity and efficiency, reduced heavy physical labor for human workers, increased worker safety, and mitigated high staff turnover. The vendor claimed that more than 10,000 of its cobots are in operation worldwide, including in the production lines of well-known brands in the automotive, electronics, semiconductor, and other industries. It has established technology centers in Japan and Germany and is working with more than 300 automation companies to provide localized services. Earlier this year, the company launched the new JAKA Pro series…

Found in Robotics News & Content, with a score of 7.33

…motion control, artificial intelligence (AI) and related automation technologies. Welding, assembly and machine tending robots, mobile robots and human-robot collaborative technologies with intuitive user interfaces and software advances, machine learning and advanced computer vision technologies are just a few of the solutions that will be on display. Many companies will be introducing new technologies never before seen in North America. More than 120 Automate conference sessions explore how automation secures a company’s success in a technologically fast-paced world where AI, IIoT, smart manufacturing, cobots, machine vision and other innovations are rapidly shifting the dynamic of today’s manufacturing. Industry professionals can…

Found in Robotics News & Content, with a score of 7.27

…automated bin picking application for machine tending and TIG welding applications to drive productivity and help the company compete nationally and globally. “The only way that made sense for us to put a robot on a machine-tending application was to be able to do randomized bin picking,” explained Zach Northway, co-owner and lead project engineer at Flywheel Supply. “The cycle times on the machine are so short that if an operator has to stand there and line parts up in an organized fashion for a robot to pick them in a traditional sense, it would defeat the entire purpose of…