Editors’ Picks

Found in Robotics News & Content, with a score of 24.17

Additive manufacturing is widely considered an intrinsic part of the factory of the future. The technology has developed alongside progress in robotics, with interest in manufacturing innovation leading to new methods of production. Metaphorically, it is the bloom of a new machine. Additive manufacturing, or AM, represents only 1% of manufacturing so far, according to research conducted by SmarTech Publishing. To grow, the technology must overcome several challenges. They include the complexity of multiple fabrication steps, the high cost of scaling production, and a shortage of a skilled workforce to help control quality in the absence of industry standards. Robots…

Found in Robotics News & Content, with a score of 24.12

Take a closer look at how Stratasys Additive Manufacturing is helping a company entrenched in Powersports vehicles drive innovation forward. Polaris is most commonly known for developing snowmobiles and off-road vehicles. With all the hands-on assembly work that the company does in the plant, they've begun to use 3D printing to change the way that they make tooling. Much of what the company does works around different styles of tooling. Polaris says the biggest benefit of partnering with Stratasys and their technology is the ability to iterate on new tooling designs.

Found in Robotics News & Content, with a score of 24.09

…wield advanced technologies like generative design (GD) software and additive manufacturing (AM) to deliver TIGER (Transforming Intelligent Ground Excursion Robot), a concept vehicle announced earlier this month. As a follow-on to Elevate, its first UMV concept with moveable legs, the TIGER X-1 concept vehicle is based on a modular platform architecture that includes a sophisticated leg and wheel locomotion system, 360-degree directional controls, and a range of sensors for remote observation. The UMV can transform from four-wheel drive to four-leg walking and operate without a crew to perform different missions such as delivery in urban settings, transport of critical supplies…

Found in Robotics News & Content, with a score of 24.07

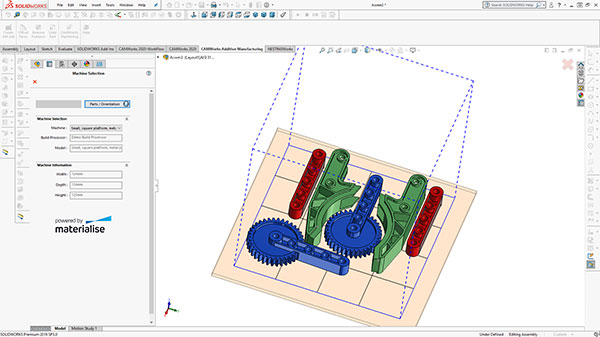

…enhancements to assist machine shops in advancing their smart manufacturing practices. CAMWorks Version 2020 provides support for 3D printing of SolidWorks Assemblies, the CAMWorks ShopFloor product, intelligent probing functionality and automatic tab machining. With Version 2020, the CAMWorks Additive Manufacturing module, powered by Materialise, has extended 3D printing functionality to SolidWorks Assemblies. Multiple parts from the same assembly or different assemblies can be nested onto the build platform, which saves time and increases efficiency, and CAMWorks Additive Manufacturing automatically generates the build supports. CAMWorks Additive Manufacturing is fully integrated into SOLIDWORKS and allows 3D models to be printed directly from…

Found in Robotics News & Content, with a score of 23.96

…3D printer. 3D Systems and the National Center for Manufacturing Sciences (NCMS) were awarded funding to create this revolutionary printer and will partner with ARL and the Advanced Manufacturing, Materials, and Processes (AMMP) Program to advance the leadership and innovation of the world’s strongest military. According to the U.S. Army Additive Manufacturing Implementation Plan, the Army has been using additive manufacturing (AM) for two decades to refurbish worn parts and create custom tools. Once developed, the Army will leverage its manufacturing experience by placing the new large-scale systems in its depots and labs. Subsequently, 3D Systems and its partners plan…

Found in Robotics News & Content, with a score of 23.95

…providers of the accelerated geometry kernel used to build additive manufacturing (AM) hardware and software solutions, announce a long-term licensing agreement with HP to help power their next-generation cloud and edge-based digital manufacturing solutions, the companies report. The collaboration is designed to bring performance, efficiency, automation, and extensibility to the company's growing portfolio of digital manufacturing products, the companies add. This agreement demonstrates HP's commitment to industry innovation in three key areas; quality, performance and automation. “From the very beginning, HP recognized the potential of Dyndrite's kernel technology. As the first member of the Dyndrite Development Council, we quickly identified…

Found in Robotics News & Content, with a score of 23.92

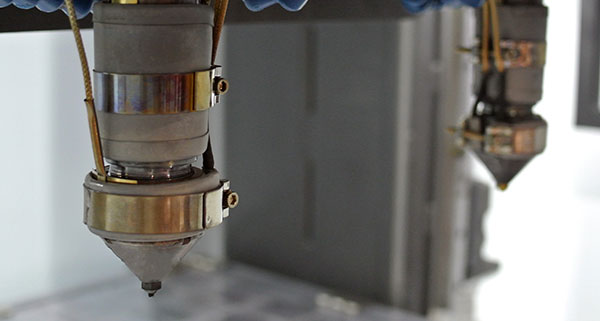

…development and implementation of pellet extrusion technology in the additive manufacturing industry,” says Clay Guillory, Titan Robotics CEO, via a press release. “Our Atlas-H product launch aligns with Titan’s mission to develop innovative solutions and technologies to bring additive manufacturing into industrial production.It strengthens Titan’s reputation as one of the most innovative companies in the industry.” Titan has been a pioneer in the development and implementation of pellet extrusion technology in the additive manufacturing industry. Image courtesy of Titan Robotics. Titan Robotics says pellet extrusion 3D printing on the Atlas with a heated enclosure significantly increases the number of materials…

Found in Robotics News & Content, with a score of 23.84

…says is critical to protect electrostatic-sensitive devices in electronics manufacturing, oil and gas and aerospace industries. Essentium says the HSE 3D printer is up to 10x faster and 5x more accurate than competitive offerings. The 3D printing platform offers print speeds greater than 500mm a second by using a non-slip, high torque extruder system and all linear motor. Supplementing the capabilities of the hardware, Essentium says it has tuned the materials accordingly to process at speed while being strong enough to withstand impact loading, fatigue or cyclic loading and protect electrostatic-sensitive devices. The company says early access program customers are…

Found in Robotics News & Content, with a score of 23.84

…make quick physical prototypes to a solution for short-run manufacturing, bespoke offerings and complex parts that just can’t be economically made via traditional methods. “By 2030, the number of production-ready additive manufacturing platforms that ship each year will increase more than tenfold (more than US$325 billion in hardware and related systems revenue),” according to ABI Research’s white paper: The Industrial Revolution, the Top Trends and Takeaways from Hannover Messe 2019. “These systems will produce more than US$360 billion worth of parts and end products each year (up from US$6.8 billion today) and nearly US$2 trillion in sum by the end…

Found in Robotics News & Content, with a score of 23.84

…Team created this design guideline for 3D printing and additive manufacturing technologies—get answers for commonly asked questions specific to designing for Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), Stereolithography (SLA), and PolyJet (PJ). The easy-to-use chart includes wall thickness, hole diameter, clearance for assemblies, escape holes, minimum detail, pin diameter, Z & XY accuracy, and standard layer thickness. FATHOM’s Application & Engineering Team is always adding to this chart, so check back often for any updates. Fused deposition modeling Fused Deposition Modeling (FDM) is ideal when you need to build concept models, functional prototypes, and…

Found in Robotics News & Content, with a score of 23.83

In June 2019, long-time additive manufacturing industry vet Ron Hollis took over as president and CEO of MFG and set about rebuilding the manufacturing marketplace. To DE readers, he may be best known as the founder of custom parts services company Quickparts.com in 1999. He led the firm through a period of rapid growth until 3D Systems acquired it in 2011. He spoke to Digital Engineering about the changes that are happening at MFG, as well as his thoughts on the present state and future of the additive manufacturing market. Digital Engineering: Can you tell us about the impetus behind…

Found in Robotics News & Content, with a score of 23.81

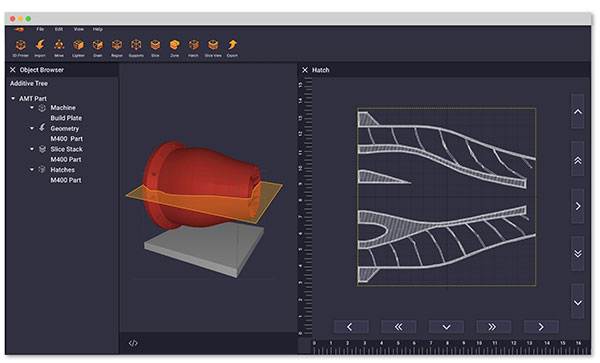

Dyndrite Corporation unveiled its Additive Manufacturing Toolkit (AMT) and accelerated production preparation build processor for 3D printing. The company also announced the “Magic Amnesty Program,” a limited-time offer for premier metal and industrial plastic additive users. Built upon the company’s Accelerated Computation Engine (ACE), a GPU-powered geometry kernel, AMT provides manufacturing-oriented features. Capabilities include native CAD file import for maximum quality of 3D-printed output, as well as an integrated Python application programming interface (API) for customizable scripting of interactive, automated workflows. Dyndrite’s ACE geometry kernel and AMT build processor were designed from the ground up using a “First Principles” approach,…