Editors’ Picks

Found in Robotics News & Content, with a score of 18.03

…state and university programs in the U.S., and global additive manufacturing OEM programs. This is not a comprehensive list and some programs may require additional fees, specific products and materials, prior government compliances or agreements, membership or other requirements. AMUG advises its members to tap into their AM network and participate in programs that are in line with respective organizations' capabilities and resources. If you are part of a regulated (controlled) program in the Americas, Asia, Europe or Oceania region that is not listed here, please email the information to [email protected]. AMUG says it will do its best to add…

Found in Robotics News & Content, with a score of 14.00

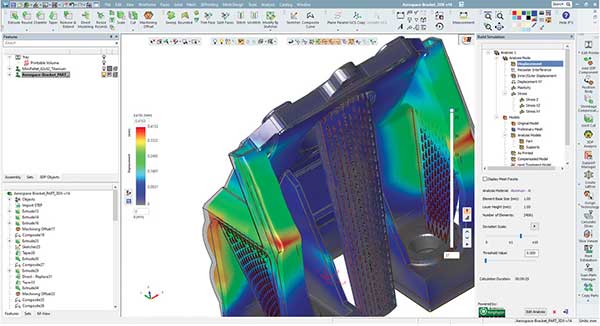

…the limitations of production technologies. However, the advances in additive manufacturing (AM) or 3D printing flipped the situation. Many CAD users found out their software couldn’t digitally model the complex shapes AM hardware is itching to print. Classic parametric modelers were developed to produce geometry suited for machine shops. But AM is capable of so much more. It can produce lattice fills, membrane-like structures and swirling geometry—nicknamed alien topology by some—the kind few will attempt to fabricate using machining. To fill the gap, some AM hardware makers, such as Desktop Metal and 3D Systems, developed their own software. CAD vendors…

Found in Robotics News & Content, with a score of 10.90

Metal additive manufacturing (AM) stands poised to expand its footprint in the manufacturing sector, transitioning from a proven prototyping tool and small-lot fabrication process to mainstream part production. But there’s a catch. Today’s AM technology isn’t predictable and repeatable enough to be cost-effective for companies that want to use AM to mass-produce parts. Currently, engineers must go through an iterative process of trying different printing parameters before they can identify the combination that will enable them to build parts that meet the necessary quality standards. AM Process Simulation Software Buyer’s Checklist When choosing additive manufacturing (AM) process simulation software, cost…

Found in Robotics News & Content, with a score of 43.54

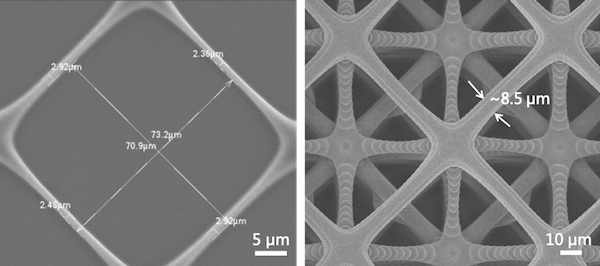

…PT Register Today! One of the new frontiers in Additive Manufacturing (AM) is the production of high-resolution, high-accuracy microstructures for industrial applications. These parts are not only difficult to prototype using existing 3D printers, they are often much more expensive and complicated to manufacture. In this webcast, we discuss a unique process called Projection Micro Stereolithography (PµSL) for printing true microstructures with ultra-high resolution (2µm~50µm) and tolerance (+/- 10µm ~ +/- 25µm). Tune in to learn: Why PµSL is a game changer in electrical, medical, and microfluidic applications; How to prepare your design files (CAD models) for micro-scale printing; AM's…

Found in Robotics News & Content, with a score of 24.43

…conferences. Guha teaches a graduate lab course on metal additive manufacturing (AM) and design, which typically involves designing and producing parts in AM hardware. With everyone staying home and connecting via individual webcams from separate places, how can this class continue? Somehow, Guha and his students found a way. “Before the [Coronavirus] outbreak, the class was divided into smaller groups. We had round-robin schedules, with one group working on reverse-engineering, one on manipulation of the point-cloud [scan] data, one group on setting up the build plate, and one group on process simulation,” he recalled. “[Teaching on Zoom video conferencing] is…

Found in Robotics News & Content, with a score of 24.43

…conferences. Guha teaches a graduate lab course on metal additive manufacturing (AM) and design, which typically involves designing and producing parts in AM hardware. With everyone staying home and connecting via individual webcams from separate places, how can this class continue? Somehow, Guha and his students found a way. “Before the [Coronavirus] outbreak, the class was divided into smaller groups. We had round-robin schedules, with one group working on reverse-engineering, one on manipulation of the point-cloud [scan] data, one group on setting up the build plate, and one group on process simulation,” he recalled. “[Teaching on Zoom video conferencing] is…

Found in Robotics News & Content, with a score of 19.06

…the pandemic. With its rapid and distributed production capabilities, additive manufacturing technology was literally built for such a moment. Printer manufacturers, technology companies, and engineers are stepping up to help fill the gap in the medical supply chain—and more help is needed. Universities (and some high schools, and individuals working in livings and garages) across the country have converted their engineering departments and 3D print labs into make-shift factories for churning out PPE. On-demand manufacturing and prototyping operations, as well as manufacturers of other types of products, have converted all or part of their capacity to address the shortages. Hobbyists…

Found in Robotics News & Content, with a score of 35.64

ArcelorMittal and Additive Industries joined forces to focus on 3D metal printing for the steel industry using a large 4-laser 3D metal printing system: the MetalFAB1. 3D printing of spare parts ioffers on-demand, on-location production; it also shortens the production cycle and enables flexibility to ArcelorMittal plants. Since the installation of the first metal 3D printer in ArcelorMittal R&D facilities, several 3D-printed spare parts have already been used while others are still running in ArcelorMittal facilities. The MetalFAB1 is a metal printer that has automated the manual steps of conventional powder bed fusion (PBF) printers. Its build volume (420x420x400 mm)…

Found in Robotics News & Content, with a score of 36.37

…next phase of the COVID-19 Health Care Needs and Additive Manufacturing (AM) Capabilities Repository, where additive manufacturers can upload 3D print designs to be reviewed and placed on the NIH 3D Print Exchange. Designs submitted through the America Makes design submission form in connection with NIH 3D Print Exchange, will be placed in a fast track workflow for faster review. Designs not submitted through the America Makes process may not be considered for the fast track workflow. All designs will be publicly accessible through the NIH 3D Print Exchange website with their designation. “We have seen so much innovation throughout…

Found in Robotics News & Content, with a score of 23.66

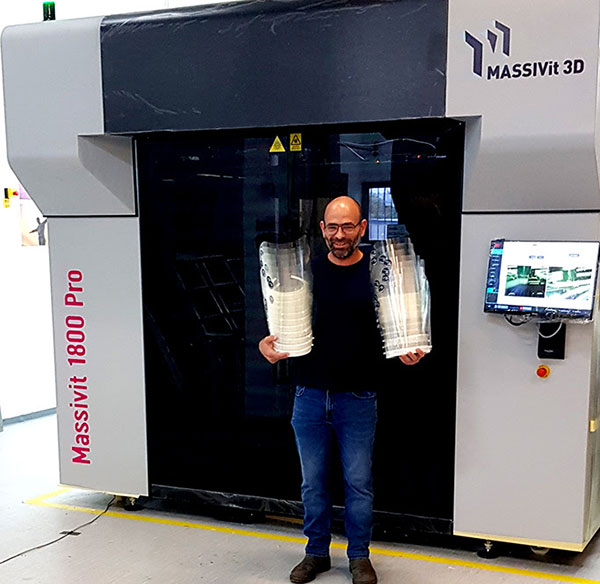

…for the victims of the pandemic. Massivit 3D’s high-speed additive manufacturing technology allows for the supply of hundreds of face shields off each machine every day. In addition to devoting all of its manufacturing resources to producing and donating thousands of face shields to medical teams at local hospitals with a less than one-day turnaround, the company has also made available to all, the optimized 3D print files of the newly developed face shields. The Massivit 3D global network of customers and distributors are also making Massivit 3D printers available for this effort, supplying face shields to health workers in…

Found in Robotics News & Content, with a score of 6.02

…that are being introduced into the sectors such as additive manufacturing and 3D printing also have a huge potential to cause big disruptions to the traditional transportation and logistics model and can cause enablement of newer and more decentralized business models. For example, instead of having to transport specific products, this need can be replaced by a 3D printing on-site in many cases. This, therefore, opens up an opportunity for the providers of contract logistics to add 3D printing service to what they offer, consequently leading to the last-mile customization. 5. Advanced Technology Adds A New Means of Physical Transportation…

Found in Robotics News & Content, with a score of 36.06

During the 8th edition of the Additive World Conference, chairman of the Jury, Ultimaker’s Steven van de Staak, announced K3D and Younes Chahid as winners of the Additive World Design for Additive Manufacturing Challenge 2020. All finalists, three in the student category and three professionals, pitched their designs in a video for the six-member jury. After deliberation they made a unanimous and well-advised selection in both categories. The winning designs, a “Laser Welding Head” and a “Hip Implants Stem Design,” are use cases of industrial 3D metal printing. In the student category the first prize went to Younes Chahid from…