Editors’ Picks

Found in Robotics News & Content, with a score of 7.87

…(IATA)'s EMG to be able to realize additively manufactured plastic cabin parts. “Both additive manufacturing users and producers will benefit from implementing AMS-AM standards,” says Paul Jonas, director of Technology Development & Programs at the National Institute for Aviation Research (NIAR) and AMS-AM-P Chair. “These standards help define a consistent set of materials and process limits that both the user and producer agree to in support of part procurement activities. AMS-AM standards support the promotion of knowledge, standardization of practice and advancement of commerce in the emerging AM aerospace industry.” The AMS7100 specification establishes the controls and requirements to produce…

Found in Robotics News & Content, with a score of 11.53

…into one operation. The robots handle perishable goods in plastic crates in the refrigerated zones. Although fully integrated with the surrounding manual operations, the system is effectively an island of automation that prepares orders for retail stores, enabling them to be transported to the supermarkets without the need for any further processing. With product pallets going in and store pallets coming out, the island is self-sufficient, taking care of goods reception; put-away; location of stored items; retrieval planning; picking of crates; sorting and assembly of crates into discrete orders; and loading of the orders onto transport units ready for delivery.…

Found in Robotics News & Content, with a score of 8.02

…replacement—continuous carbon fiber composites—that can be combined with metals, plastics, wires, and other materials for aerospace, automotive, and consumer products. In a recent press release, Ethan Escowitz, founder and CEO of Arris Composites, explains: “The product architectures that are now possible with our high-volume manufacturing process unlock a host of competitive advantages for some of the highest revenue and highest value products in the world. Vehicles and consumer products are being redesigned to take advantage of the mass market manufacturing technology of tomorrow. Things are about to get lighter and smaller, and Arris is making that a reality.” Arris states…

Found in Robotics News & Content, with a score of 30.96

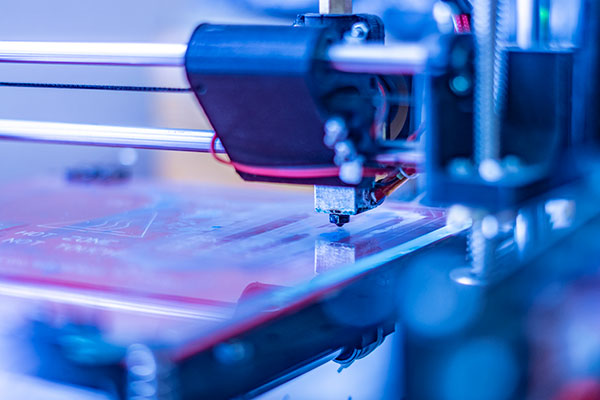

…manufacturing applications that enables manufacturers to directly produce end-use plastic parts without tooling. This results in parts produced the same day versus weeks required with conventional tool-based approaches. Figure 4 PRO-BLK 10 is 3D Systems’ photopolymer for additive manufacturing that exhibits thermoplastic behaviors, providing a combination of speed, accuracy, strength and durability previously only associated with injection molding output. The material works with a simple isopropyl alcohol (IPA) wash and does not require a secondary thermal post-cure process, which significantly improves throughput yield and significantly reduces the extensive solvent cleaning cycles needed with other technologies. In customer testing of a…

Found in Robotics News & Content, with a score of 6.23

…with finer details than most processes that use high-strength plastics. The composition is one of the more isotropic available from additive manufacturing. How does the technology work? SLS uses a blade to spread a thin layer of powder over the build volume. A laser sinters the cross-section of the part, fusing the powder together. The z stage then drops one layer, and the process begins again until the build is finished. Parts are then excavated from the build powder-cake and bead blasted. The un-used powder in the build envelope acts as the support structures, so no support removal is necessary.…

Found in Robotics News & Content, with a score of 12.48

…The additive technologies most commonly used for production of plastic parts include Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Multi Jet Fusion (MJF). The break-even point of AM compared to injection molding (IM) was once a few hundred parts but is now pushing into the thousands with trends showing the cut-off point even higher in the coming years. Although, if you are projecting production volumes in the 10’s, 100’s of thousands, or even millions, AM can still prove to be a strong option for manufacturing throughout the early stages of production. AM has many other benefits not explicit…

Found in Robotics News & Content, with a score of 12.68

…MaaS evolution to that of other industries, such as plastics injection molding, where the concept is successful. “Injection molding output [IMO] is sold as a service, instead of purchasing an injection molding press, auxiliary equipment and robotics,” he says. “All traditional equipment purchases require technical support and trained employees to optimize processes for each unique project. Current financial and timing hurdles must be overcome in the competitive race to get products quicker to market.” Heverly says IMO is the plastic industry’s take on a share economy. OEM suppliers are selling moldable hours or pounds. “A complete documented process that is…

Found in Robotics News & Content, with a score of 11.40

…with Wittmann Battenfeld, a global manufacturer and supplier of plastics processing equipment on July 5, to collaborate on new innovations in liquid silicone rubber (LSR) injection molding. The MoU was signed on behalf of Moldex3D by Dr. Rong-Yeu Chang, CEO and on behalf of Wittmann Battenfeld by David Chen, President of Wittmann Battenfeld Taiwan. The MoU is aimed at bringing together both parties’ extensive knowledge and technical expertise to advance the role of simulation in LSR injection molding. As part of the partnership, Moldex3D has acquired LSR injection molding equipment, including SmartPower 90/350 UNILOG B8 from Wittmann Battenfeld and LSR…

Found in Robotics News & Content, with a score of 9.23

…has chosen DuraForm ProX HST Composite, a fiber-reinforced engineered plastic that combines rigidity and thermal resistance and is designed for the manufacture of structural elements, housings, coatings, covers, knobs, handles, masks, equipment and internal components for the automotive industry. “The implementation of this new technology dedicated to 3D printing, with a second machine already optioned, is just one of many upgrades that we have planned for 2019 and that will allow us to respond even more thoroughly to the demands of this market, where we register a vertical growth with runs that involve thousands of units,” says Rigamonti. Weerg Srl…

Found in Robotics News & Content, with a score of 9.38

…have use for individualized decorative trim in vehicles and plastic design products, according to the company. For users, 4D_Additive makes it easy to define textures on the CAD model, simply choosing the desired B-Rep areas and a matching texture from the database. The fineness and position of the structure can be visually adjusted on the component. The software automatically ensures distortion-free projection of the grain over surface boundaries. The graphical representation allows the assessment of the designed geometry and fuels the creative process in the design of new parts. The tool reads CAD data from all common systems such as…

Found in Robotics News & Content, with a score of 32.65

…Report. In addition to a commitment to increase recycled plastic content in its Personal Systems and Print products to 30% by 2025, the technology giant also set a timeline to power its global operations with 100% renewable electricity by 2035. On the recycled plastics front, HP announced it used 21,250 tonnes of recycled plastic in HP products, including more than 8,000 tonnes in its Personal Systems products (an increase of 3.5% from 2017), more than 4,700 tonnes in its printing products (a much more significant increase of 280% during the same timeframe), and more than 8,000 tonnes in its ink…

Found in Robotics News & Content, with a score of 2.31

…teams had to determine the format and number of plastic totes each robot would carry. IT work focused on integrating GEODIS’s WMS with the robot management system and creating a digital warehouse map that the robots would follow. Add in training time and change management sessions with the 60 team members who would be involved with the robots, and the prep work took roughly two months before the October 2017 go live with 30 robots. “We emphasized that the robots were not there to replace associates, but to improve their productivity,” Stock recalls. That effort paid off and the associates…