Editors’ Picks

Found in Robotics News & Content, with a score of 8.48

…Nguyen, Carnegie Mellon Robotics Academy “Machine Learning Augmented Youth Welding Training Support from Ideation, Planning, to Manufacturing” — Dina El Zanfaly, CMU School of Design and Daragh Byrne, CMU School of Architecture “New Bridges to the Digital Economy” – Lee Branstetter, CMU Heinz College Grants spurs employment opportunities Stefani Pashman, CEO of the Allegheny Conference on Community Development, praised CMU’s Build Back Better Regional Challenge grant in the award announcement announcement. She observed that projects funded through the grant will help create employment opportunities for Pennsylvania residents. “Autonomy has the potential to catalyze exciting, well-paying, next-generation jobs across Southwestern Pennsylvania,…

Found in Robotics News & Content, with a score of 8.44

…new automation opportunities in precision areas such as arc welding, mobile phone display electronics assembly, gluing, and laser cutting. Overall, OmniCore enables robots to operate up to 25% faster and to consume up to 20% less energy compared to the previous ABB IRC5 controller. OmniCore is built on a scalable, modular control architecture that offers a wide array of functions to create almost any application imaginable, making it suitable for businesses embracing automation in existing and new segments, such as biotechnology and construction. Software and hardware options to design, optimize operations With over 1,000 hardware and software features, customers can…

Found in Robotics News & Content, with a score of 8.42

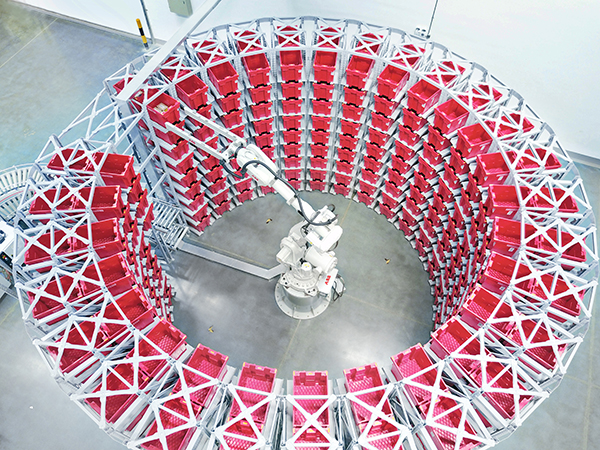

…some examples. Most of the collaborative robot suppliers showed welding cells, with Universal Robots leading the way with its first cobot TIG welding and spot welding applications with partners THG Automation and Pro Spot, respectively (see video below). Kane Robotics and FerRobotics used a UR cobot to demonstrate grinding and surface finishing (see photo, top right). Affordability and ease of use were important, as igus demonstrated with its low-cost automation line at Automate. The motion plastics supplier openly listed the prices for all its robots, components, and preassembled workcells. Combinations of different robots were also noteworthy. FANUC showed an order-fulfillment…

Found in Robotics News & Content, with a score of 8.38

…been kept. While in one sector alone, the American Welding Society says the US will face a shortage of 400,000 welders by 2024. ABB’s study also found that American companies are relying more on automation to solve their supply chain woes. 43% of businesses surveyed indicated that they will use automation and robotics to build supply chain resilience, with 75% of US-based businesses noting that robotics and automation will play a significant role in addressing supply chain issues. Europe bullish on robotics Although there is a greater demand for robotics in the United States, ABB’s survey found that the rate…

Found in Robotics News & Content, with a score of 8.35

…barrier of transitioning legacy parts, historically produced by casting, welding, or brazing, to additive manufacturing, it said. “For Chromalloy, 3D printed parts must provide inherent value because they are 3D printed,” said Jim Whitton, director of innovation strategy at Chromalloy. “Otherwise, the printing itself is just a novelty. VELO3D’s unique build capability and material density create high value by reducing post-processing requirements.” VELO3D said all Sapphire laser powder-bed machines come standard with its highly automated, user-friendly Flow pre-print software and Assure quality assurance (QA) and control system. Partners expect to expand in MRO markets “As an industry leader in the…

Found in Robotics News & Content, with a score of 8.35

…“Rocket engine turbopump parts typically require casting, forging, and welding,” said Max Haot, founder and CEO of Launcher. “Tooling required for these processes increases the cost of development and reduces flexibility between design iterations. The ability to 3D print our turbopump—including rotating Inconel-shrouded impellers, thanks to Velo3D’s zero-degree technology—makes it possible now at a lower cost and increased innovation through iteration between each prototype.” Inconel is a family of nickel-chromium-based superalloys trademarked by Special Metals Corp. It is used extreme industrial or space environments, like titanium, which has a high strength-to-density ratio. Founded in 2017, Launcher is developing a rocket…

Found in Robotics News & Content, with a score of 8.32

…tooling for applications in sheet metal forming, composite layups, welding fixtures, molding, casting patterns and end-use parts on Titan Atlas printers to meet a need for increased part strength and faster printing speeds, companies say. Jabil’s specialized materials science expertise, combined with Titan’s robust printing performance, are ideally suited for addressing the growing list of rigorous industrial, as well as medical, defense and aerospace applications. “Titan and Jabil are fulfilling a joint mission to move additive manufacturing into serial production and advanced manufacturing,” says Titan Robotics partner and CTO, Bill Macy. “By choosing Jabil’s engineered materials customized for applications with…

Found in Robotics News & Content, with a score of 8.14

…allows six-axis robots to do more things, such as welding, palletizing, and machine tending, explained Richard Vaughn, a senior automation engineer at Bosch Rexroth Corp. and a member of the American Society of Mechanical Engineers (ASME). “Programming their movements in 3D is complex, so software typically maps the motion to a set of world coordinates, in which the origin sits on the pedestal’s first joint axis,” he said. Five- and six-axis: The sweet spot? Four-, five-, and six-axis robots offer a higher degree of freedom. Most industrial robots today are either five- or six-axis. They can move along all three…

Found in Robotics News & Content, with a score of 8.10

…to connect existing automated processes, such as machining centers, welding cells, packaging cells, palletizers, or stretch wrappers. “OTTO is the best AMR that I’ve worked with; ensuring the right materials are delivered safely and efficiently every time,” said Tony Margiotta, president of Sunview Patio Doors. “OTTO has exceeded our expectations, and Phase 2 of implementation is already under way to expand our fleet.” Fleet services offered OTTO Motors added that it offers comprehensive fleet-service plans and a global network of certified partners for lifecycle fleet management. “At Mauser Packaging, we are continually innovating our processes and technology to improve our…

Found in Robotics News & Content, with a score of 8.07

…VR offerings. The company's technology is incorporated into the welding and vehicle spray painting applications deployed by Lincoln Electrics and Honda, among others. In Flaim Systems' firefighting applications as well as Sixense's training apps, the use of replica equipment plays an important role. In Flaim Trainer, users use a haptic-enabled water nozzle that can simulate water pressure. In Sixense's spray simulation application, users use an industry-standard paint gun. The incorporation of eye tracking, hand tracking, and replica equipment that help build muscle memory brings AR-VR-powered training to a new level, setting it apart from entertainment applications that focus primarily on…

Found in Robotics News & Content, with a score of 8.06

…advantage of some semi-automated processes for CNC machining and welding, but it's hoping to invest in a robotic arm or two to help with welding and cutting. Helfrich Brothers Boiler Works, like many small and medium-sized enterprises, is looking to automation to help increase productivity and throughput and to address labor challenges. And like other smaller companies, it's looking to outside sources to help pay for them. Helfrich looks to state to help fund robot project Helfrich Brothers Boiler Works is one of many of Massachusetts companies that applied for a Massachusetts Manufacturing Accelerate Program grant (MMAP). The program is…

Found in Robotics News & Content, with a score of 8.00

…suppliers were handling and picking (69% of suppliers), assembly (45%), inspection and quality assurance (32%), machine tending (29%), and welding (27%). Many of the companies and technologies mentioned in the report will be on full display at the Automate Show in Detroit from June 6 to 9, 2022. Registration is free and available now.