Editors’ Picks

Found in Robotics News & Content, with a score of 6.79

…incredibly exciting and rewarding to be part of the robotics adventure in Odense since the 1980s, when I developed welding robots for the Odense Steel Shipyard,” he said. The Danish robotics cluster currently consists of more than 300 robotics and automation companies.

Found in Robotics News & Content, with a score of 12.55

…large selection of standard utility modules and tool stands, enabling a wide array of unique configurations, ranging from ultrasonic welding to servo motor support and more.

Found in Robotics News & Content, with a score of 11.24

…robots during any downtime. After already seeing promising results, Polar has signed another contract with Formic to add a spot-welding robot into its facility. The company is also considering moving from a two-shift operation to a three-shift operation, allowing the cobots to run around the clock. Altogether, with both systems up and running, Polar said it expects to save around $150,000 per year in operations costs.

Found in Robotics News & Content, with a score of 5.97

…which is a very positive long-term story.” “For instance, welding is becoming a pretty hot area,” said Burnstein. “This includes small metalworking shops for all kinds of products, but we don't classify it in great detail.” “While we're still not seeing huge numbers in agriculture and construction, we know there are opportunities,” he said. “But we are seeing life science, pharmaceutical, medical devices, food processing, and consumer goods segments going up.” “If anything, we're under-reporting the growth in sales of all types of robots,” he acknowledged. “We don't have numbers on AMRs [autonomous mobile robots] or collaborative robots yet, and…

Found in Robotics News & Content, with a score of 10.32

…components, but the main jobs of robots are still welding chassis and moving heavy parts. We also have battery production, which is something where robots are crucial.” The operational stock of robots has increased by 10% since 2019, and it experienced a compound annual growth rate (CAGR) of 9% from 2015 to 2020, said Müller. “The level of installations has been climbing over the past decade,” he said. “There was slowed growth in electrical, but increases nearly everywhere else.” Source: International Federation of Robotics The IFR's 350-page World Robotics 2021 reports for industrial robots and service robots can be ordered…

Found in Robotics News & Content, with a score of 6.06

…across a wide range of industry for tasks from welding to painting to material handling. Industrial robots in automotive assembly. Source: SwRI Traditional robots are isolated from humans by cages with complex safety systems in place to ensure that workers cannot be injured while the robot is moving. This is essential because a traditional robot is a heavy piece of machinery moving at high speeds. Without a safety system in place, an industrial robot can easily injure or kill someone if they accidentally move into its path. With enough safety measures, it is possible to incorporate most traditional industrial robots…

Found in Robotics News & Content, with a score of 13.82

…industrial and collaborative robot makers are offering systems for welding and other industrial applications. Robotics 24/7 has already covered several welding robots, and here are other systems that captured attendee attention at Fabtech 2021: AGT Robotics LayoutMaster AGT Robotics' LayoutMaster is a full-color laser projection system designed to project all the information that an operator needs to accurately tack-weld connections on the beam or on other connections. The LayoutMaster projects complete and comprehensive information, including 3D contours, holes, holes center, welding information, part numbers and other details. Thus, an operator with limited training can align the connection with the projected…

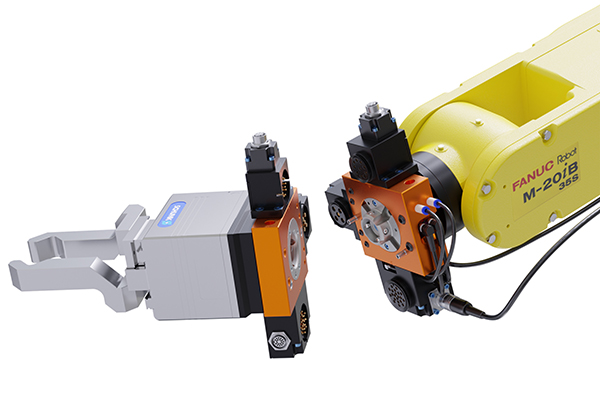

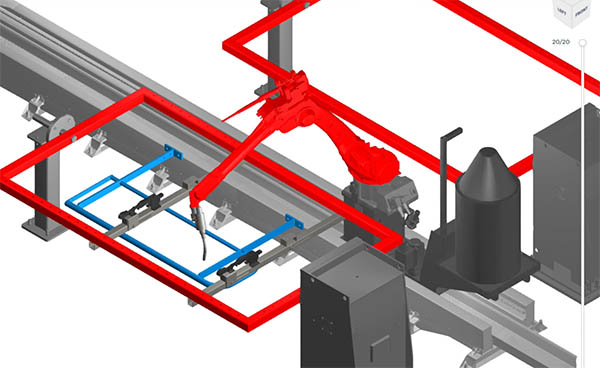

Found in Robotics News & Content, with a score of 38.32

…automation continues to grow. The global market for robotic welding and peripherals could experience a experience a compound annual growth rate (CAGR) of 6%, growing by $2.3 billion (U.S.) between 2021 and 2025, according to Research and Markets. Similarly, Markets and Markets projected a 10.5% CAGR, with the market growing from $7.1 billion (U.S.) in 2021 to $11.7 billion by 2026. Source: Markets and Markets Cobot welders add features Among the features that collaborative robot providers demonstrated at this year's event were increased reach, vison-based guidance, and interfaces for ease of use. Vendors also touted cable management, new sensors, and…

Found in Robotics News & Content, with a score of 28.02

…that manufacturers cannot find enough humans to fill the welding and other fabrication needs that they have. Robots could alleviate worker shortage, says UR The American Welding Society (AWS) estimates there is currently a shortage of 50,000 welders. It expects that figure to grow to nearly 400,000 by 2024, as many of today’s welders, who are now an average age of 55, retire. Welding is no longer part of shop classes in high schools, and some of the work is extremely repetitive in nature, not work a welder wants to do, said Joe Campbell, senior manager of applications development at…

Found in Robotics News & Content, with a score of 7.20

…use of 3D printing and other technologies, including robotic welding, machining, finishing, and inspection operations, in full production environments. The company added that its system can benefit vertical sectors including dentistry, aerospace, and automotive. To fill this need most effectively, Oqton said it will operate as an independent organization and solution platform within 3D Systems, with data confidentiality and security protocols assured through third-party verification. 3D Systems expands offerings 3D Systems also announced that it will expand availability of its most advanced software—3DXpert, 3D Sprint, the Geomagic portfolio, and Additive Works Amphyon—as optional add-ons to the Oqton MOS platform. With…

Found in Robotics News & Content, with a score of 8.35

…“Rocket engine turbopump parts typically require casting, forging, and welding,” said Max Haot, founder and CEO of Launcher. “Tooling required for these processes increases the cost of development and reduces flexibility between design iterations. The ability to 3D print our turbopump—including rotating Inconel-shrouded impellers, thanks to Velo3D’s zero-degree technology—makes it possible now at a lower cost and increased innovation through iteration between each prototype.” Inconel is a family of nickel-chromium-based superalloys trademarked by Special Metals Corp. It is used extreme industrial or space environments, like titanium, which has a high strength-to-density ratio. Founded in 2017, Launcher is developing a rocket…

Found in Robotics News & Content, with a score of 31.97

…said that it plans to unveil its new Spool Welding Robot+HyperFill technology at the FABTECH event next month in Chicago. The dual-torch system can increase heavy fabrication productivity to 350 to 500 factored diameter inches, or FDI, per shift by increasing weld deposition rates, said the Vancouver, British Columbia-based company. This can lead to increased efficiency, it said. “With Novarc’s SWR+HyperFill, pipe-fabrication shops are guaranteed higher performance by being able to increase weld deposition rates and deliver excellent weld quality,” said Soroush Karimzadeh, CEO of Novarc. “[It can also reduce] weld and material handling costs compared to the sub-arc process…