Editors’ Picks

Found in Robotics News & Content, with a score of 39.35

…80kg (176 lbs.), making them options for palletizing and machine-tending applications. This series of robots connect to a wide range of factory automation equipment to seamlessly integrate robot functionality with IT systems. “The RV-35/50/80FR series is going to be a game changer for Mitsubishi Electric,” said Curtis Sylliaasen, product manager (robot), at Mitsubishi Electric. “These heavier-payload robots give us the ability to do applications that were previously inaccessible to us, such as end-of-line palletizing and machine tending for large parts.” RV-35/50/80 is engineered to work seamlessly in manufacturing environments through a wide range of safety functions, including position and speed…

Found in Robotics News & Content, with a score of 38.85

Automation for unstructured picking and placing of parts into machines typically relies on computer vision, which often requires additional programming, according to Universal Robots ApS. This is necessary to bridge the gap from “pick” to “place” – especially if the “place” is not just dropping items into a box but accurately inserting parts into fixtures for further processing, said the company. ActiNav combines real-time autonomous motion control, collaborative robots, vision, and sensor systems in one Application Kit to solve the random bin-picking challenge, claimed Universal Robots. To help manufacturers integrate ActiNav into machining cells, the Odense, Denmark-based cobot maker yesterday…

Found in Robotics News & Content, with a score of 38.77

…each step of a task or job. The plug-and-play machines are engineered to work with new or legacy equipment and have the flexibility to perform both simple and complex activities, it said. Productive Robotics’ cloud analytics system streamlines connectivity requirements for nimble data collection and reporting. Installation for the kitted OB7 cobots is simple and quick and can be performed whether an application calls for repetitive part work, tending a CNC machine or manning a lights-out operation. “Cobots augment and enhance a fabricator’s capabilities with precision, repeatability, and tireless performance, freeing employees from tedious, repetitive activities so that they can…

Found in Robotics News & Content, with a score of 36.74

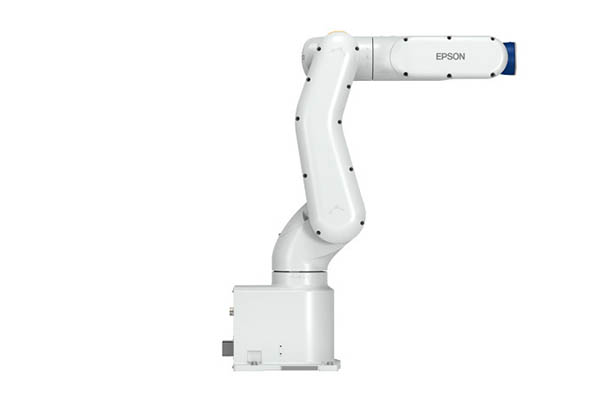

…robot arm will be popular for material transfer and machine tending applications. Customers in those industries want the flexibility of having a robot arm that can more freely navigate a facility and be used in many parts of a supply chain operation at any given time. That can be useful in situations where a facility has multiple machines spread throughout a facility that run at different times and require items to be loaded and unloaded, she noted. “Now you can put a robot on a mobile workstation and move it between operating centers,” she said. Updates to Epson RC+ Express…

Found in Robotics News & Content, with a score of 36.50

…will focus on three applications within industrial automation: welding, machine tending, and palletizing. The events will be broadcast live from Universal Robots’ three Centers of Excellence across the globe. Palletizing: Sept. 28 from Barcelona, Spain Machine tending: Oct. 12 from Munich, Germany Welding: October 26 from Novi, Mich. The company said all three events are free to attend, and they will feature: Talks with experts and industry leaders Successful customer case stories Live demonstrations of the latest UR20 robots Live Q&A sessions with industry experts Universal Robots provided more information and free registration at its website. UR cobots conduct machine…

Found in Robotics White Papers & Archives, with a score of 36.16

…edge, autonomous systems are becoming more capable. Learn about how robots are becoming more capable for applications such as machine tending, pick-and-place operations, and welding. The free download also examines how these technologies are improving robot and vehicle navigation. In addition, automation is spreading beyond manufacturing to for agriculture, e-commerce, and more. Topics covered include: Innovations in cameras, lidar, and collaborative robotics How picking robots are getting faster and more accurate AI and programming enable more thorough inspections Robotics providers receive recognition as innovators How robots are shaping the future of industry

Found in Robotics News & Content, with a score of 33.50

…the respondents indicated they are now using AI and machine learning in their production processes. At IMTS 2024, UR showed a machine-tending application with new AI-based perception capabilities running on NVIDIA Jetson and Isaac acceleration libraries integrated into UR’s new PolyScope X platform. This combination enables dynamic path planning, ensuring the robot takes the most effective, collision-free paths in and out of the machine without requiring extensive user configuration. UR plans to make this technology available for a wide range of applications, including machine tending and other material handling tasks. “AI isn’t just hype,” said Ujjwal Kumar, group president of…

Found in Robotics News & Content, with a score of 33.40

…it is also quickly raising funding for its robotic machine operator. In its third fundraising in less than a year, the San Francisco startup today announced a $36.7 million Series B round. The company said its Rapid Machine Operator enables manufacturers to deploy a pretrained collaborative robot in hours without any specialized skills, systems integration, or programming. Since emerging from stealth in late 2020, Rapid Robotics said it has addressed the needs of American manufacturers as they face a labor shortage aggravated by the COVID-19 pandemic. According to a recent study from Deloitte and The Manufacturing Institute, by the end…

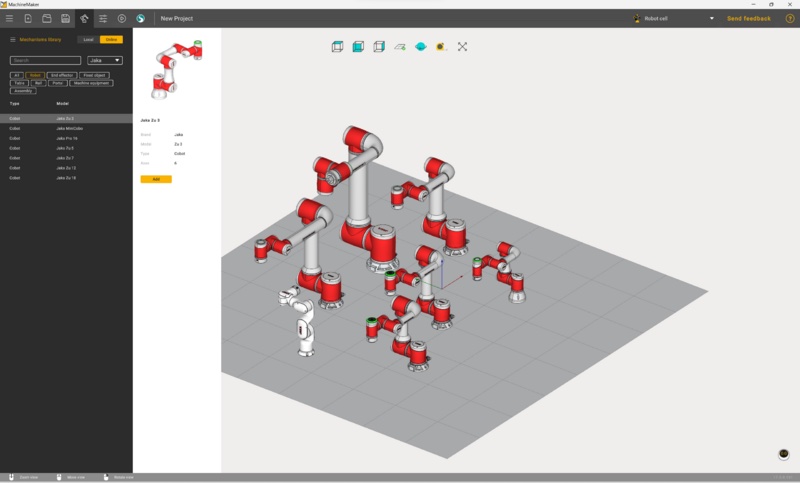

Found in Robotics News & Content, with a score of 33.14

…is expanding its technological partnerships with manufacturers of CNC machines and industrial robots. The online library of robot components has been updated to include digital twins of the popular JAKA cobots from the well-known Chinese manufacturer. The complete list of supported equipment is found on this dedicated page. https://sprutcam.com/component-library/ JAKA Robotics collaborative robots are deployed in applications in various industries such as machining, automotive, electronics, semiconductor, and more. These cobots, known for their compactness, safety, and power, offer payload ranges from 3kg to 18kg and repeatability between ±0.02 and ±0.03mm. They are versatile, used in assembly, welding, machine tending, inspection,…

Found in Robotics News & Content, with a score of 32.95

…that robotics can play in plastics injection molding: 1. Machine tending A common application for pick-and-place systems is the loading and unloading of products into packaging. In plastics, machine tending robots can unload finished parts from the injection-loading machine and deliver them to downstream processes. Using pick-and-place automation, such as Cartesian robots and Delta robots, can reduce the risk of injuries to laborers, as well as improve product consistency and production capacity. 2. Insert molding Insert molding is another task often handled by robots. Insert molding entails enclosing an “insert” such as a pin, blade, or threaded rod in molded…

Found in Robotics News & Content, with a score of 32.43

…ABB Value Provider MESH Automation; a vision guided FlexLoader machine tool tending cell; and the Cobot FlexTrainer education cell for interactive classroom training. “ABB has continually developed cutting-edge products and support programs to help a wide variety of manufacturers and their employees become more productive, resilient and adaptable. Our IMTS exhibit will showcase a number of these innovations, many of which have opened up robotic automation to a broad group of first-time users,” said Joe Chudy, U.S. general manager at ABB Robotics. “Now, more than ever, businesses of all sizes need to embrace robotics to efficiently adapt production to satisfy…

Found in Robotics News & Content, with a score of 31.98

Kassow Robots, a developer of 7-axis cobot systems for machine tending, material handling, and related applications, announced last that week that its KR1018 7-axis cobot is being deployed as part of a solution to automate the textile industry. The 7-axis KR1018 has a payload of 18kg (39 lb.) and a reach of 1000 mm (39 in.), making it the ideal machine to complete precise and repetitive industrial tasks that require great strength, the company said. An AGV/cobot combo system The cobot will be mounted on an AGV equipped with a magazine and control system and used to restock cabling machines,…