Editors’ Picks

Found in Robotics News & Content, with a score of 44.21

The National Center for Defense Manufacturing and Machining (NCDMM), parent organization of America Makes, has entered into a formal collaboration agreement with Digital Engineering, to advance the additive manufacturing/3D printing industry. America Makes and its membership community of more than 220 organizations share a common goal to accelerate additive manufacturing and 3D printing to increase the U.S. global manufacturing competitiveness. Digital Engineering will help leverage its magazine, e-newsletters, DigitalEngineering247.com website and marketing database to drive awareness of America Makes’ mission as national accelerator for additive manufacturing and 3D printing. “Digital Engineering (formerly Desktop Engineering) has been covering additive manufacturing and…

Found in Robotics News & Content, with a score of 43.70

…and performance requirements in the aerospace sector. ASTM International’s additive manufacturing technologies committee (F42) is currently developing the four standards. “The industry uses standards to ensure that public safety, quality, and readiness levels are maintained,” said Shane Collins, general manager at Additive Industries North America and an ASTM member. “Once approved, these standards could be used to certify that parts are manufactured to the highest quality levels required by the U.S. Federal Aviation Administration [FAA] through the part and process qualification procedures.” According to Collins, the new standards could help civil, commercial, and military aircraft manufacturers, as well as producers…

Found in Robotics News & Content, with a score of 43.55

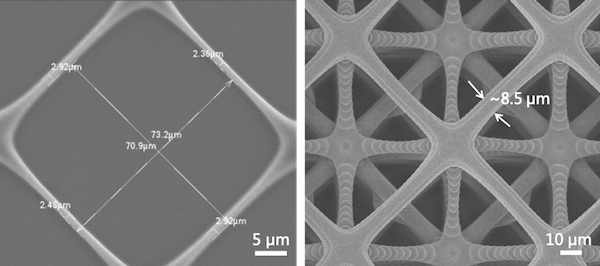

…PT Register Today! One of the new frontiers in Additive Manufacturing (AM) is the production of high-resolution, high-accuracy microstructures for industrial applications. These parts are not only difficult to prototype using existing 3D printers, they are often much more expensive and complicated to manufacture. In this webcast, we discuss a unique process called Projection Micro Stereolithography (PµSL) for printing true microstructures with ultra-high resolution (2µm~50µm) and tolerance (+/- 10µm ~ +/- 25µm). Tune in to learn: Why PµSL is a game changer in electrical, medical, and microfluidic applications; How to prepare your design files (CAD models) for micro-scale printing; AM's…

Found in Robotics News & Content, with a score of 43.49

Protolabs has teamed with additive manufacturing (AM) consultants Wohlers Associates in a joint effort to accelerate design for manufacturing knowledge around 3D printing. The immersive course is created to help engineers and designers develop practical methods and strategies to get the most from different 3D printing technologies. The invitation-only course titled Designing for Additive Manufacturing (DfAM) takes place over 3 days near Raleigh, NC, concluding at Protolabs’ 77,000-sq.-ft. 3D printing facility. Leading the discussion are Olaf Diegel, associate consultant at Wohlers Associates, along with Terry Wohlers, principal consultant and president at the company. Diegel also serves as head of the…

Found in Robotics News & Content, with a score of 43.42

Evonik Corporation and Evolve Additive Solutions, Inc. have announced a joint development agreement where the companies will work together to formulate Evonik’s thermoplastic materials to be used in Evolve's selective thermoplastic electrophotographic process (STEP) additive manufacturing solutions. The initial development efforts will focus on polyamide 12, PEBA, transparent polyamide, and polymer of the polyamide 6 series. Evolve’s STEP technology will operate alongside traditional manufacturing processes, such as injection molding on the manufacturing floor, augmenting an organization’s production capabilities and allowing freedom of design and faster time to market with “toolless” production. The selective thermoplastic electrophotographic process from Evolve is still…

Found in Robotics News & Content, with a score of 43.29

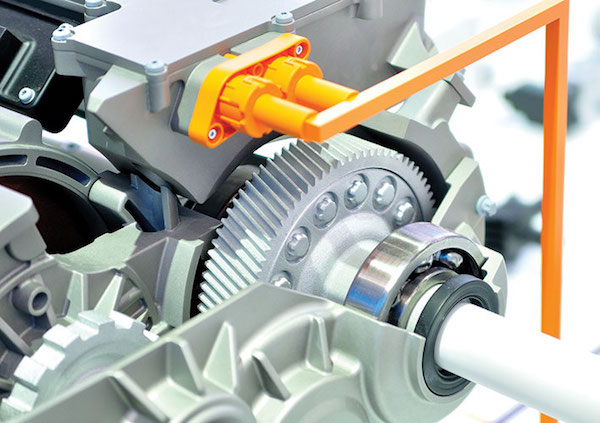

Renishaw, a precision engineering and manufacturing technologies company, worked with Michigan-based Cobra Aeroto to improve the engine manufacturer’s design processes for aircraft and motorcycle engines. After completing the project with Renishaw, Cobra Aero invested in an AM 400 system to increase its in-house additive manufacturing (AM) capabilities. To optimize the design of its engine cylinders and to gain expertise in AM, Cobra Aero visited a Renishaw Additive Manufacturing Solutions Center. There they collaborated with Renishaw engineers to discover how AM could improve the design of a cylinder for an unmanned aerial vehicle (UAV). “Investing in AM allows us to develop…

Found in Robotics News & Content, with a score of 43.16

…publishes the full volume of ASM Handbook, Volume 24: Additive Manufacturing Processes in ASM Handbooks Online in the ASM Digital Library. The print volume wa scheduled to be published in August 2020. “ASM Handbook, Volume 24: Additive Manufacturing Processes,” edited by David L. Bourell, William Frazier, Howard Kuhn, and Mohsen Seifi, was developed to address the current and rapidly expanding importance of additive manufacturing (AM). This volume provides the latest knowledge in materials, processes and applications of AM, written by the leading experts in research and industry. The handbook begins with an introduction and history of AM, authored by some…

Found in Robotics News & Content, with a score of 43.16

Oerlikon AM, the additive manufacturing unit of technology group Oerlikon, and Siemens AG announce a strategic agreement in which Siemens will provide Oerlikon AM with digital enterprise solutions that will help Oerlikon accelerate the industrialization of additive manufacturing. The integration of Siemens’ Digital Enterprise Portfolio into Oerlikon’s software landscape in its AM production and R&D sites will support Oerlikon in actively managing the AM engineering process from end to end using one interface. The technology includes software solutions in engineering, as well as product life cycle management. The long-term objective is to create a digital factory in which Oerlikon AM…

Found in Robotics News & Content, with a score of 43.02

…developing an industry-accepted guideline for quality assurance of additively manufacturing parts. The consortium includes Equinor, Saudi Aramco, Siemens, Kongsberg Maritime, Voestalpine, Guaranteed, IMI CCI, Kongsberg Ferrotech, Addilan, BMT Aerospace, FIT AG, Howco Group, ImphyTek Powders, Intertek, XDM3D and ExOne. In February, the consortium released a new standard, “Additive manufacturing of metallic parts” ( DNVGL-ST-B203) for the oil & gas sector, which is focused on wire-arc additive manufacturing (WAAM) and laser-based powder bed fusion (PBF-LM). The group is expanding its effort to incorporate more AM technologies, such as binder jetting technology (BJT). “As manufacturers around the world move to new additive…

Found in Robotics News & Content, with a score of 42.95

…directed energy deposition (DED) systems, will demonstrate simultaneous five-axis additive manufacturing at its At RAPID+TCT 2019 booth (#517). The technology is said to enable new capabilities for building, repairing and coating mid- to large-size complex metal parts. The new Optomec LENS additive plugin is toolpath generation software that enables simultaneous five-axis control. When combined with the Siemens Sinumerik 840D CNC, complex geometries can be printed faster and easier, according to Optomec. “Optomec has once again pushed DED printing capability to new heights,” said Tim Bell, additive manufacturing industry manager at Siemens in a press release. “By leveraging the outstanding system…

Found in Robotics News & Content, with a score of 42.87

…as “a robust solution” for delivering CAD-to-print workflows for additive manufacturing. HP says UBM is an OEM- and process-agnostic tool and is supported by many leading vendors. It offers software tools for build preparation, CAD import, patterning, nesting, labeling, support generation and slicing. The Dyndrite engine supports NVIDIA Enterprise GPUs for computational acceleration. It uses Python as a scripting language, and offers various Python application programming interfaces for automation and workflow integration. HP says this new build prep engine will help additive manufacturing engineers and technicians “improve productivity, efficiency and repeatability in their industrial additive production.” “Additive manufacturing has always…

Found in Robotics News & Content, with a score of 42.10

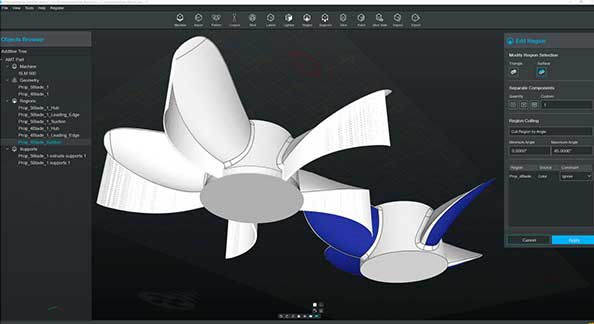

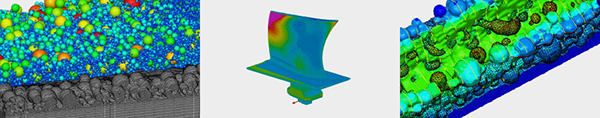

ESI Group has launched the ESI Additive Manufacturing simulation solution suite. The ESI Additive Manufacturing suite, according to the company, provides a comprehensive solution to accelerate metal additive manufacturing (AM) development. ESI adds that the solution suite enables users to quickly address manufacturability issues on the shop floor and that it also connects with material quality investigations. These characteristics, ESI says, make it a “perfect” solution to ensure efficient and continuous workflows from CAD through manufacturing and part qualification. This nacelle hinge was 3D manufactured using a powder bed fusion process. Click here for animation. Image supplied by ESI Group…