Editors’ Picks

Found in Robotics News & Content, with a score of 15.33

…Meltio Robot Cell, which it described as “a turnkey additive manufacturing solution to boost the performance of a industrial robotic arm.” The company said it can improve safety, reliability, and accuracy by controlling the entire process and with its new Meltio Space slicing software. “Meltio's main commitment with the launch of Meltio Robot Cell is to offer all types of industries the ability to manage the entire manufacturing process using our metal 3D printing technology consisting of a Meltio head integrated in a robotic arm and in a safe environment, in order to just produce parts,” said Alejandro Nieto, Meltio…

Found in Robotics News & Content, with a score of 14.38

…CEO of Markforged, in a release. “Every day a manufacturing line is down due to broken or worn parts can cost millions of dollars in lost productivity.” “Availability of spare parts is critical to manufacturers’ success — but keeping an extensive physical inventory ties up capital in parts that may go untouched for years,” he noted. “Digital Source not only can simplify logistics, but [it] can also build resiliency into the supply chain and increase profitability as a result of these efficiencies. With Digital Source, parts can be digitized and printed at the time and point of need without the…

Found in Robotics News & Content, with a score of 20.94

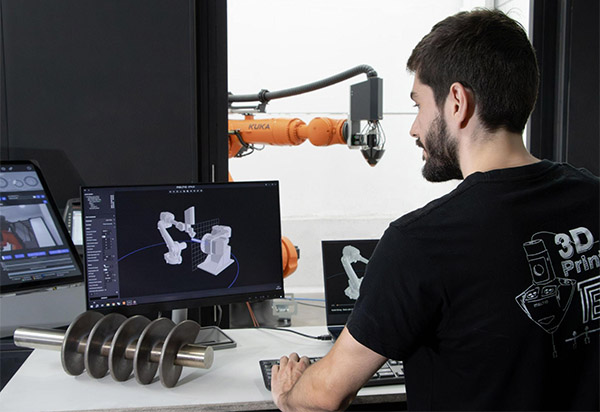

…described itself as a leader in wire-laser metal deposition additive manufacturing, today announced the Meltio Space software. The company said Meltio Space is a toolpath generator designed to accelerate adoption of its technology and help users benefit from robotic 3D printing without requiring expertise in robotics or programming. “Meltio Space makes it possible to design very reliable parts as quickly as possible and with a wider range of possibilities for our industrial customers,” stated Alejandro Nieto, Meltio Engine product manager. “This is thanks to a very user-friendly interface of the Meltio Engine Robot Integration.” “The learning curve of our Engine…

Found in Robotics News & Content, with a score of 24.89

…to show metalworking technologies with partners, as well as additive manufacturing offerings. “The conference agenda for FABTECH includes more than a dozen sessions related to workforce development, retention, or training,” stated Casey DiBattista, chief regional officer for North America at KUKA. “Taking an active role in robotics training and education fulfills our promise to be a single source in automation for our customers and partners.” FABTECH is North America's largest metal forming, fabrication, welding, and finishing event, according to organizer SME. KUKA will feature product demonstrations at Booth B27051 at McCormick Place in Chicago from Sept. 11 to 14. KUKA…

Found in Robotics News & Content, with a score of 17.55

…in technology are changing how business is done. The manufacturing industry in particular is becoming more efficient, as production, assembly, and supply chain operations add automation. Learn more about the increasing role of technology across manufacturing in the infographic below. Technology is affecting numerous areas of manufacturing through a broad range of methods, tools, and processes. They include: Remote monitoring and sensors Artificial intelligence Automation integration Digital twins Computerized maintenance management systems (CMMS) Additive manufacturing Areas of manufacturing benefiting from tech Here are some key areas where technology is rapidly increasing, expanding, and changing the face of the manufacturing industry.…

Found in Robotics News & Content, with a score of 11.51

…trio said they identified the need to scale up additive manufacturing (AM) processes for large-scale applications such as bespoke concrete formwork. “Currently, to develop a lightweight carbon-fiber element or to build a topologically optimized concrete floor slab, buyers would have to wait months and spend vast sums of money to receive a first sample and only then build a prototype, let alone consider reiterating for any flaws,” said SAEKI's founders in a release. “With SAEKI, this bottleneck is removed, enabling buyers to rapidly innovate and grow their services and offerings in ways they have not been able to before,” they…

Found in Robotics News & Content, with a score of 10.41

…the growing use of advanced technologies for eyewear marketing, manufacturing, and distribution. Specifically, industry applications of robotics and artificial intelligence can play a substantial role in boosting sales and the overall customer experience. This paints an optimistic picture for the global eyewear market in the coming years. Robots and automation modernize supply chains Robotics and automation have been instrumental in modernizing the supply chain, starting with design and manufacturing. For example, Materialise NV and Ditto have partnered to introduce 3D printing to the eyewear industry. With a focus on developing end-to-end platforms, this collaboration and others seek to use additive…

Found in Robotics News & Content, with a score of 14.15

…Robotics and its efforts to help customers enhance their “manufacturing resiliency.” In addition, Burd talked about Markforged's new 120,000 sq. ft. global headquarters in Waltham, Mass. The goal of the new facility is to unify the company's growing staff. The new headquarters features engineering labs and an “interactive product showroom” for visitors, according to Markforged. Editor's note: This interview has been edited and condensed for clarity. Can you describe your role at Markforged? Burd: I've been in the manufacturing industry for 15 years. For the past six years, I have been at Markforged, typically in the applications engineering space. I…

Found in Robotics News & Content, with a score of 23.79

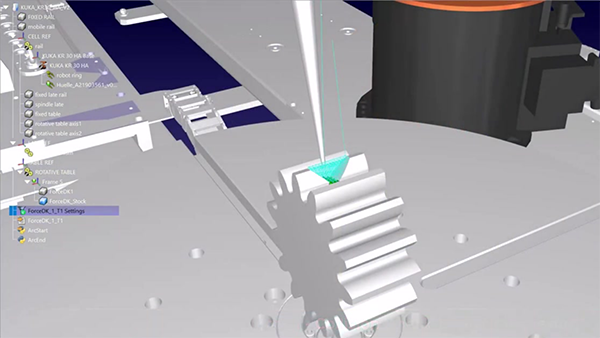

…a recent collaborative effort with FORCE Technology and Hexagon Manufacturing Intelligence using ESPRIT additive toolpath programming, an industrial robot was programmed using RoboDK’s simulation software. ESPRIT and RoboDK, a powerful combination of toolpath programming and robot digital twin with post-processing and analysis capabilities, were used to create the final part. The system included a 6-axis KUKA robot arm mounted on a rail (linear axis), a tilting table for rotary operation, and a spindle. Additionally, a GTV cladding head (powder+laser) enabled additive functions resulting in an overall cycle time of 5 minutes when reloading Steel 4140 parts. This project examined the…

Found in Robotics News & Content, with a score of 13.30

…completed a collaboration to evaluate the automation of crucial manufacturing operations using the global aerospace company’s industrial robots integrated with Xaba’s proprietary physics-informed deep artificial neural network model, xCognition. Xaba and Lockheed Martin identified a use case focused on a typical robotics work cell used in any aerospace factory to test how Xaba’s xCognition “synthetic brain” could empower a commercial robot with greater intelligence and understanding of its body and the task it is about to execute while ensuring required quality and tolerances are achieved. The test consisted of two phases: Phase 1: Assessing the robot’s performance in maintaining accurate…

Found in Robotics News & Content, with a score of 10.53

…Rolleri Robotic collaborative robots for easier welding operations in manufacturing. “We developed xCognition to provide a synthetic brain for commercial industrial robots and cobots used in a range of applications, from consumer and PCB assembly to industrial manufacturing for the automotive and aerospace sectors,” said Massimiliano Moruzzi, CEO of Xaba, in a press release. “Our goal is to make it easier and much more efficient for anyone to adopt robotics for assembly, welding, and drilling by significantly reducing the time required to calibrate, program, and supervise robots,” he added. “This partnership with Rolleri is an important step in enabling us…

Found in Robotics News & Content, with a score of 7.12

…added. “The current $20 million expansion of our U.S. manufacturing facility will allow us to serve the local market at a higher level, bringing us even closer to our customers as we provide them the technology, expertise, and support necessary to transform these challenges into resilient competitive advantages.” ABB Robotics & Discrete Automation is a unit of Zurich-based electrification and automation leader ABB Group. ABB Robotics to demo multiple systems at Automate ABB said highlights of its Automate booth will include demonstrations of its cobots, rebranded ABB AMRs (formerly from ASTI), and collaborative industrial robots, as well as relevant applications…