Editors’ Picks

Found in Robotics News & Content, with a score of 3.13

…system simulation software helps accelerate digital twin creation through ease of use and democratized access to system simulation, the company notes. By extending Modelica support and integration with other Simcenter solutions, Simcenter Amesim helps users to set up a toolchain throughout the development cycle. With the latest release, Siemens Digital Industries Software accelerates the Simcenter Amesim delivery model to provide access to new enhancements every 6 months. According to the company, the latest updates to Simcenter Amesim include: addressing vehicle electrification by importing Simcenter Motorsolve and Simcenter Battery Design Studio models; frontload aircraft systems performance engineering, thanks to upgraded CAD…

Found in Robotics News & Content, with a score of 3.10

…in developing and using mobile robots How to improve ease of use for workers on the factory or warehouse floor The types of data that managers need for efficiency and throughput The need to coordinate processes, robots, and people Robotics as a service (RaaS) and mobile robot fleets The need for interoperability among systems from multiple vendors and current standards efforts Register now for this Robotics 24/7 Roundtable, and submit questions now or ask them during the live broadcast. Speakers: Lior Elazary Co-founder and chief executive officer inVia Robotics Matt Fitzgerald Director of product management 6 River Systems Matt Charles…

Found in Robotics White Papers & Archives, with a score of 3.00

…Once that is complete, the AMRs are designed for ease of use by your operational team. No more training is needed than for any other new technology addition, and you do not need a team of robotics engineers on staff. 3. AMRs are too expensive When you look at an AMR it’s easy to jump to the conclusion that they are too expensive for the average warehouse. They seem like a futuristic technology decades in the making, and an investment that only top-tier warehouses can afford. In reality, many AMR solutions are affordable for any size warehouse. Many of the…

Found in Robotics News & Content, with a score of 2.96

…customers go farther with robotics. ABB designs GoFa for ease of use, safety, productivity ABB directed its product designers to create a cobot to encourage people, particularly first-time users, to confidently use and interact with robots. “Making robots more approachable, easier to use, and more intuitive is key to our vision to make robots as familiar in the workplace as a laptop is today,” stated Sami Atiya, president of ABB’s Robotics & Discrete Automation business. “I am delighted that our new cobot GoFa has been recognized by the Red Dot jury for how user-friendly it is.” “GoFa is a game-changer,…

Found in Robotics News & Content, with a score of 2.91

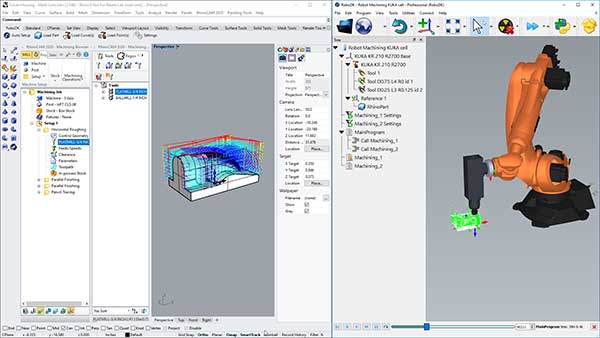

…robot control programs. RoboDK’s intuitive user interface and extensive support for various robots, coupled with the power, functionality, and ease of use of MecSoft’s milling products make this an outstanding product combination for milling using robots. Sources: Press materials received from the company and additional information gleaned from the company’s website.

Found in Robotics News & Content, with a score of 2.67

…factors when choosing a 3D printer. Costs, reliability and ease of use play important roles in decision-making. A whole 95% of respondents rated reliability as an important benefit, while 90% said ease of use was important and 89% said costs were important. “The importance of 3D printing in education cannot be overstated. The report revealed the shift from traditional learning environments to more interactive and engaging approaches. By teaching visualization, design and creation via 3D printing, 3D printing opens up opportunities for students and brings ideas to life,” adds Goshen. About the Study MakerBot surveyed over 1,000 education professionals who…

Found in Robotics News & Content, with a score of 2.44

Ease of use has been a mantra among robotics vendors in the past few years as they seek to expand adoption. Sensors and software have proven to be the “secret sauce” in automating new tasks. Realtime Robotics Inc. has developed proprietary motion-control technology to enable industrial robots to collaborate with human workers. Yesterday, the company announced completion of a $31.4 million Series A round. Realtime Robotics, which was founded in 2016, said it plans to use its funding to accelerate product rollouts. The Boston-based startup is a resident member of MassRobotics, an organization dedicated to growing the Massachusetts robotics ecosystem…

Found in Robotics News & Content, with a score of 2.43

…event were increased reach, vison-based guidance, and interfaces for ease of use. Vendors also touted cable management, new sensors, and greater payload capacities for arc welding and other industrial processes. “For 40 years, robotic arc welding evolved incrementally,” said Joe Campbell, senior manager of applications development and strategic marketing at Universal Robots. “Collaborative arc welding is the first disruptive technology to hit the robotic arc-welding market since the introduction of DC servo-powered robots.” He attributed the rapid market traction to several key drivers including a significant shortage of welders, increase in high-mix/low-volume production, and the fact that cobot welders are…

Found in Robotics News & Content, with a score of 2.36

…automation that combines industrial-grade robot welding functionality with consumer-level ease of use,” stated Rob Goldiez, co-founder and CEO of Hirebotics. Cobot Welder is designed to allow workers who are not robotics programmers to teach a collaborative robot new parts and welds. The smartphone app runs on Hirebotics' cloud-based Beacon platform for building and monitoring applications. Launched last year, Beacon is certified in the UR+ support ecosystem of cobot leader Universal Robots A/S. Hirebotics was founded in 2015 and collaborated in the development of the BotX cobot welding system. Odense, Denmark-based Universal Robots was founded in 2005 and is part of…

Found in Robotics News & Content, with a score of 2.31

…from them, we can look at cobot safety and ease of use in more detail. Our first post explained that collaborative robots are robot arms designed to work near humans in industrial settings. They are also designed so that workers who are not robotics experts can more easily program them. Cobot safety standards Cobot safety standards are governed by ISO/TS 15066. This standard is very deliberate in differentiating between a robot and a robot system. In simple terms, a robot is the industrial arm and its controller. While the robot arm itself can move around in a workspace, there is…

Found in Robotics News & Content, with a score of 2.28

…are not all the same in either performance or ease of use. Cobots can fill a wide range of roles, but the best cobot for teaching and educational purposes may not necessarily be the best cobot for an industrial process such as sanding or assembly. When selecting a cobot, the first question to answer is what are you trying to do with the cobot? The answer to that question will help determine what attributes are most important to you. Once you have answered this question, consider the following factors, evaluated with level of importance for your application, to narrow down…

Found in Robotics News & Content, with a score of 2.26

…they can help both novice and experienced robotics users. “Ease of use in robotics is more important than ever, and the new T-B Series SCARA models bring exceptional value without compromise to both new entrants and advanced manufacturers,” said Scott Marsic, group product manager at Epson Robots. “Epson strives to simplify automation for all users, and the new T3-B and T6-B are designed to provide uncomplicated solutions with productive outcomes.” “Paired with the no-code Epson RC+ Express software, users can add the robots to automation systems in no time,” he said. Building on a 35-year heritage, Epson Robots said it…