Hirebotics will demonstrate today how its new Hirebotics Cobot Welder, Powered by Beacon, can enable shops of all sizes to add automation. The Nashville, Tenn.-based company said its new system includes all the hardware and software needed to get started with robotics.

“The Cobot Welder is a major leap forward in easy-to-use welding automation that combines industrial-grade robot welding functionality with consumer-level ease of use,” stated Rob Goldiez, co-founder and CEO of Hirebotics.

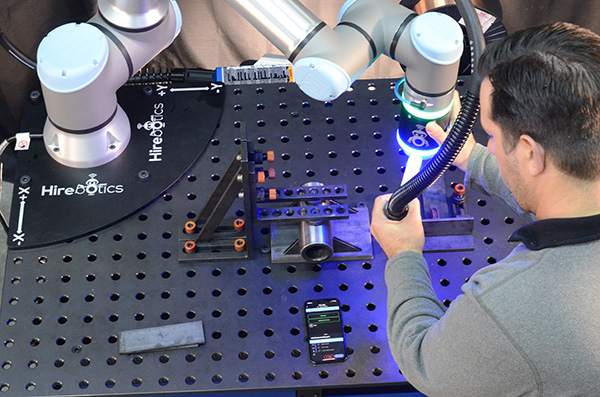

Cobot Welder is designed to allow workers who are not robotics programmers to teach a collaborative robot new parts and welds. The smartphone app runs on Hirebotics' cloud-based Beacon platform for building and monitoring applications. Launched last year, Beacon is certified in the UR+ support ecosystem of cobot leader Universal Robots A/S.

Hirebotics was founded in 2015 and collaborated in the development of the BotX cobot welding system. Odense, Denmark-based Universal Robots was founded in 2005 and is part of Teradyne Inc.

Cobot Welder addresses welder shortage

“The welding profession is experiencing a labor crisis,” said Joe Campbell, senior manager of applications development and strategic marketing for North America at Universal Robots. “The average age for skilled welders is 55. Most are likely to retire within 10 years, and younger people aren’t entering the profession in sufficient numbers to sustain industry demand.”

“There is an urgent need for collaborative welding systems that are safe to use around human beings and can be used to support expert human welders by taking over the tedious and unergonomic aspects of the welding process,” he said. “Hirebotics has simplified automation to the point that a good welder can set the robot in short order. This is great for high-mix, low-volume environments.”

“We're constantly trying to figure out how to make automation easier and more accessible to manufacturers,” Goldiez told Robotics 24/7. “We abstract it so that anyone on the shop floor can pick up their phone and teach new parts to weld. People can do lead-through teaching without having to take their hands off the robot to deal with the teach pendant.”

“Our learnings from BotX and Beacon helped us continue to drive down the time it takes someone to teach the robot,” he noted. “Often, one side of a piece is being loaded while the other is being welded, which is a good application for cobot welding.”

Playlists and reducing time to teach

“We also take the concept of playlists, using that same terminology for parts,” Goldiez explained. “You can just teach a part once, add it to a playlist, and hit go. The user can easily reorganize tasks in a playlist.”

“Hirebotics has pioneered the move from the pick-and-place world to process,” added Campbell. “If you have the proper tooling and fixturing and take the best welders to teach the right torch angles, it's a force multiplier in capability.”

“With Cobot Welder, Hirebotics has managed to eliminate the pain points from robot welding system deployments,” said Mitch Dupon, director of business development at Hirebotics. “At the heart of the system is our Cobot Welder smartphone app, which turns welders into robot programmers in a matter of minutes, no pendant required.”

“By reducing the time taken to teach new parts by as much 60%, Cobot Welder reduces downtime, improves welding quality and productivity, and ensures painless automated welding deployments,” he added. “I’m excited to talk about this and the other productivity benefits provided by Cobot Welder at the forthcoming launch.”

Hirebotics continues UR collaboration

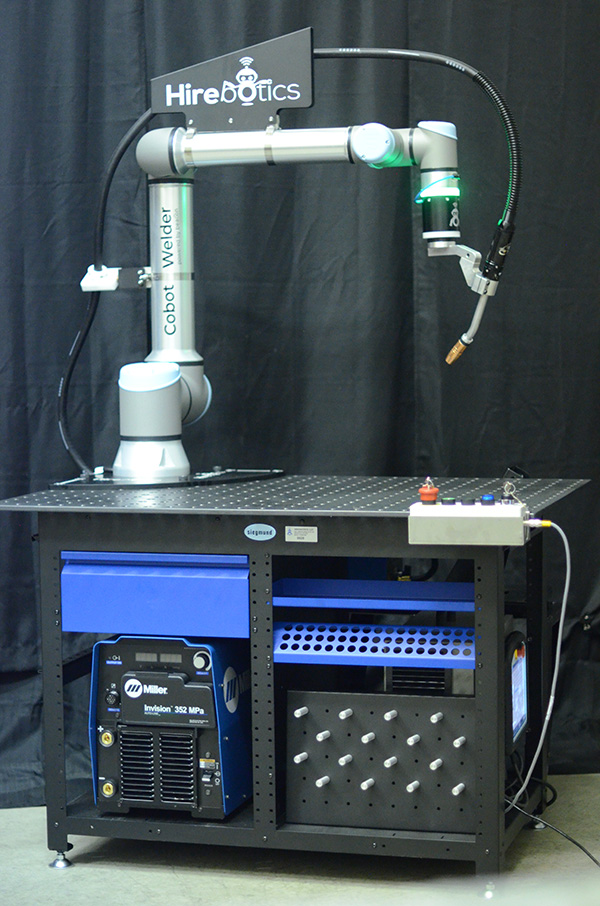

Cobot Welder includes a UR10e collaborative robot arm, a Miller Invision 352 MPa cobot package, a Tregaskiss robotic torch, a mobile cart with a standard 5/8-in. diameter on 2-in. center hole pattern, and Hirebotics’ Cobot Welder cloud-connected app.

“We've been working with Universal Robots since 2014, and it has been a great partner,” said Goldiez. “We already have Beacon as a foundational element, and it's connected to the cloud so anyone can get data and analytics worldwide. The Cobot Welder app sits on top of that.”

While BotX is available through a robotics-as-a-service (RaaS) rental model, Cobot Welder will be available for direct purchase starting in the U.S. and Canada, said Goldiez.

“We have transparent pricing: An integrated package is $72,000 delivered, with a $70,000 option if the customer already has a table,” he said. “There's a $3,600-per-year software subscription that unlocks the ability to teach and edit welds.”

What sorts of companies will use Cobot Welder? “We've heard from the market that a lot of folks want this,” Goldiez replied. “The size of customers runs the gamut. We build for the needs of large customers, so the product also meets the needs of smaller job shops.”

“A lot of small and midsize shops think that automation is way too expensive; you need specialists and time,” added Campbell. “Our job is to break those preconceptions. The problem of worker shortages is not going away. This is an ideal application for cobots. Since welding can take time, it's more a matter of people and precision than speed.”

Event details

The online launch will be from 2:00 to 3:00 p.m. ET on Wednesday, April 28, 2021. It will include a live demonstration of Cobot Welder and a question-and-answer session. Speakers will include Goldiez, Campbell, and Dupon.

Register here to participate.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up