Editors’ Picks

Found in Robotics News & Content, with a score of 5.51

…the company places on workforce development as North American reshoring accelerates,” it said. Festo Didactic and SICK partnered to create a curriculum and hardware package they said integrates into any robot platform. Source: Festo Festo Didactic will show new online learning portal—the Festo Learning Experience, or Festo LX. It focuses on the growing need for more individualized learning, said the company. Festo LX provides modular resources for technical training. These resources can be individually assembled into courses and entire learning paths. Varied formats, such as videos, animations, simulations, and text units can help participants remain engaged, said Festo Didactic. Existing…

Found in Robotics News & Content, with a score of 10.01

…show everyone what’s possible with automation today!” Labor shortages, reshoring aid adoption; inflation a possible deterrent Despite the state of the U.S. economy, labor shortages, led by the manufacturing industry, remain the key driver in the growth of automation, said A3. As a result, more manufacturers continue to turn to robotics, especially to handle the “dull, dirty and dangerous” tasks unattractive to human workers, it said. “In addition to labor shortages, we’re seeing many U.S. manufacturers bring more tasks back to North America as international labor costs continue to climb,” said Alex Shikany, vice president of membership and business intelligence…

Found in Robotics News & Content, with a score of 10.96

…days. Part of that demand is being driven by reshoring efforts. Customers have experienced firsthand the instability from relying too heavily on the global supply chain and are making efforts to bring production closer to home. Helfrich Brothers Boiler Works primarily designs and manufactures equipment for waste-to-energy facilities. It also develops systems that semiconductor companies use to make computer chips. Helfrich Brothers is based in Lawrence, Mass., and its staff works out of a 95,000-sq.-ft. steel fabrication and machine shop. “As manufacturing is coming back to the States, we're getting more orders than we can handle,” said Helfrich, a manufacturing…

Found in Robotics News & Content, with a score of 14.27

…time, the company is focusing on sustainability and embracing reshoring efforts. The company said it feels confident in its investment in the U.S. with the passage of Reduction Act, CHIPS Act, and Infrastructure and Investment in Jobs Act. U.S. Country Holding Officer of ABB Michael Gray said the Inflation Reduction Act has helped “trigger” new investments in clean energy and technology companies building locally. “More than ever before, ABB is designing and producing products domestically to serve our U.S. customers, as they move toward more sustainable electric power generation, clean energy manufacturing, electric transportation, and industrial efficiency including carbon capture…

Found in Robotics News & Content, with a score of 4.12

…scale. Tightness in access to skilled labor (13%) and reshoring of production back to North America (11%) were considered less impactful. Click on image to enlarge. Source: Vecna Robotics The robots are coming, says Vecna “Given this data, we can see that automation has quickly become a critical strategic priority, and from the boardroom to the warehouse, leaders are looking to get robots and other warehouse technologies on the floor as soon as possible,” said Vecna Robotics. The company said it expects the following trends this year, based on the survey data: High-speed, secure Internet is the biggest technology obstacle…

Found in Robotics News & Content, with a score of 5.80

…a long-term concern. A lot of manufacturing has been reshoring because of trade restrictions with China. We're expecting $1 trillion in business to come back to the U.S., which bodes well for 3PLs and service providers here. The real challenge is continued low vacancy rates in most major markets around the U.S. We're finalizing a facility in Portland with sub-3% vacancy. If you look at the Inland Empire [in Southeastern California], there's no space at all. Businesses have been waiting in line for months for a building to come up, and then they're paying insane amounts. Wagner is looking at…

Found in Robotics News & Content, with a score of 6.67

…mega trends of labor shortages, uncertainty, the near- and reshoring of production, and a desire to operate more sustainably accelerate, more businesses are turning to automation to build resilience while improving efficiency and flexibility,” he added. “Our expanded facility will help us to better serve customers in the U.S. and across the Americas, giving them access to innovative automated solutions.” ABB to automate its own production ABB said it plans to use the latest technologies to make its next-generation robotics, streamlining the delivery process and reducing lead times. The plant will use flexible, modular production cells that are networked and…

Found in Robotics News & Content, with a score of 6.86

…feasible where it once seemed impossible.” As manufacturers consider reshoring production to Europe or North America, Fuzzy Studio offers “an easy and low-risk solution for investment,” asserted Fuzzy Logic. The software is compatible with most robot brands on the market, the company noted. Fuzzy Studio enables interactive digital twins Today, the creation of robotic cells is often complex, said Fuzzy Logic. The company said Fuzzy Studio simplifies that process. The software comes in two licenses on the Fuzzy Logic website. The Fuzzy Studio Simulation license allows non-robotics users to create and preview a robotic cell in a simulated environment, while…

Found in Robotics News & Content, with a score of 14.91

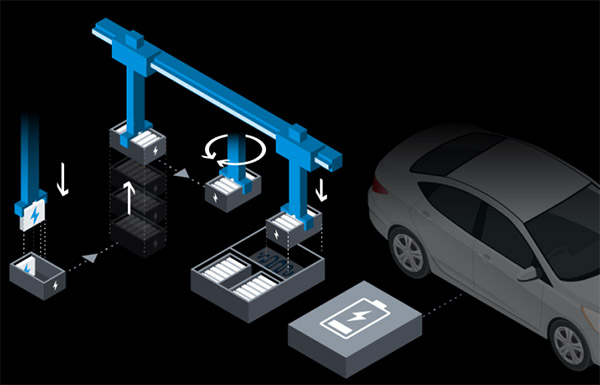

…sensors are likely to become industry-standard for robotics. 2. Reshoring Resilience has become an important driver for reshoring in various industries. For instance, car manufacturers invest heavily in short supply lines to bring processes closer to their customers. These automakers use robots to produce powerful batteries cost-effectively and in large quantities to support their electric vehicle projects. These investments make the shipment of heavy batteries redundant. This is important as more and more logistics companies refuse to ship batteries for safety reasons. Relocating microchip production back to the U.S. and Europe is another reshoring trend. Since most industrial products nowadays…

Found in Robotics News & Content, with a score of 7.69

…challenges are some key factors driving automation, he explained. Reshoring starts at the top Nolan said Massachusetts is following the lead of the federal government and its efforts to bring more manufacturing back to the states. Based out of Westborough, Mass., the Massachusetts Technology Collaborative is a state agency that provides funding and support to a variety of different industries. The Center for Advanced Manufacturing is a division of the collaborative and is charged with helping support local manufacturers to boost the state economy. “It [has] a lot to do with robotics and automation,” Nolan said. “Because we know if…

Found in Robotics News & Content, with a score of 6.57

…fill the millions of open positions in manufacturing. Would reshoring of production to the U.S. help or worsen that situation? Martinelli: It's complicated. Supply chains could shorten, which is nice, but there's still a need for manufacturing talent in the U.S. Another challenge is that nobody really wants to stand at an ASRS. They'll start to feel more like consumer products for what Gartner called the “gaming generation.” What are some of the human-centric aspects of working with automation? Martinelli: It's not just a short-term problem of labor shortages, bussing workers longer and longer distances, or wages not being sustainable.…

Found in Robotics News & Content, with a score of 10.46

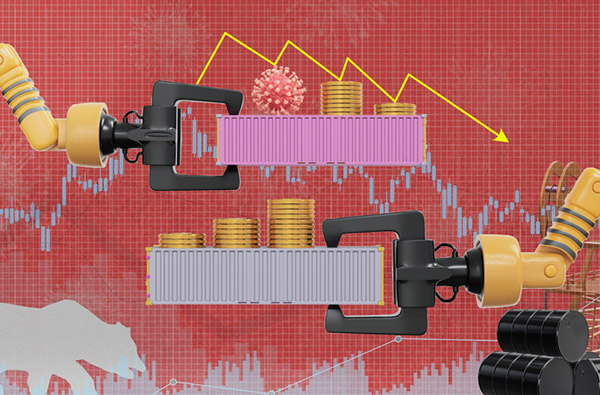

…from the stress of the pandemic, operators have begun reshoring and using automation to offset higher U.S. labor costs. Businesses are also dealing with a perceived low status of “frontline” jobs, reduced immigration, and more retirements with lower replacement rates. Major industries will continue to invest in robotics Whether or not the U.S. economy shrinks in 2023 or 2024, we should see much of the same occurring across industries like construction, manufacturing, and logistics. Manufacturing: The use of industrial robots in factories is quickly accelerating. There are over 4 million industrial robots, or about 126 robots per 10,000 employees, which…