Editors’ Picks

Found in Robotics News & Content, with a score of 11.28

…says. “Companies are definitely accelerating implementation plans.” Session 6: Reshoring Global strategy: The pros and cons of reshoring High transportation costs, supply chain interruptions, and global trade wars are all pushing companies to reexamine their global manufacturing and sourcing strategies. Some of them are bringing their operations back to the U.S. through a process known as “reshoring.” This session finds Rosemary Coates, executive director of the Reshoring Institute, walking attendees through the offshoring timeline and showing why reshoring may be a good choice for organizations now and in the aftermath of the global pandemic. “In the 1990s and 2000s, offshoring…

Found in Robotics News & Content, with a score of 11.20

…material costs, in addition to the growing trend of reshoring and nearshoring of operations, means more companies are adopting robotic automation to maximize flexibility, build resilience and adapt more sustainable production processes.” Trend 1: Demand for robots will increase in response to labor shortages and reshoring/nearshoring surge The impact of labor shortages is clearly felt across a wide range of industries and will continue well beyond 2023 as the effect of aging populations and a reluctance to take on low paid, dull, dirty and dangerous jobs increases. The Congressional Budget Office recently forecast that the size of the U.S. labor…

Found in Robotics News & Content, with a score of 11.10

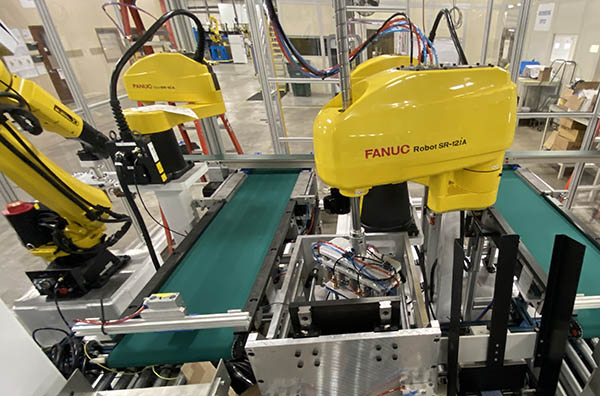

…have led to more robotics use. “According to the Reshoring Institute, reshoring of production is at record highs due to supply chain issues,” Burnstein said. “While we don't yet know the impact of inflation on robotics orders, I keep hearing—it doesn't matter the industry: warehousing or manufacturing—labor shortages are the primary driver of automation right now. Everyone needs robots to keep up production to meet demand.” Most industrial robots are made in Asia or Europe, but they are sold through U.S.-based subsidiaries, noted Burnstein. “However, much of the integration services, software, AI, and vision systems come from U.S. suppliers,” he…

Found in Robotics News & Content, with a score of 10.96

…days. Part of that demand is being driven by reshoring efforts. Customers have experienced firsthand the instability from relying too heavily on the global supply chain and are making efforts to bring production closer to home. Helfrich Brothers Boiler Works primarily designs and manufactures equipment for waste-to-energy facilities. It also develops systems that semiconductor companies use to make computer chips. Helfrich Brothers is based in Lawrence, Mass., and its staff works out of a 95,000-sq.-ft. steel fabrication and machine shop. “As manufacturing is coming back to the States, we're getting more orders than we can handle,” said Helfrich, a manufacturing…

Found in Robotics News & Content, with a score of 10.66

…cobot providers, but he did say that he expects reshoring of production and growing awareness by small and midsize enterprises (SMEs) to help sales. “Reshoring is happening slowly because manufacturers can't just rip out their supply chains, and global companies need to protect themselves and can't locate in just one country,” he said. “Also, there's a lot of innovation continuing in this space.” Users top of mind To help businesses implement automation, many vendors have touted their latest products' ease of use. At the same time, newcomers should still seek the best information and assistance as they evaluate tasks and…

Found in Robotics News & Content, with a score of 10.46

…from the stress of the pandemic, operators have begun reshoring and using automation to offset higher U.S. labor costs. Businesses are also dealing with a perceived low status of “frontline” jobs, reduced immigration, and more retirements with lower replacement rates. Major industries will continue to invest in robotics Whether or not the U.S. economy shrinks in 2023 or 2024, we should see much of the same occurring across industries like construction, manufacturing, and logistics. Manufacturing: The use of industrial robots in factories is quickly accelerating. There are over 4 million industrial robots, or about 126 robots per 10,000 employees, which…

Found in Robotics News & Content, with a score of 10.35

…increase overall productivity and accelerate the trend towards further reshoring of US manufacturing. It also creates better jobs and attract younger generations to the industry,” Peters said. Robotics group aims to remove barriers to robot adoption While most manufacturers have acknowledged the need for automation, mainstream adoption is still slow. Both Gain & Co and HowToRobot said they are changing that by removing some of the most common barriers to further robot adoption. “Lack of knowledge is what is currently keeping most manufacturers away from bringing in robot technology and automating,” said Peters. “Being 100% vendor-independent and not directly selling…

Found in Robotics News & Content, with a score of 10.29

…here for larger version. Source: Machina Labs RaaS and reshoring Machina Labs said it can supporting rapid deployment and scale up with no upfront investments in tooling. It also enables the remanufacturing of parts and components that are no longer in production and for which machinery or dies are no longer available. A robotics-as-a-service (RaaS) model replaces capital expenditure costs while preserving and creating jobs, said the company. In addition, Machina Labs said it can help businesses overcome supply chain problems by bringing production to the U.S. According to the U.S. Census Bureau, manufacturing has experienced a 60% increase in…

Found in Robotics News & Content, with a score of 10.01

…show everyone what’s possible with automation today!” Labor shortages, reshoring aid adoption; inflation a possible deterrent Despite the state of the U.S. economy, labor shortages, led by the manufacturing industry, remain the key driver in the growth of automation, said A3. As a result, more manufacturers continue to turn to robotics, especially to handle the “dull, dirty and dangerous” tasks unattractive to human workers, it said. “In addition to labor shortages, we’re seeing many U.S. manufacturers bring more tasks back to North America as international labor costs continue to climb,” said Alex Shikany, vice president of membership and business intelligence…

Found in Robotics News & Content, with a score of 9.81

…to other industries.” Other industries to benefit from cobots, reshoring “Healthcare, pharmaceuticals, and e-commerce demand went up because consumers couldn't go out like normal [during the COVID-19 pandemic], said Finazzo. “We're seeing new customer activity at record highs.” “In addition, collaborative robots subsidize labor rather than replace it,” he said. “You can take one skilled person, add three robots, and still come out ahead. When cobots came out, there were a lot of false starts around safety, which depends on the end-of-arm [tooling and payloads]. But their ease of programming has been tremendous for processes like welding and assembly, where…

Found in Robotics News & Content, with a score of 9.44

…firm Kearney recently shared findings from its 2021 index reshoring report and found that the trend will likely continue for the next few years. “Seventy-nine percent of executives surveyed who have manufacturing operations in China have either already moved part of their operations to the U.S. or plans to do in the next three years, and another 15% are evaluating similar moves,” the report noted. Agarwal said he believes part of it has to do with U.S government incentives and grants. Another big reason is that automation is driving costs down and allowing companies to bring operations closer to home,…

Found in Robotics News & Content, with a score of 9.17

…U.S. Bureau of Labor Statistics. An increasing trend towards reshoring tasks in North America is another contributing factor, said A3. “Record attendance at trade shows such as Automate in Detroit this year show even greater interest in robotics and automation than ever before, but as these numbers show, not all are ready or able to pull the trigger just yet,” said Jeff Burnstein, president of A3. “When the economy improves, however, the companies who have learned about the latest innovations in automation and how they can help them increase productivity, deal with labor shortages and get to market faster will…