Editors’ Picks

Found in Robotics News & Content, with a score of 9.87

…of tasks that have previously been manual, such as sanding, polishing, palletizing, and delicate assembly, said the partners. “Merging Flexiv’s robotic expertise with Cardinal’s extensive experience will deliver customers unmatched automation solutions while increasing the productivity, efficiency, flexibility, and competitiveness of businesses within the Great Lake State,” Flexiv said. Dajun Tao, an application engineer at Flexiv (left), meets the Cardinal Machine team. Source: Business Wire Cardinal Machine to integrate Rizon, Moonlight robots “We are excited and look forward to a successful, long-term partnership with Flexiv,” said Brian Pennington, president of Cardinal Machine. “Having Flexiv’s adaptive force-control technology available to us…

Found in Robotics News & Content, with a score of 36.38

…launch of GRIT, its first collaborative robot for composites sanding. Developed by aeronautics and composite experts, GRIT can improve productivity, reduce health risks, and solve labor shortages for aerospace maintenance, repair, and overhaul, or MRO, companies, claimed the Chino, Calif.-based company. “Aerospace and defense manufacturers require extremely precise sanding, grinding, polishing, and finishing work to ensure parts meet regulatory requirements and achieve top performance,” stated Alan Hiken, chief operating officer at Kane Robotics and a composites expert with a 30-year career in aerospace engineering. “GRIT cobot solutions provide the highest-quality work and help save teams from injuries and illness by…

Found in Robotics News & Content, with a score of 29.18

…robotic system used for sandblasting, thermal spraying, shot peening, sanding, polishing, and welding applications at the show at Hall 11 Stand A45. The company said it is attending the show to help expand its presence in the European market and better demonstrate its simplified robot programing solutions. Augmentus claimed to serve a diverse customer base across various industries, such as aerospace, automotive, maritime, and supply chain. Its systems are used by companies such as ST Engineering, Hyundai, Abrasive Engineering, Johnson & Johnson, and Fujitsu. Augmentus aims to make automation simpler The company was established in 2019 and claims to be…

Found in Robotics News & Content, with a score of 6.91

…to allow for the handling of delicate objects for sanding and polishing. The robot can be installed at any angle, the company said. Kawasaki Robotics shows automated bin picking At IME West, Kawasaki Robotics displayed two robots. The MC004V, guided by Apera AI’s Vue robotic vision software, demonstrated a random bin-picking application of clear test tubes. Kawasaki said this capability could be useful for pharmaceutical and medical device manufacturing, as well as consumer packaged goods (CPG), injection molding, and plastics. The robot arm meets the healthcare industry’s strict guidelines for accuracy, consistency, and cleanliness, according to Kawasaki. It also has…

Found in Robotics News & Content, with a score of 9.27

…of a part for deburring or its surface for sanding and grinding, the possibilities are available to all, said the company. Users can add an unlimited number of waypoints to these trajectories, it said. “This functionality offers order of magnitude time savings to users, as the generation of trajectories frees them from dependence on robotic experts,” said Fuzzy Logic. With Fuzzy Studio, the basic specifications of a project can be validated in just a few minutes instead of several weeks, and at a lower cost. Information on the sizing of the robotic cell is displayed for easy decision-making before moving…

Found in Robotics News & Content, with a score of 13.84

…the robot could be used for screw fastening, loading, sanding, and polishing. The company also develops robot arms through its Rizon series. Robots in that line include the Rizon 4, the Rizon 4s, and the Rizon 10. “Moonlight is a combination of our award-winning Rizon series of robots and the industry-proven parallel bot design,” stated Hao Jiang, director of product development for Flexiv. The company added that the robot can complete many of the tasks a robot arm can do but with the speed and agility of a parallel robot. “We saw that in some specific applications, customers needed a…

Found in Robotics News & Content, with a score of 10.51

…Kane Robotics will show the GRIT ST-X system for sanding, grinding, and finishing, using ATI’s UR+ certified Compliant Reciprocating Tool. Universal Robots to show off UR20 at FABTECH For the first time at a fabrication show in North America, attendees will be able to see the UR20 cobot, which has 20 kg (44 lb.) payload. Universal Robots said it can reach further into machines, tend several machines in the same cycle, and handle 25% heavier parts than other UR cobot models. Despite being the company’s most powerful robot arm, the UR20 is the lightest cobot in its class, weighing only…

Found in Robotics News & Content, with a score of 29.55

…and defense industries involve combustible, dangerous dust created by sanding. The invention of a force-compliant C2D1-rated automated sander, with integral dust collection, virtually eliminates the risk of exposure and occupationally acquired respiratory infections, said Aerobotix and FerRobotics. “Aerobotix remains committed to improving safety in the aerospace and defense industries,” said Josh Tuttle, business development manager at Aerobotix. “As such, we’re proud to partner with FerRobotics on this important tool to help save lives and reduce lung disease in the workplace.” Huntsville, Alabama-based Aerobotix specializes in the creation of automation for the production of high-value, high-precision components, aircraft, and vehicles. The…

Found in Robotics News & Content, with a score of 7.82

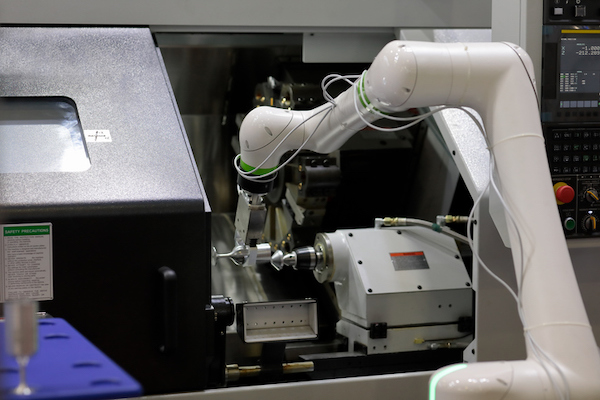

…a welder, a palletizing robot becomes a palletizer, a sanding robot becomes a sander, and so on, working with the respective OEMs in each case. For example, a robot vendor would work directly with a CNC equipment manufacturer to define and develop a custom configuration. This would include the number of degrees of freedom, the payload, reach, mechanical interface, communications, software, etc. Delivering a functional system that is integrated “out of the box” not only automates the machine-tending task, but it also improves total productivity, which is what the end user ultimately values. For reference, the global CNC market was…

Found in Robotics News & Content, with a score of 9.10

…ARM Institute. “Projects have ranged from robots for sewing, sanding and grinding metals, and sorting fish to PCR testing for COVID-19.” “We typically see three types of project teams,” he told Robotics 24/7 during a recent visit to ARM's headquarters in Pittsburgh. “There are the standard vertical teams, involving robotics vendors. Then there are the horizontal ones, such as aerospace manufacturers working on wire harnesses. Finally, there are the non-standard, pre-competitive ones, such as small startups or groups within universities and larger companies.” ARM project call includes new features The ARM Institute's latest project call is different from its predecessors,…

Found in Robotics News & Content, with a score of 16.27

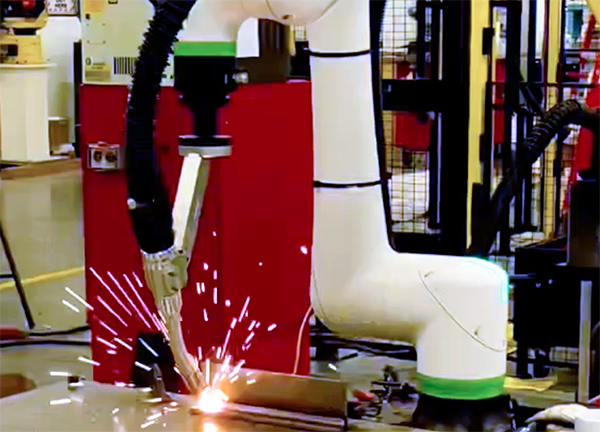

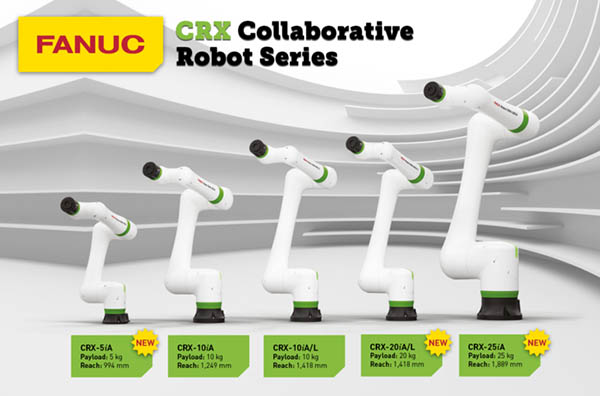

…the CX1000 can be uncoupled from the weld cart and repurposed for different applications such as machine tending or sanding when not welding. The FastARC CX1000 cobot is equipped with a FANUC six-axis, 10-kg (22 lb.)-capacity cobot arm that Acieta said is maintenance-free for up to eight years. The system is compatible with Lincoln Electric and Miller Electric welders and is IP 67-rated with sealed components to work in industrial environments.

Found in Robotics News & Content, with a score of 13.56

…loading and unloading, packing, palletizing, vision-guided pick and place, sanding, and welding. The CRX robots can detect external forces in the workspace, stopping safely when making contact with a person or object. This technology allows the cobots to work safely alongside people without the need for expensive guarding. FANUC said its new CRX-5iA, CRX-20iA/L and CRX-25iA collaborative robots can handle payloads of 5, 20, and 25 kg (11, 44, and 55.1 lb.), respectively. They join its existing CRX-10iA and CRX-10iA/L models, which have 10 kg (22 lb.) payload and a reach of 1,249 and 1,418 mm (49.1 and 16.4 in.),…