Editors’ Picks

Found in Robotics News & Content, with a score of 17.71

…without additional sensors. An example of this would be sanding a thin composite part. In this application, it is important to control how much force is applied to avoid removing too much material and damaging the composite layers. Force-controlled robots not only offer safety, but are also useful for applications such as sanding. Source: SwRI Another example might be assembly of parts with threaded fasteners. Traditionally, this task would require precise indexing. However, with force control, the fastener position can be adjusted until it easily threads on. It is possible to get force control packages for traditional robots, but these…

Found in Robotics News & Content, with a score of 16.89

…the data can be used for process verification.” The tool is compatible with grinding media such as flap wheels, sanding discs and wire brushes, the company added. The CGV-900 is the latest end-of-arm tool to come out of the Novanta-owned company. The company also produces robotic tool changers, multi-axis force/torque sensing systems and material removal tools. For more information on the CGV-900, check out the company's product page.

Found in Robotics News & Content, with a score of 16.79

…can know how much force is being applied for sanding, material removal, or polishing, as well as the consumables used. This data gives us an edge over the competition.” Another feature of the system is that it can inform an operator whether the compensation device is in the 0 to 20 stroke range with a colored LED strip. “This is especially useful in automotive, where an operator walking by can see green if the tool is good or white if it needs attention,” Martinez said. “The EFC-02 can increase quality because its information page lets you observe the running time,…

Found in Robotics News & Content, with a score of 16.27

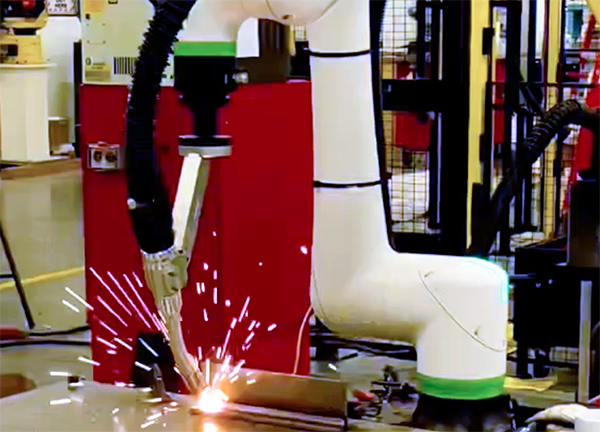

…the CX1000 can be uncoupled from the weld cart and repurposed for different applications such as machine tending or sanding when not welding. The FastARC CX1000 cobot is equipped with a FANUC six-axis, 10-kg (22 lb.)-capacity cobot arm that Acieta said is maintenance-free for up to eight years. The system is compatible with Lincoln Electric and Miller Electric welders and is IP 67-rated with sealed components to work in industrial environments.

Found in Robotics News & Content, with a score of 14.39

…can be configured for aerospace and defense applications including sanding, painting, and inspection. The demonstration robot will perform automated tasks on aerospace components. The global market for collaborative mobile robots could expand from $543.3 million in 2019 at a compound annual growth rate (CAGR) of 26.3% by 2030, projected Prescient & Strategic Intelligence. It cited growing demand for industrial automation, the automotive industry's adoption of mobile cobots, and increasing robot payload capacity to serve manufacturers. Want to learn more about data management in robots? This article was featured in the September 2024 Robotics 24/7 Special Focus Issue titled “Robots as…

Found in Robotics News & Content, with a score of 14.02

…& co-founder of Bota Systems. “Additional applications include large-scale sanding and polishing, precision mechanical assembly, and face matching/alignment of heavy workpieces, such as in CNC loader operations.” The SensONE T80 can handle up to 80 Nm of torque. Its peak-to-peak noise (measured at six times the standard deviation) is 0.3 N for force measurements and 0.012 Nm for torque, achieving the same precision levels as sensors used for lower payload cobots. Its torque range supports the full payload capacities for cobots exceeding 20 kg and 30 kg including also the expanded payload of 25 kg and 35 kg that was…

Found in Robotics News & Content, with a score of 13.84

…the robot could be used for screw fastening, loading, sanding, and polishing. The company also develops robot arms through its Rizon series. Robots in that line include the Rizon 4, the Rizon 4s, and the Rizon 10. “Moonlight is a combination of our award-winning Rizon series of robots and the industry-proven parallel bot design,” stated Hao Jiang, director of product development for Flexiv. The company added that the robot can complete many of the tasks a robot arm can do but with the speed and agility of a parallel robot. “We saw that in some specific applications, customers needed a…

Found in Robotics News & Content, with a score of 13.56

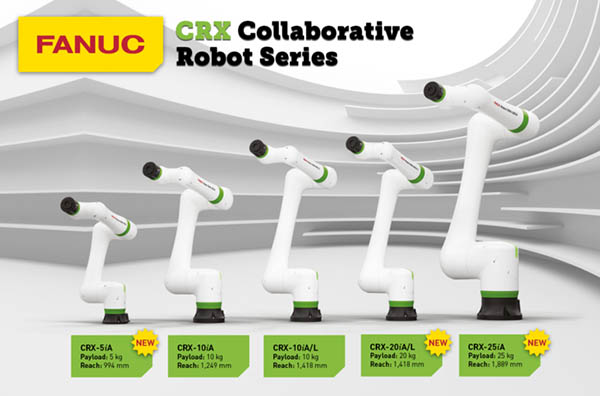

…loading and unloading, packing, palletizing, vision-guided pick and place, sanding, and welding. The CRX robots can detect external forces in the workspace, stopping safely when making contact with a person or object. This technology allows the cobots to work safely alongside people without the need for expensive guarding. FANUC said its new CRX-5iA, CRX-20iA/L and CRX-25iA collaborative robots can handle payloads of 5, 20, and 25 kg (11, 44, and 55.1 lb.), respectively. They join its existing CRX-10iA and CRX-10iA/L models, which have 10 kg (22 lb.) payload and a reach of 1,249 and 1,418 mm (49.1 and 16.4 in.),…

Found in Robotics News & Content, with a score of 12.76

…in a timely and cost-effective manner. Uniform Work Robotic Sanding with Intra-stage Inspection Lead: GKN Aerospace Partners: National Institute of Aerospace Research, GrayMatter Robotics, University of Washington, EWI Description: Past ARM Institute projects on automated surface-finishing worked on path-planning, uniform finishing, and automated inspection. The project team will combine the outputs from these past projects to create an effective sanding and polishing technology that benefits multiple industries. High-Precision Adaptive Machining for High-Temperature Materials Lead: GE Research Partners: GrayMatter Robotics, FANUC Description: The project team will focus on enabling high-precision adaptive machining of complex cooling circuits in high temperature materials through…

Found in Robotics News & Content, with a score of 12.08

…range of automation. It will include collaborative robots handling sanding and polishing and vision-guided robotic arms using deep learning algorithms to pick up items, as well as applications for automated machine loading, laser marking, and more. Manufacturers start to benefit from automation Scott Paulk, an engineering manager with Alexandria Industries in Dallas, said he is excited to attend Waves of Innovation. “Knowing what’s out there makes our automation journey easier,” he said, adding that his company has already automated has 40% of its work centers. “We sometimes struggle with hiring skilled labor; automation helps offset this by enabling us to…

Found in Robotics News & Content, with a score of 10.92

…industrial robots for applications such as welding, warehousing, gluing, sanding, and assembly,” explained Reger. “However, this volume only describes the minimum delivery volume over the next five years. The actual demand of our customers is much higher, but currently still limited by our production capacities.” “For a better classification of the demand as a whole—the order volume mentioned results from just one-time 14 contracts,” he noted. “We currently have around 100 more contracts under negotiation. That is why the new capital is so important, because we need to expand our production capacities very quickly.” NEURA is developing industrial robots that…

Found in Robotics News & Content, with a score of 10.51

…Kane Robotics will show the GRIT ST-X system for sanding, grinding, and finishing, using ATI’s UR+ certified Compliant Reciprocating Tool. Universal Robots to show off UR20 at FABTECH For the first time at a fabrication show in North America, attendees will be able to see the UR20 cobot, which has 20 kg (44 lb.) payload. Universal Robots said it can reach further into machines, tend several machines in the same cycle, and handle 25% heavier parts than other UR cobot models. Despite being the company’s most powerful robot arm, the UR20 is the lightest cobot in its class, weighing only…