Editors’ Picks

Found in Robotics News & Content, with a score of 23.78

…for a wide variety of tasks including materials handling, machine tending, polishing, and assembly and testing.” “[It] can now help more businesses achieve new standards of speed and accuracy as they develop solutions to lift and handle heavy, complex or irregular shapes, even in small workspaces,” he said. IRB 1300 designed for tight spaces Featuring a footprint of just 220 by 220 mm (8.6 x 8.6 in. or 73.9 sq. in.), the IRB 1300 is suitable for use in confined spaces, enabling more robots to be deployed in a specific area if required, said ABB. It is available in three…

Found in Robotics News & Content, with a score of 38.85

Automation for unstructured picking and placing of parts into machines typically relies on computer vision, which often requires additional programming, according to Universal Robots ApS. This is necessary to bridge the gap from “pick” to “place” – especially if the “place” is not just dropping items into a box but accurately inserting parts into fixtures for further processing, said the company. ActiNav combines real-time autonomous motion control, collaborative robots, vision, and sensor systems in one Application Kit to solve the random bin-picking challenge, claimed Universal Robots. To help manufacturers integrate ActiNav into machining cells, the Odense, Denmark-based cobot maker yesterday…

Found in Robotics News & Content, with a score of 50.61

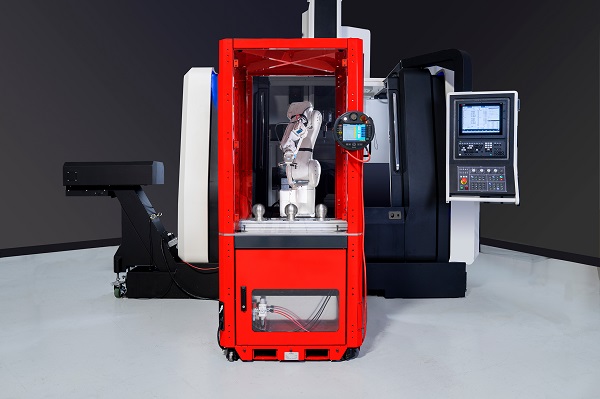

…that face labor shortages for CNC (computer numerical control) machine applications can benefit from the LoadMate Plus, said Mitsubishi Electric. The robot cell can provide flexibility for traditionally high-mix, low-volume facilities to introduce automation, according to the company. LoadMate Plus automates the task of loading and removing parts from a machine tool through the use of robotics. It can be mounted next to one machine or between two machines and otherwise moved around a facility as jobs require. When this cell is paired with Mitsubishi Electric M8 Series CNC, operators can use the Direct Robot Control (DRC) feature within the…

Found in Robotics News & Content, with a score of 18.12

…autononomous mobile robot (AMR) is suitable for tasks including machine tending, quality assurance sampling, and packaging in manufacturing and logistics applications. “The combination of our omnidirectional Vector and the OB7, which provides seven axes for precise grasping, makes this system the most capable mobile manipulator available today,” said Jason Walker, co-founder and CEO of Waypoint Robotics. “In addition, setting it up requires no programming, and either robot can be the primary controller for an operation.” Waypoint's Vector includes precise positioning “We could have had a moble manipulator a while ago, but some things were missing that we felt we could…

Found in Robotics News & Content, with a score of 21.63

…“There were many problems to solve, such as in machine tending, where a cobot doesn't know exactly where things are. Then there were the machine vision challenges, such as with lighting. Figuring out where to put a camera takes a bit of engineering before you start training.” “Any time you're dealing with variance in machine position, color, or place, the user can train MIRAI to understand what images mean and how to behave,” Vuine said. “Just connect camera to the robot's wrist and guide the arm to points. It watches and generalizes what it has been shown and knows where…

Found in Robotics News & Content, with a score of 28.65

…now have the ability to control connected robots providing machine tending or other assistance through FANUC’s Quick and Simple Startup of Robotization (QSSR). More manufacturers are adding robots to execute repetitive tasks previously performed manually, noted FANUC America. Advanced automation offers shops of all sizes a competitive edge and greater profit margins, according to the company. FANUC’s QSSR is a package intended to simplifies the connection of a FANUC robot to a FANUC controlled machine tool. The new QSSR G-code feature allows operators and machine tool builders to program robots easily through the FANUC CNC in ISO standard G-code format.…

Found in Robotics News & Content, with a score of 16.85

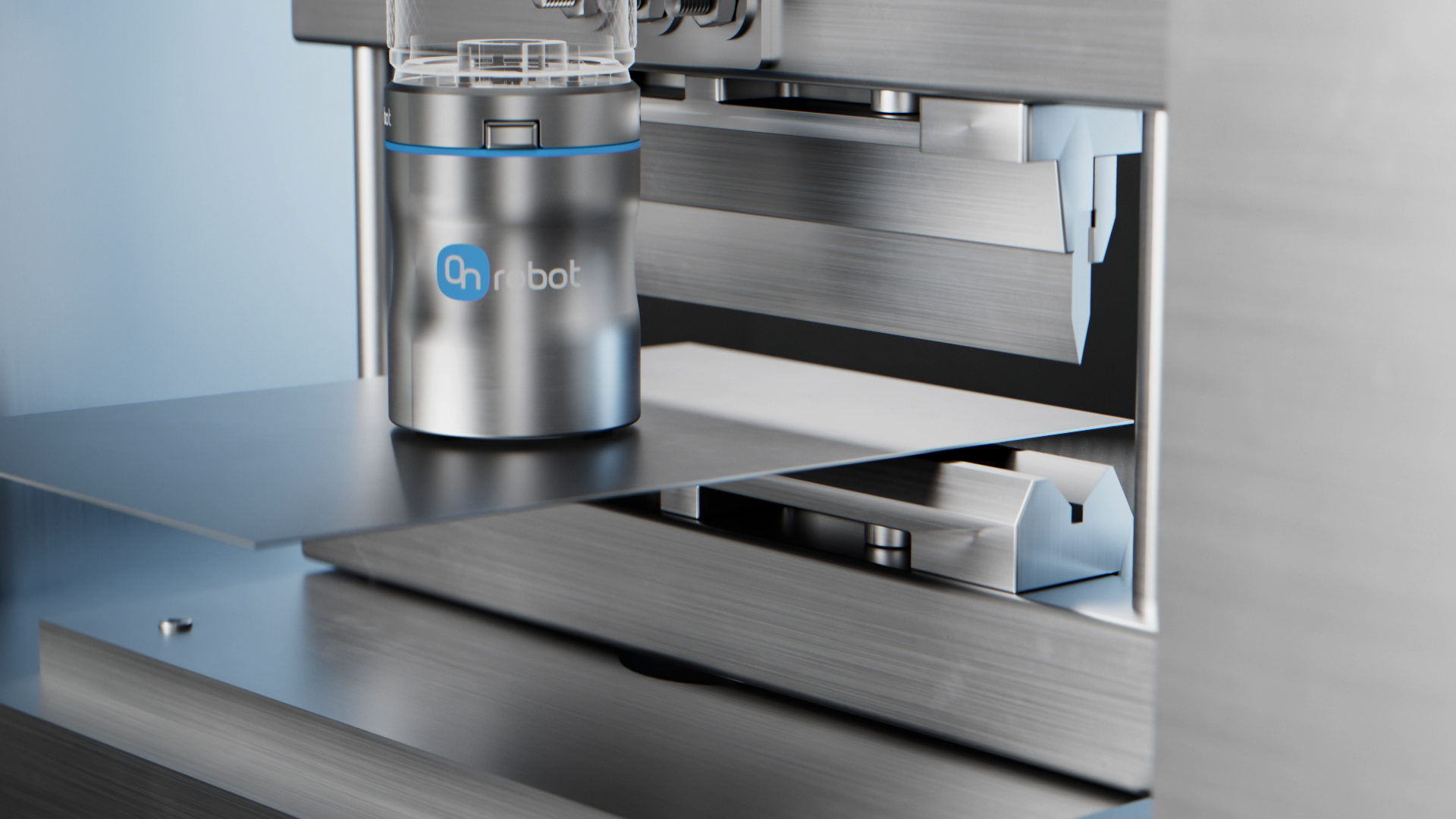

…the MG10 is designed for materials handling, assembly, and machine-tending applications in manufacturing, automotive, and aerospace applications. “Standard magnetic grippers only provide simple on/off functionality,” stated OnRobot. “To adjust the force applied, users have to add rubber ‘feet’ to create space between the magnet and the part. This is a tedious and imprecise process that doesn’t always guarantee perfect results, especially on applications that involve handling thin metal sheets and small metal parts where magnetic grippers often accidentally end up picking more than one sheet or part as the force cannot be adjusted.” The MG10's built-in sensing capabilities ensure smooth…

Found in Robotics News & Content, with a score of 31.50

…uses that can be seen include the OB7 CNC machine tending on a mill, an application enabled by Productive Robotics’ OB7 CNC Package. The package comes equipped with a 7-axis collaborative robot arm as well as all the necessary accessories needed to connect to any type of CNC mill, lathe, or other CNC machine. Another application being shown is OB7’s standard 5 kg model loading and unloading parts in and out of a milling machine. The largest model of the 7-axis cobot line, OB7-Max 12, can be used to palletize boxes. With a 12-kg payload capacity and a 1.3-meter reach,…

Found in Robotics News & Content, with a score of 17.54

…exhibits comprise the latest technologies and innovations in robotics, machine vision, motion control, artificial intelligence (AI) and related automation technologies. Welding, assembly and machine tending robots, mobile robots and human-robot collaborative technologies with intuitive user interfaces and software advances, machine learning and advanced computer vision technologies are just a few of the solutions that will be on display. Many companies will be introducing new technologies never before seen in North America. More than 120 Automate conference sessions explore how automation secures a company’s success in a technologically fast-paced world where AI, IIoT, smart manufacturing, cobots, machine vision and other innovations…

Found in Robotics Companies & Businesses, with a score of 42.90

…to make it easy to deploy collaborative automation for tasks such as such as packaging, quality control, materials handling, machine tending, assembly, and surface finishing, regardless of skill level or previous robotics experience.

Found in Robotics News & Content, with a score of 12.46

…in applications such as packaging, quality testing, material handling, machine tending, assembly and welding, currently represent 3% of global robot sales, according to the International Federation of Robotics, but the share is expected to rise to 34% of a $25 billion market by 2025. “This growth will most definitely depend on cobots being used in more applications,” Iversen added. “Their small footprint and ability to work safely alongside humans make them ideal for small and medium-sized manufacturers who need to compete globally. Cobots are also increasingly integrated into very large manufacturers such as automotive plants, where they are taking over…

Found in Robotics News & Content, with a score of 31.15

Yaskawa and Clearpath have partnered to develop a mobile machine tending and material movement solution ideal for shop floor environments. This fully integrated solution will feature a Motoman MH12 robot equipped with end-of-arm tool and vision system, mounted on Clearpath’s OTTO 1500 self-driving vehicle. This project is currently under development and supported under the advanced research division of Clearpath. “Our partnership with Clearpath will provide industry with a robust, tightly integrated solution for moving robots to the work in a very flexible and dynamic way,” said Roger Christian, divisional leader, new product development at Yaskawa Motoman. “This autonomous modular solution…