Editors’ Picks

Found in Robotics News & Content, with a score of 13.32

…company will display its GoFa collaborative robot equipped for welding; a live 3D printing demo featuring ABB’s 3D Printing PowerPac for ABB’s RobotStudio simulation and offline programming software; the MiniMAC robotic grinding cell from ABB Value Provider MESH Automation; a vision guided FlexLoader machine tool tending cell; and the Cobot FlexTrainer education cell for interactive classroom training. “ABB has continually developed cutting-edge products and support programs to help a wide variety of manufacturers and their employees become more productive, resilient and adaptable. Our IMTS exhibit will showcase a number of these innovations, many of which have opened up robotic automation…

Found in Robotics News & Content, with a score of 17.59

…some companies we saw showcasing interesting cobot use cases. Welding is a hot application At Vectis Automation’s booth, Sam Eckdahl showed off his company’s welding and plasma cutting end-of-arm tools (EOAT). He said it takes years of practice for a welder to become a master of his craft. With the use of robots, companies can get that precision in less time. “It is extremely difficult and takes a long time to get proficient at welding, at least to the point where you can make a career out of it,” Eckdahl said. “I’m not a welder by any means, but I…

Found in Robotics News & Content, with a score of 9.89

…company said the cobot's seventh axis enables continuous dispensing, welding, and material-removal applications regardless of access angle and without the need to reorient the arm, which allows for a smaller footprint and higher productivity. “Automation with conventional 6-axis robots would not have been possible in this case,” says Ingo Rathmann, managing director of Project Automation & Consulting GmbH. “Since it can reach around corners, the 7-axis KR1018 can be used in confined spaces.” The company said the cobot’s easy-to-use interface and plug-and-play nature make it accessible to small- and medium-sized enterprises (SMEs) without robot engineers. Dieter Pletscher, global sales manager…

Found in Robotics News & Content, with a score of 8.87

…lift up to 500 lb. for tasks such as welding and decommissioning nuclear power facilities. The Guardian HLS is a pneumatic heavy-lifting system for quickly lifting armored tactical vehicles and other large payloads. Sarcos meets challenges with humans in the loop Despite COVID-19 and economic worries, supply chain snafus and worker shortages have helped companies understand the value of automation, said Kiva Allgood, president and CEO of Sarcos. “The pandemic has been an accelerant for robotics, as companies have had to rewrite their standard operating procedures or SOPs,” she told Robotics 24/7. “Companies are desperate for new ways of doing…

Found in Robotics News & Content, with a score of 10.25

…continues to grow in the wake of digitization. Whether welding, painting, soldering, or palletizing, industrial robots work dynamically. A flexible multi-axis dress pack such as triflex® R from igus makes it possible to guide and secure cables and hoses used on multi-axis robots. igus has developed the i.Sense TR.B, a real-time breakage monitoring system for the multi-dimensional triflex R robotic dress pack to detect potential chain breaks due to extreme loads and avoid unplanned machine breakdowns. Smart real-time condition monitoring With i.Sense TR.B, customers can increase the safety of their robot systems with an investment of just a few hundred…

Found in Robotics News & Content, with a score of 10.83

…40 pounds (5–18 kg) to automate a variety of tasks, the company said. The 7th axis enables continuous dispensing, welding, and material removal applications regardless of access angle, without the need to reorient the arm. Kassow and Industrial Control will have booths at the Advanced Manufacturing Expo in Grand Rapids, Mich. later this month from Aug. 11 to 12. Kassow will be at Booth 700 and Industrial Control will be at Booth 712.

Found in Robotics News & Content, with a score of 9.78

…revenue of $83 million, which is up 8% from last year. The company said one particular growing application is welding. The company said it has also increased its revenue from original equipment manufacturer [OEM] channels.

Found in Robotics News & Content, with a score of 15.07

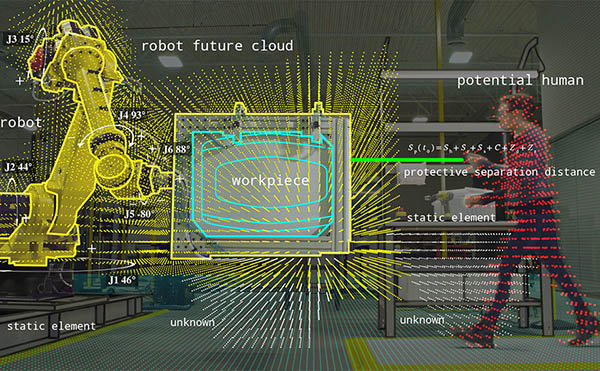

…Inc. has commercialized collaborative robots and AI for automated welding in pipe-fabrication shops. The startup has raised $3 million and is based in North Vancouver, British Columbia. It offers the Spool Welding Robot (SWR), the SWR+HyperFill integrated dual-torch system, the NovEye vision and image-processing system for fully automated welding, and NovSync for data analytics. Rokae Technology Co. in Beijing provides a cobot, a six-axis robot, and the Titanite control system, as well as custom support. Founded in 2015, the company has received $138 million and partnered with German firm Jaeger Engineering to expand in the growing European market. Veo Robotics…

Found in Robotics News & Content, with a score of 5.28

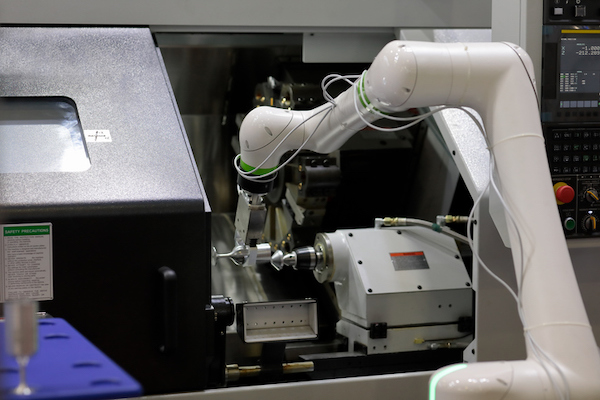

…for exactly what’s needed. Expanding to other verticals, a welding robot becomes a welder, a palletizing robot becomes a palletizer, a sanding robot becomes a sander, and so on, working with the respective OEMs in each case. For example, a robot vendor would work directly with a CNC equipment manufacturer to define and develop a custom configuration. This would include the number of degrees of freedom, the payload, reach, mechanical interface, communications, software, etc. Delivering a functional system that is integrated “out of the box” not only automates the machine-tending task, but it also improves total productivity, which is what…

Found in Robotics News & Content, with a score of 7.37

…handling, palletizing, machining, testing, bonding, screw locking, polishing, and welding. JAKA stated that its collaborative robots have increased production capacity and efficiency, reduced heavy physical labor for human workers, increased worker safety, and mitigated high staff turnover. The vendor claimed that more than 10,000 of its cobots are in operation worldwide, including in the production lines of well-known brands in the automotive, electronics, semiconductor, and other industries. It has established technology centers in Japan and Germany and is working with more than 300 automation companies to provide localized services. Earlier this year, the company launched the new JAKA Pro series…

Found in Robotics News & Content, with a score of 15.40

…products. Sealing: They can also seal products in packaging. Welding: From moving and holding items to welding them together, robots are increasingly popular in metalwork. Cutting, folding, and shaping: Pick-and-place robots can manipulate materials such as cardboard or plastic. Die cutting: Like welding, robots are used to die-cut products. Stamping and printing: Pick-and-place robots can stamp or print on products or packaging. Pick-and-place robots are versatile machines that can be used in a variety of settings. They offer a number of advantages, including reduced labor costs, flexibility, and improved safety. When selecting a pick-and-place robot, it is important to consider…

Found in Robotics News & Content, with a score of 12.88

…into a package at very high speeds. Flexible coordinated welding —This will feature FANUC’s M-900iB heavy-payload material handling robot and two FANUC ARC Mate welding robots. Visual Circular tracking —A FANUC LR Mate 200iD/4S robot uses 2D iRvision to locate random products on a circular conveyor. The cell is equipped with FANUC’s Dual Check Safety (DCS) software, designed to keep operators, robots, and tooling safe. CNC and ROBOMACHINE demos FANUC also said it would demonstrate the following CNC machines and ROBOMACHINEs, including drills, injection-molding machines, and wire electrical discharge machines. They will include the following: FANUC’s visual twin demonstration, which…