Editors’ Picks

Found in Robotics News & Content, with a score of 11.31

…61% in assembly applications and increased 24% in spot welding. The food and consumer goods industry increased orders for robots by 32% in 2016. Robots in these industries can be used in a variety of functions, including improving food safety, performing repetitive primary packaging tasks such as bin picking, tray loading and bottle handling, and assisting with secondary packaging tasks such as case packing, bundling, bagging and palletizing. The robotics, vision and motion control industries are preparing to come together for Automate 2017, North America’s largest automation exhibition and conference April 3-6 in Chicago. More than 300 exhibitors and a…

Found in Robotics News & Content, with a score of 11.29

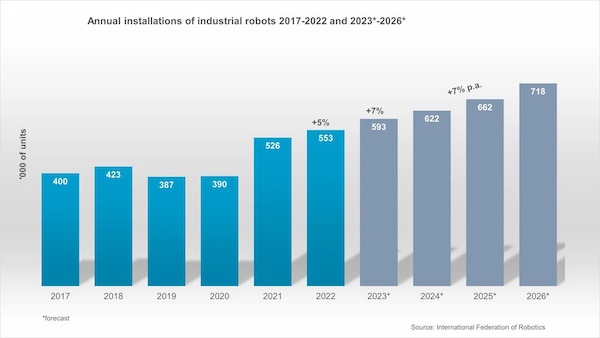

…robots handling part of the workload, whether it’s handling, welding, or assembling, which are the three most common applications of newly installed industrial robots in 2022. Based on data from the International Robotics Federation (IFR), the operational stock of industrial robots has tripled over the past decade, with almost four million robots in use across various industries by the end of 2022. According to the IFR, Asia leads the way in the shift to automated processes, with China in particular installing industrial robots at breakneck speed. In 2022, the country accounted for more than 50 percent of newly-installed industrial robots…

Found in Robotics News & Content, with a score of 11.24

…robots during any downtime. After already seeing promising results, Polar has signed another contract with Formic to add a spot-welding robot into its facility. The company is also considering moving from a two-shift operation to a three-shift operation, allowing the cobots to run around the clock. Altogether, with both systems up and running, Polar said it expects to save around $150,000 per year in operations costs.

Found in Robotics News & Content, with a score of 11.23

…handle delicate operations such as opening soda bottles and welding. These tasks are often considered difficult for machines, and Unitree says G1 can handle these tasks. The G1 is equipped with Intel RealSense D435 and LIVOX-MID360 3D lidar, which can achieve 360° detection and perception. These sensors provide a powerful perception hardware foundation, allowing G1 to better understand the surrounding environment. In addition, the G1 power supply module supports two hours of battery life and quick disassembly. There are two versions of the G1 humanoid robot released this time, the G1 and G1 EDU. The price of G1 is $16K.…

Found in Robotics News & Content, with a score of 11.15

…arm to perform fast and precise pick-and-place, palletizing, and welding tasks, the company added. The new cobot is also suitable for automated optical inspections (AOI), semiconductor and product manufacturing, and food-service preparation, among other applications, Techman Robot said. It can work with autonomous mobile robots (AMRs), it added. “It is the only intelligent robotic arm series on the market provided with a comprehensive AI software suite,” claimed Techman. The TM AI Cobot includes TM AI+ Training Server, TM AI+ AOI Edge, TM Image Manager, and TM 3DVision, allowing companies to train and tailor their systems for their specific needs, said…

Found in Robotics News & Content, with a score of 11.12

…utilize all miniaturization possibilities.” Functions include pick and place, welding, labeling The result of STIWA’s development phase was an automation platform which - depending on the configuration and equipment fitted - can range from 3 to 4 meters, about 9.8 to 13.1 feet. A rigidly linked transport system forms the basis, and the other system components depend on the needs and specifications of the customer. “We can integrate up to 22 function modules, each measuring 90 millimeters [about 3.5 inches] in width, for different work steps,” said Christian Mersnik, a Faulhaber employee who was involved in development from day one.…

Found in Robotics News & Content, with a score of 10.89

…allows for flexibility The cobots can be used for welding, gluing, deburring, material handling, packing, palletizing, and part marking, the company said. Unlike traditional six-axis cobots, OB7 has been engineered with seven-axis maneuverability. It needs no cage and is able to work alongside human operators because it can sense collisions at every joint, a function that triggers a safe stop. To automate OB7, fabricators can add a Productive Robotics parallel electric gripper/end effector, patented robot rolling stand and work table. The cobot is also compatible with other grippers, cameras, and accessories. Machine-tending packages can provide fabricators a complete system for…

Found in Robotics News & Content, with a score of 10.83

…40 pounds (5–18 kg) to automate a variety of tasks, the company said. The 7th axis enables continuous dispensing, welding, and material removal applications regardless of access angle, without the need to reorient the arm. Kassow and Industrial Control will have booths at the Advanced Manufacturing Expo in Grand Rapids, Mich. later this month from Aug. 11 to 12. Kassow will be at Booth 700 and Industrial Control will be at Booth 712.

Found in Robotics News & Content, with a score of 10.75

…automotive technicians, computer support technicians, construction electricians, machinist/CNC technicians, welding/fabrication technicians, medical assistants, and more, the college said. Besides teaching those entering the workforce, the center will also be open to individuals already working in the field looking for additional training or credentials. “The fields of automation and artificial intelligence are evolving and expanding, creating new and exciting careers to meet the needs of today and drive change for the future,” GRCC President Charles Lepper said in a statement. “GRCC is proud to work with our partners in the government, like Senator Peters, and with employers for an Automation and…

Found in Robotics News & Content, with a score of 10.68

…coating and dispensing (+49%), material handling (+24%), and spot welding (+22%). RIA estimates that some 260,000 robots are now at use in North American factories, which is third to Japan and China in robot use. The recent record performance by the robotics market in North America is concurrent with falling unemployment. Last month, the Bureau of Labor Statistics announced that the unemployment rate in the United States reached 4.9%, its lowest level since February of 2008. “Today there are more opportunities than ever before in the robotics industry,” said Jeff Burnstein, president of RIA. “The continuing growth in robotics is…

Found in Robotics News & Content, with a score of 10.65

…top. One vertical that's really moving fast is robotic welding. A few years ago, a shop wouldn't consider a cobot, but it's now our fastest-growing vertical because of the versatility of our robots. Some partners are really being innovative, and smart OEMs are developing standardized solutions and then helping customers with the last 10% of whatever they need to do. With open APIs [application programming interfaces], it's easy to do something specific, like a welding deployment program in the U.S. or Europe. Another cobot application that's really getting traction is screwdriving. It sounds simple, but you have to be very…

Found in Robotics News & Content, with a score of 10.61

…parts for the metalworking industry or heavy lifting in the food-production sector. The seventh axis also enables continuous dispensing, welding, and material removal applications, regardless of access angle, without the need to reorient the arm, said Kassow.