Editors’ Picks

Found in Robotics News & Content, with a score of 28.46

…founder and CEO of DDM. “DDM's 3D printing technology will bolster our core offering and amplify our footprint in additive manufacturing,” says Marc Riquelme, president of Signicast. The partnership between Signicast and DDM highlights advancements in precision casting technologies and opens up new design opportunities. Signicast expects to transition this technology for full-scale production runs in addition to prototyping. Sources: Press materials received from the company and additional information gleaned from the company’s website.

Found in Robotics News & Content, with a score of 28.44

Würth Additive Group last week said that it has signed a global agreement with Markforged Inc., whose Digital Forge product is an integrated metal and carbon-fiber industrial 3D printing platform. The companies said they will incorporate Digital Forge into Würth's additive manufacturing offerings on a global scale. “We are excited to see Würth Additive Group's deep experience and extensive global coverage and the Digital Forge's capabilities come together to overcome global supply chain limitations with customers on a global scale,” stated Shai Terem, president and CEO at Markforged. “Our technology enables some of the world's biggest manufacturers to create digital…

Found in Robotics News & Content, with a score of 28.43

…network with the purchase of a Ti6Al4V Sapphire metal additive manufacturing system. Primus Aerospace is a a leading contract manufacturing partner to aerospace and defense OEMs and Tier 1 suppliers worldwide. Established in 1989, the Lakewood, Colo.-based company has grown into a vertically-integrated manufacturing operation. It also operates a sales and engineering office in Arizona and a distribution warehouse in the Netherlands. Primus' customers include Lockheed, Boeing, Northrop Grumman, General Dynamics, and Raytheon. VELO3D said its integrated, full stack offering of software, hardware, and process-control innovation allows engineers to accelerate product innovation, be more responsive to market needs, and reduce…

Found in Robotics News & Content, with a score of 28.32

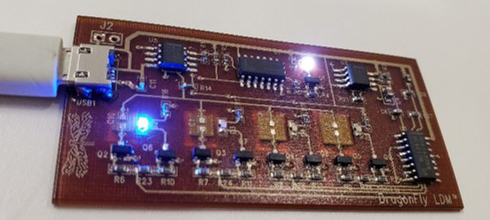

Nano Dimension Ltd. has sold its DragonFly Pro additive manufacturing system for electronics to Istituto Italiano di Technologia (IIT) Biomolecular Nanotechnologies. IIT is a research institution in Italy specializing in promoting technological development and higher education in science and technology. The IIT staff is comprised of approximately 1,700 people from over 60 countries, working together to conduct research in multidisciplinary areas such as robotics, nanobiotechnology, industry, computational science and medicine. The research at the IIT Center for Biomolecular Nanotechnologies in Lecce is focused on the development of micro and nanotechnologies for the human body and for the environment, by studying…

Found in Robotics News & Content, with a score of 28.29

…has developed 3D printed capacitors with the company’s DragonFly additive manufacturing system. These capacitors are embedded in the body of the additively manufactured printed circuit boards (PCBs), saving space and eliminating the need for assembly, the company reports. This type of additive manufacturing of electronics validates the manufacturing applicability of built-in capacitors in PCBs printed with the DragonFly system. Nano Dimension’s testing with capacitors of different 3D dimensions have shown consistent results with statistically validated data. The repeatability results show less than 1% variance. The technology uses the same dielectric and metal traces as in the additively manufactured PCB yielding…

Found in Robotics News & Content, with a score of 28.26

…2019, the 24th annual installment of its report on additive manufacturing (AM) and 3D printing. The 369-page Wohlers Report 2019 includes wide-ranging data on AM materials development and consumption. According to the report, the overall materials segment of the industry saw record growth in 2018. Revenue from metals grew an estimated 41.9%, continuing a five-year streak of more than 40% growth each year. Wohlers Associates says such strong activity among materials suppliers and customers is a telling indicator of the increasing use of AM for production applications. Sales of materials for polymer powder bed fusion were at an all-time high…

Found in Robotics News & Content, with a score of 28.18

At its 31st annual conference, the Additive Manufacturing Users Group (AMUG) presented Elizabeth Goode of Goode Ink with its President's Award. Goode, the eighth to receive this award, is an additive manufacturing veteran and owner of Goode Ink, which provides consulting services for marketing and strategy. For the past nine years, she has been a key advisor to the AMUG Board. Presently, Goode is AMUG’s principal consultant. Elizabeth Goode received AMUG’s President’s Award for her guidance, counsel and support over the past nine years. Image courtesy of AMUG. “AMUG has relied on Elizabeth’s guidance to become what it is today,”…

Found in Robotics News & Content, with a score of 28.13

EWI, an engineering and technology provider of advanced manufacturing in North America, has selected Granta Design's GRANTA MI software to better coordinate its additive manufacturing (AM) work across multiple AM platforms. The software system is currently being deployed. GRANTA MI is made for enterprise materials information management. EWI’s engineering services aim to help companies identify, develop, and implement the best options for their specific applications. Defining a strategy to capture and characterize material information across different AM platforms is currently a challenge. Every AM machine monitors different metrics, and exports data differently. EWI is meeting this challenge by defining the…

Found in Robotics News & Content, with a score of 28.11

America Makes and Air Force Research Laboratory, Materials & Manufacturing Directorate Structural Materials, Metals Branch (AFRL/RXCM), have partnered to offer an additive manufacturing (AM) modeling challenge series, comprised of four individual challenges, with $150K to be divided among awardees. The AFRL AM Modeling Challenge Series represents another innovative approach America Makes, the National Additive Manufacturing Innovation Institute, and AFRL are taking to advance the AM industry. By challenging the brightest minds from industry and academia, the AFRL AM Modeling Challenge Series will be influential in the development of solutions focused on validating/improving the accuracy of model predictions for metal AM.…

Found in Robotics News & Content, with a score of 28.06

…Adaptive3D Technologies LLC, a provider of elastomeric solutions for additive manufacturing. Adaptive3D's products enable the high-volume production of end-use parts through additive manufacturing using odorless, tough, strain-tolerant, tear-resistant, and biocompatible rubbers and rubber-like materials. Adaptive3D offers additive manufacturing polymer resins and specialty polymers to companies around the world in the consumer, healthcare, industrial, transportation, and oil and gas sectors. The company claimed to be a leader in printing and processing rubber-like materials, damping materials, and low-cure stress photopolymers. “The acquisition of Adaptive3D advances Desktop Metal’s vertical integration strategy to grow our portfolio of materials and expand the high-volume applications supported…

Found in Robotics News & Content, with a score of 27.87

Renishaw, a precision engineering and manufacturing technologies company, recently launched its InfiniAM Sonic acoustic process monitoring software to complement its InfiniAM suite of additive manufacturing (AM) monitoring tools. InfiniAM Sonic enables engineers to detect acoustic events within the AM build chamber and turn this data into useful information about build quality. The InfiniAM Sonic package is installed into the RenAM 500Q system as a factory-installed option and includes four acoustic energy sensors to detect vibration in the build. The sensors detect minute vibrations and collect the sound waves so that they can be heard, viewed and analyzed. Using four high-frequency…

Found in Robotics News & Content, with a score of 27.76

Meltio, a manufacturer of wire-laser metal deposition additive manufacturing technology (Directed Energy Deposition, DED), has announced a new partnership with Jupiter Machine Tool (JMT) - an Illinois-based organization for repairing and building CNC machine tools and models across North America. The agreement, along with an Original Equipment Manufacturer (OEM) agreement with Union MechaTronic (UnionMT) of Taiwan, creates a global partnership dedicated to developing and selling Hybrid CNC Machines using Meltio’s wire-laser metal patented DED technology, to support the rapidly growing demand. JMT, Meltio and UMT create unique tri-lateral partnership Jupiter Machine Tool is a provider for the advanced manufacturing industry.…