Editors’ Picks

Found in Robotics News & Content, with a score of 38.91

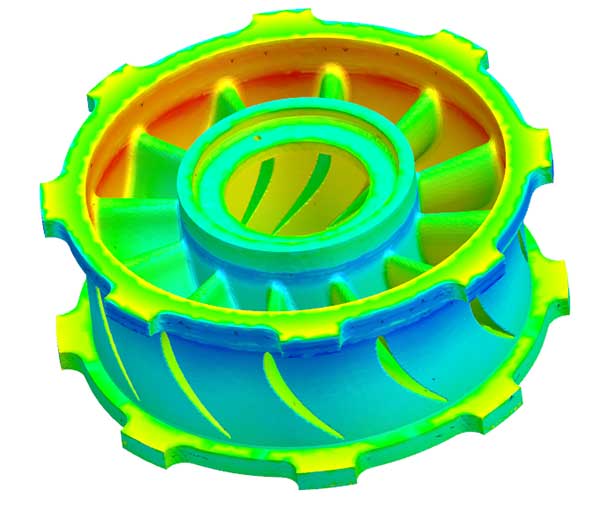

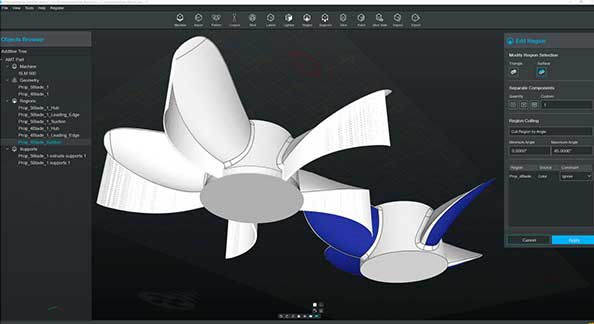

CoreTechnologie debuts new additive manufacturing software. With the new Advanced Lattice module, components can be filled with honeycomb, gyroid, star and many other lattice patterns. With the new 4D_Additive 3D-Printing software, CAD data is prepared as intelligent, exact B-Rep geometry for 3D printing processes and can be saved in common 3D printing formats as well as STEP. With the new Advanced Lattice module, components can be filled with honeycomb, gyroid, star and many other lattice patterns. For the creation of lightweight components, external lattice structures can be created at the push of a button. Optimal heat distribution To achieve the…

Found in Robotics News & Content, with a score of 26.67

…the Atlas 3.6 is one of the largest production additive manufacturing systems on the market with sextrusion technology and an actively heated enclosure, enabling customers to print large parts out of high-performance materials including CF-PEI, GF-PEKK, nylons, ABS and more. The Atlas 3.6 is designed to handle the additional weight and size of the machine, making it compatible with Titan’s Dual Pellet Extrusion and Hybrid Pellet + Filament Extrusion systems. Built with a heavy-duty, rigid design and components, the Atlas 3.6 can maintain accuracy and fast rapid travel speeds with the larger print area, the company says. “When several of…

Found in Robotics News & Content, with a score of 20.24

…says sintering is a critical step in powder metallurgy-based manufacturing processes, including binder jetting. It involves heating parts to near melting to impart strength and integrity, and typically causes parts to shrink by as much as 20% from their original printed or molded dimensions. During the process, improperly supported parts also face significant risk of deformation, resulting in parts that emerge from the furnace cracked, distorted or requiring costly post-processing to achieve dimensional accuracy. Traditionally the solution for shrinkage and distortion was to rely on the experience of industry veterans who, based on repeated trial and error, combine adjustments to…

Found in Robotics News & Content, with a score of 25.16

…Jabil Inc. to accelerate the adoption of large-format, industrial additive manufacturing. Jabil Engineered Materials, a unit of Jabil, which develops innovative polymer formulations and compounds at its ISO 9001 Materials Innovation Center, is working with Titan to qualify and integrate customized materials for use on Titan’s pellet-based Atlas 3D printers. Pellet extrusion on the Atlas enables AM solutions by printing directly with plastic pellets instead of traditional filament. Image courtesy of Titan Robotics/Jabil. Together, the companies are driving the production of large-format tooling for applications in sheet metal forming, composite layups, welding fixtures, molding, casting patterns and end-use parts on…

Found in Robotics News & Content, with a score of 41.94

…Digital Industries Software is expanding its ecosystem for industrial additive manufacturing (AM) through partnerships with Morf3D, Sintavia and Evolve Additive Solutions. Through these new partnerships, Siemens is adding support for new methods of AM production, further strengthening Siemens’ end-to-end solution for industrialized additive manufacturing as part of its Xcelerator portfolio of software and services. Working with Sintavia, Morf3D and Evolve Additive solutions can strengthen Siemens’ end-to-end industrial AM solution while expanding support for service providers and AM machine builders, Siemens says. Siemens is collaborating with Sintavia, a metal additive manufacturer, to connect all phases of the AM process and increase…

Found in Robotics News & Content, with a score of 42.86

…as “a robust solution” for delivering CAD-to-print workflows for additive manufacturing. HP says UBM is an OEM- and process-agnostic tool and is supported by many leading vendors. It offers software tools for build preparation, CAD import, patterning, nesting, labeling, support generation and slicing. The Dyndrite engine supports NVIDIA Enterprise GPUs for computational acceleration. It uses Python as a scripting language, and offers various Python application programming interfaces for automation and workflow integration. HP says this new build prep engine will help additive manufacturing engineers and technicians “improve productivity, efficiency and repeatability in their industrial additive production.” “Additive manufacturing has always…

Found in Robotics News & Content, with a score of 43.01

…developing an industry-accepted guideline for quality assurance of additively manufacturing parts. The consortium includes Equinor, Saudi Aramco, Siemens, Kongsberg Maritime, Voestalpine, Guaranteed, IMI CCI, Kongsberg Ferrotech, Addilan, BMT Aerospace, FIT AG, Howco Group, ImphyTek Powders, Intertek, XDM3D and ExOne. In February, the consortium released a new standard, “Additive manufacturing of metallic parts” ( DNVGL-ST-B203) for the oil & gas sector, which is focused on wire-arc additive manufacturing (WAAM) and laser-based powder bed fusion (PBF-LM). The group is expanding its effort to incorporate more AM technologies, such as binder jetting technology (BJT). “As manufacturers around the world move to new additive…

Found in Robotics News & Content, with a score of 26.45

…of 3D printing as part of a connected, industrial manufacturing process,” says Stefaan Motte, vice president and Managing Director of Materialise Software. “Removing barriers of speed, scale and cost requires a closer integration between software and machine.” Desktop Metal, a leader in mass production and turnkey additive manufacturing solutions, will make the Build Processor available as an add-on software offering with its advanced metal 3D printing solutions, the Shop System for mid-volume manufacturing, and the Production System for high volume mass production. Metal Binder Jetting is carving out a valuable share in the metal manufacturing market by offering specific production…

Found in Robotics News & Content, with a score of 37.90

Stratasys is making additive manufacturing even easier thanks to a new collaboration with nTopology, innovator of next-generation design and engineering software. The two companies are providing a series of accessible, customizable design for additive manufacturing workflows for their users, starting with the FDM Assembly Fixture Generator. Stratasys FDM printers have become powerful, supporting advanced materials like Nylon 12 Carbon Fiber and reaching accuracy and reliability required for use on commercial airplanes and even the International Space Station. But designing with existing engineering software tools still creates long lead times, slowing additive manufacturing's march to pervasive adoption. The new Stratasys |…

Found in Robotics News & Content, with a score of 24.51

…management and automation of 3D printing workflows and large-scale additive manufacturing fleets. They include the new HP Universal Build Manager Powered by Dyndrite, which provides increased productivity and efficiency as well as automation to additive build management for leading 3D printing processes. The company also introduced new digital HP 3D Factory Services to provide customers with facilities and equipment analysis, staffing and training, and help implement production processes. In addition, HP announced the new HP Automatic Unpacking Station, developed in partnership with Rösler Group’s AM Solutions, to enable greater automation for post processing. “Automation, software, and data are key to…

Found in Robotics News & Content, with a score of 14.94

…print multilayer 3D circuitry onto a structural component. This additive manufacturing approach will provide reductions in cost and improvements in yield versus existing methods, as well as increased flexibility for next generation designs. This order is one example of requests for Optomec’s 3D Printed Electronics solution in the medical device market, which now makes up more that 20% of Optomec’s business. Customer applications range from continuous glucose monitors (CGMs) and functionalized catheters to surgical needles and assays for drug discovery. More recently, one of Optomec’s customers is using Aerosol Jet to develop a novel rapid test for COVID that can…

Found in Robotics News & Content, with a score of 10.32

…technology is increasingly being eyed as a complement to additive manufacturing (AM) with the outcome being new workflows that turn out game-changing products. Generative design tools, which include topology optimization and other artificial intelligence-based modeling techniques, burst on the scene these last few years as less expensive and more accessible computing power gives way to new algorithmic-driven design approaches. These design tools provide a whole new level of design freedom by automating the ideation of hundreds of possibilities based off of specified parameters and constraints. The approach helps engineering teams zero in on parts and products that are fully optimized…