Editors’ Picks

Found in Robotics Companies & Businesses, with a score of 48.47

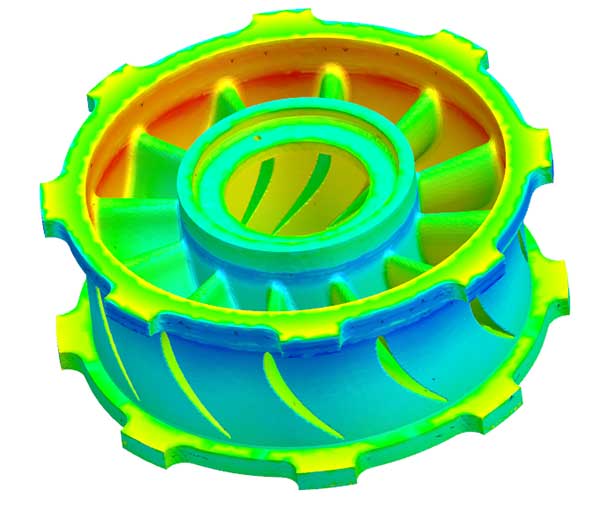

Siemens Digitial Industries said its Simcenter software combines system simulation, 3D CAE and test to help you predict performance across all critical attributes earlier and throughout the entire product lifecycle. By combining physics-based simulations with insights gained from data analytics, Simcenter can help users optimize designs and deliver innovations faster and with greater confidence, according to the company.

Found in Robotics News & Content, with a score of 43.26

…crisis caused by the outbreak of the COVID-19 virus, Siemens is making its Additive Manufacturing (AM) Network (along with its 3D printers) available to the global medical community to speed design and production of medical components. The AM Network connects users, designers and 3D-print service providers to enable faster production of spare parts for machines like ventilators. The Siemens AM network is available globally. According to the company, starting today doctors, hospitals and organizations in need of medical devices as well as designers and service providers with medically certified printing capacities can register for free access to the Siemens AM…

Found in Robotics News & Content, with a score of 40.79

Siemens Digital Industries Software is expanding its ecosystem for industrial additive manufacturing (AM) through partnerships with Morf3D, Sintavia and Evolve Additive Solutions. Through these new partnerships, Siemens is adding support for new methods of AM production, further strengthening Siemens’ end-to-end solution for industrialized additive manufacturing as part of its Xcelerator portfolio of software and services. Working with Sintavia, Morf3D and Evolve Additive solutions can strengthen Siemens’ end-to-end industrial AM solution while expanding support for service providers and AM machine builders, Siemens says. Siemens is collaborating with Sintavia, a metal additive manufacturer, to connect all phases of the AM process and…

Found in Robotics News & Content, with a score of 40.46

…planning data for automation and switching technology products from Siemens via its platform for 3D CAD models. Users of Siemens PLM solutions will now have direct access to digital Siemens components such as switches, controls, relays etc., which are available within Siemens NX, Solid Edge, Teamcenter as well as the CADENAS portal, enabling engineers to quickly integrate them into their product designs. CAD Data as Step Toward Industry 4.0 “Siemens plays a pioneering role when it comes to comprehensively representing constructions as digital twins. Intelligent, native 3D CAD data of the individual components are required to simulate and optimize the…

Found in Robotics News & Content, with a score of 39.32

…the additive manufacturing unit of technology group Oerlikon, and Siemens AG announce a strategic agreement in which Siemens will provide Oerlikon AM with digital enterprise solutions that will help Oerlikon accelerate the industrialization of additive manufacturing. The integration of Siemens’ Digital Enterprise Portfolio into Oerlikon’s software landscape in its AM production and R&D sites will support Oerlikon in actively managing the AM engineering process from end to end using one interface. The technology includes software solutions in engineering, as well as product life cycle management. The long-term objective is to create a digital factory in which Oerlikon AM can see…

Found in Robotics News & Content, with a score of 37.90

…autonomous motion planning for industrial robots, has partnered with Siemens Digital Industries Software division. Realtime’s technology will be integrated into Siemens' Tecnomatix Process Simulate, which the company says will simplify robot programming and workcell coordination by automating motion programming. Manufacturers and integrators will be able to program, simulate, and validate automation, which will simplify the digital commissioning process. According to the company, multi-robot workcells take prohibitive amounts of calendar and scarce engineering time in the simulation phase before going to production. Once deployed, they are inflexible, requiring significant re-programming for every modification. This has made multi-robot workcells cost-prohibitive for most…

Found in Robotics News & Content, with a score of 37.57

OTTO Motors and Siemens Canada yesterday announced that they have partnered for Industry 4.0 technologies, including controls for collaborative autonomous mobile robots (AMRs) and physical asset tracking using Siemens' Real Time Tracking Location Systems (RTLS). “Siemens’ global presence and breadth of product portfolio has been clear to us for as long as we’ve been in business,” said Ryan Gariepy, chief technology officer of OTTO Motors. “Using Siemens controllers to power OTTO fleets will allow our AMRs to achieve a new level of driving performance without compromising safety. For our customers, this means maximum productivity and better ROI.” Oakville, Ontario-based OTTO…

Found in Robotics News & Content, with a score of 37.09

Siemens Digital Industries Software and MaRS Discovery District, a Toronto-based innovation hub, have partnered to provide over 1,400 Canadian science and technology companies with access to Siemens’ Xcelerator portfolio of software and services to support and accelerate the development of autonomous and connected vehicle technologies. The design and simulation software can help companies in the MaRS ecosystem conduct early design development and advanced verification of autonomous function and performance systems. “Through this partnership with Siemens, we will provide our community with access to a complete autonomous vehicle software platform for complex system design, from ideation through realization,” says Oshoma Momoh,…

Found in Robotics News & Content, with a score of 36.83

What can digitalization do for manufacturers? At Automate 2022, Siemens will present the portfolio of hardware, software, and services in its Totally Integrated Automation, or TIA, engineering platform to help both machine builders and manufacturing end users. At the show in Detroit, Siemens plans to display its variable-speed drives, servomotors, motion controllers, PLC (programmable logic controller) automation, robotic integration, network connectivity including RFID, and advanced edge technology. The company will also display its Real-Time Locating Systems (RTLS), a scalable industrial system that provides the locations of people and tangible assets such as robots for better process monitoring and management inside…

Found in Robotics News & Content, with a score of 36.48

Siemens Digital Industries Software and SAS announced a new partnership today that will help companies create new IoT edge and cloud-enabled solutions by applying SAS and open source streaming analytics through Siemens’ MindSphere. Users will gain access to SAS advanced and predictive analytics in MindSphere, which can accelerate the adoption of machine learning (ML) and artificial intelligence (AI) in Internet of Things (IoT) environments. Siemens and SAS will collaborate to engage with new and existing customers and, beginning with streaming analytics, enable near-real-time embedded AI for IoT devices at the edge. The partners expect the solutions to be generally available…

Found in Robotics News & Content, with a score of 36.44

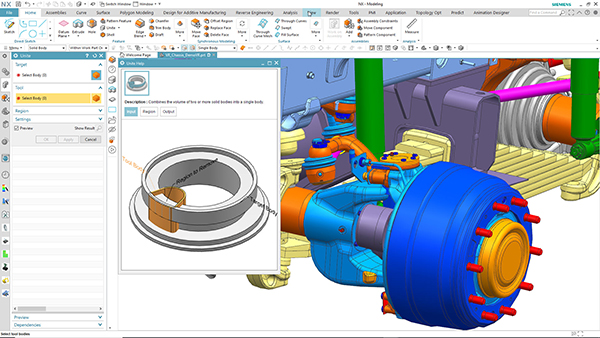

Siemens PLM Software announces an expansion of the Digital Innovation Platform with the introduction of the latest version of NX software, which has been enhanced with machine learning (ML) and artificial intelligence (AI) capabilities. These new features can update the user interface to help users more efficiently use software to increase productivity, Siemens says. The ability to automatically adapt the user interface to meet the needs of different types of users across multiple departments can result in higher adoption rates, leading to a higher-quality computer-aided technology (CAx) system and the creation of a more robust digital twin, the company notes.…

Found in Robotics News & Content, with a score of 36.04

Siemens Digital Industries Software announced a partnership with global semiconductor IP company Arm, that will bring IP, methodologies, processes and tools together to help automakers, integrators and suppliers collaborate, design and bring to market their next-generation platforms faster. This partnership was formed to address challenging issues to realize active-safety, advanced driver assistance, in-vehicle infotainment, digital cockpits, vehicle-to-vehicle/vehicle-to-infrastructure and self-driving vehicles. Key advances in computing and sensor technology are enabling companies to redefine mobility beginning with the integrated circuits and software within automotive electronics systems. The combination of Siemens’ and Arm’s technologies can help automakers and suppliers deliver electronic design and…