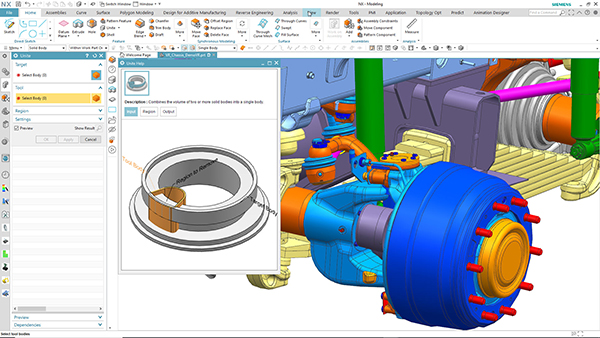

Siemens PLM Software announces an expansion of the Digital Innovation Platform with the introduction of the latest version of NX software, which has been enhanced with machine learning (ML) and artificial intelligence (AI) capabilities. These new features can update the user interface to help users more efficiently use software to increase productivity, Siemens says. The ability to automatically adapt the user interface to meet the needs of different types of users across multiple departments can result in higher adoption rates, leading to a higher-quality computer-aided technology (CAx) system and the creation of a more robust digital twin, the company notes.

The Siemens Digital Innovation Platform is expanding to enable customers to create a comprehensive digital twin of the product, the production environment and of the performance of the product, according to the company. Integrating ML and AI into NX software offers speed, power, efficiency and intelligence through learning, without having to explicitly program these characteristics. The NX Command Prediction module is reportedly the first introduction of the machine learning-enabled NX adaptive user interface architecture to the market, and will be the basis for, and lead to, additional machine learning-driven UI solutions, the company reports.

“Although extensive research conducted in the field of human-computer interaction has resulted in an excellent static interface, we still lack the perfectly-tailored dynamic interface that can suit all users,” says Bob Haubrock, senior vice president, Product Engineering Software at Siemens PLM Software. “The latest version of NX uses machine learning and artificial intelligence to monitor the actions of the user, and their successes and failures, so now we can dynamically determine how to serve the right NX commands or modify the interface to make the individual user more productive. Leveraging this learned-user interface knowledge for CAx environment personalization can help our customers improve overall usage and adoption rates, ultimately leading to a more efficient product development processes.”

Sources: Press materials received from the company and additional information gleaned from the company’s website.

About the Author

Press releases may be sent to them via [email protected]. Follow Robotics 24/7 on Facebook

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up