Xerox and the Naval Postgraduate School (NPS) announces a strategic collaboration focused on advancing additive manufacturing research, specifically 3D printing, which has the potential to transform the way the military supplies its forward-deployed forces, organizations note.

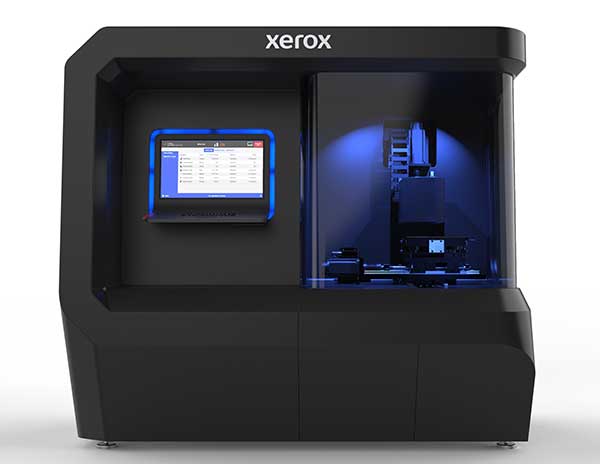

As part of a Collaborative Research and Development Agreement (CRADA), NPS was the first to receive an installation of the Xerox ElemX Liquid Metal Printer on the university campus in December. The Xerox solution will provide NPS faculty and students with hands-on exploration of new ways the technology can deliver on-demand 3D printing of metal parts and equipment.

“The military supply chain is among the most complex in the world, and NPS understands first-hand the challenges manufacturers must address,” says Xerox Chief Technology Officer Naresh Shanker. “This collaboration will aid NPS in pushing adoption of 3D printing throughout the U.S. Navy, and will provide Xerox valuable information to help deliver supply chain flexibility and resiliency to future customers.”

With access to the latest additive manufacturing equipment, NPS faculty and students will use the ElemX printer to conduct thesis research to develop new capabilities for the Navy and Marine Corps.

“As the Department of the Navy’s applied research university, NPS combines student operational experience with education and research to deliver innovative capabilities and develop innovative leaders with the knowhow to use them,” says NPS President retired Vice Adm. Ann Rondeau. “This collaborative research effort with Xerox and the use of their 3D printing innovations is a great example of how NPS uniquely prepares our military students to examine novel approaches to create, make, prototype and manufacture capability wherever they are.”

“This partnership is about the strategic ability of the Navy to have sailors on ships with the capability through creativity and technology to advance their operations at sea,” Rondeau adds. “Through collaboration, NPS and Xerox are helping build a Navy for the 21st Century.”

The Xerox ElemX printer uses aluminum wire to fabricate end-use parts that can withstand the rigors of operational demands, Xerox reports.

“Global supply chains leave industries like aerospace, automotive, heavy equipment, and oil and gas vulnerable to external risks,” says Tali Rosman, vice president and general manager, 3D Printing, Xerox. “Our goal is to integrate localized 3D printing into their operations, and the real-time feedback from NPS gives us actionable data to continuously improve the ElemX.”

The Collaborative Research and Development Agreement (CRADA) does not imply endorsement of Xerox or its products by the Naval Postgraduate School, the Department of the Navy, or the Department of Defense.

About the Author

Press releases may be sent to them via [email protected]. Follow Robotics 24/7 on Facebook

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up