In the age of the Internet of Things, an increasing number of materials handling systems (MHS), and even components of the larger systems, are gaining both sensors and intelligence.

However, existing warehouse control systems (WCS) have not been engineered for this new age.

Going forward, we believe that warehouse management (WMS) and warehouse control systems architectures need to be re-conceptualized to enable optimum warehouse performance.

Materials Handling Systems and the Internet of Things

In one definition of the term “Internet of Things,” almost all objects have sensors, connectivity to a broader environment, and intelligence. Sometimes the object has just a sliver of intelligence; but it can be much more substantial. Objects can be products, equipment, containers, or other things as well. For our purposes, the objects we are focused on are forms of materials handling equipment.

Traditionally, we said that warehouses were operated in either a manual, semi-automated, or highly automated fashion. In a manual warehouse, pickers used carts, forklifts, and other “dumb” forms of carriage to go to picking locations, gather the inventory, and deliver those goods to the shipping dock. However, forklifts are becoming intelligent. With the right kind of control system, a warehouse using forklifts becomes semi-automated.

The Intelligent Forklift

Traditionally, the forklift was the backbone for manual material movement in a factory or distribution center, a “dumb” piece of machinery that was entirely dependent upon the operator. In contrast, modern forklifts epitomize the evolution to intelligent, sensor-enabled equipment. Today’s “smart” forklift includes diagnostics that allow the equipment to signal when it needs to be serviced, speed controls, anti-slip technology that monitors wheel spin and improve traction on slick floors, collision detection, fork speed optimization, and more.

Intelligent forklifts promote new process flows in the warehouse. When integrated to a WMS, the forklift’s fork can be raised or lowered much quicker. The WMS directs a forklift to a pick location. Once at the location, the forklift knows whether the pallet to be picked is being stored at a height of three feet, six feet, etc. The operator pushes a button on the console and the forks move at the maximum safe speed, a speed considerably faster than the operator would be apt to move them.

Speed controls can be used to help ensure safety. For example, RFID tags placed in the floor can signal the forklift that this is a busy section of a warehouse traversed by humans. The forklift automatically knows it cannot exceed a set speed, for example two mph, and the governor automatically limits the top speed to two mph in those sections of the warehouse.

In mixed case picking, intelligent forklifts can integrate with pickers wearing voice systems, follow them up an aisle, lift the pallet to the correct ergonomic height for picking based upon the location of the inventory in the warehouse racking, and then, when ordered to do so, autonomously (without a human driver) make the trip to a shipping dock for unloading.

The most intelligent forklifts today are built with real-time location systems that allow drivers to proceed to a specified location and pick up (or put down) a load without the need for drivers to scan the location to prove that they have picked up (or delivered) the right load. This solution is designed for full pallet moves in either a warehouse with racks or a bulk warehouse in which pallets are stacked on top of each other.

The Intelligent Material Handling Component

Intelligence is also becoming more componentized and distributed in conveyor and sortation systems. Modern conveyors resemble modular Lego blocks. Distinct segments of the conveyor can have their own sensors and intelligence. This makes this form of materials handling more flexible and the investment in these technologies less risky.

For example, imagine a warehouse in which daily throughput volumes have increased over time. One can now pop in a new five-yard segment containing the conveyor, a divert sensor, the sortation device, and a motor. If the WCS signals a divert, the distributed control at the component level can kick the inventory off the conveyor, and the engine on that segment of the conveyor revs up to close the gap with other items on the conveyor.

The Traditional View of WMS and WCS

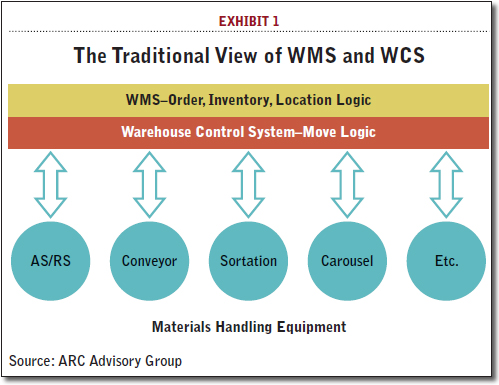

The following diagram shows how WMS and WCS have traditionally been visualized (see Exhibit 1). In this example, the WMS contains the order, inventory, and location logic. The WCS has the move logic. The WMS knows that this many units of this SKU need to be picked and where that inventory is located.

When inventory is inducted into the automated materials handling system, it is the job of the WCS to move those items. The WCS does not need to know what inventory is being moved, or how that inventory fulfills customer orders.

Actually, it’s much more complicated than that. If we are talking about moving goods by conveyors, the traditional view is apt. But if we are talking about automated storage and retrieval systems (AS/RS), the WCS also needs to have the location logic for the goods stored in the AS/RS. And the providers of highly automated materials handling solutions will tell you that in particular situations for some process flows, the WCS also needs to contain a subset of inventory data.

Still, at its heart, a traditional WCS is all about moving goods via intelligent materials handling systems. Because traditional forklifts are not intelligent, the idea of using WCS to integrate with forklifts in this example would have been unthinkable just a few years ago.

A New Conceptualization of the WMS/WCS Stack

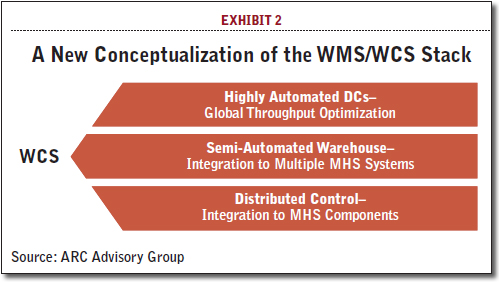

Warehouse control in the age of the Internet of Things, requires a new conceptualization of WCS. The new view segments warehouse control into three segments (see Exhibit 2).

In highly automated warehouses, a warehouse is designed from the ground up around end-to-end flows based upon “advanced” materials handling systems. Because different materials handlings systems operate at different speeds and have different carrying capacities, a key job for the WCS is to achieve global throughput optimization by properly buffering and throttling the various subsystems.

In a semi-automated warehouse, one key aspect of the WCS is to solve the “islands of automation” problem. In many warehouses, over time new materials handling systems have been added. For example, a short conveyor section in the shipping department one year, a carousel a couple of years later, conveyors in the receiving department after that, and so forth.

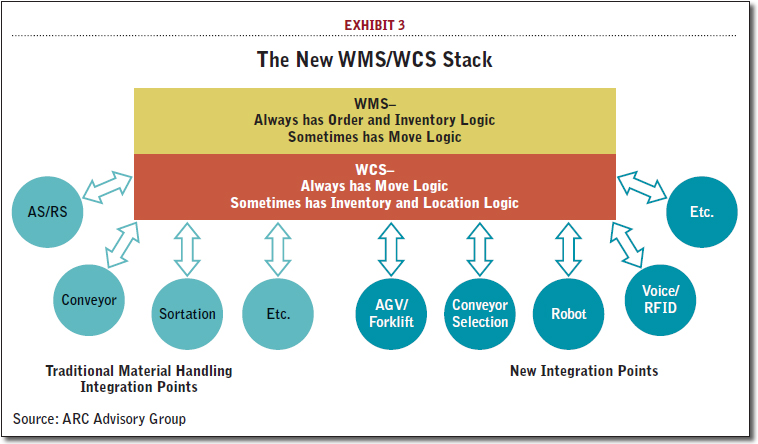

Each of these distinct materials handling systems has its own control system that needs to be integrated with the WMS. This ad hoc process of integrating to the WMS drives up costs and makes WMS upgrades all but impossible. Thus, a key job of a WCS in a semi-automated warehouse is to be the central integration point between the WMS and the various material handling systems that have been added over time (see Exhibit 3).

A forklift that integrates through a control layer to some of the logic in a WMS to move its forks faster and more efficiently is now engaged in a move activity. That means intelligent forklifts need to be part of a larger warehouse control solution in this new WMS/WCS stack.

A small section of a conveyor, with its own logic and sensors to allow it to move items within its small domain more efficiently, is also engaged in a move activity. Wii technology provides a useful analogy of what is likely to come to the warehouse in the future. The Wii is an electronic game that senses the motions of players; it is inevitable that this form of technology will come to the warehouse.

For example, it is possible to imagine a worker loading a truck supported by an extendable conveyor. One can imagine that worker making hand gestures to speed up or slow down the conveyor speed and other motions that signal the conveyor to extend further into the trailer or begin to pull back into the warehouse. Thus, we clearly need to visualize a WCS as integrating with new forms of sensor intelligence.

There’s never been a neat line separating the types of logic contained in a WMS and a WCS, and this isn’t going to change. Semi-automated warehouses also need to attempt to attain global throughput optimization. However, the logic to do this is frequently found in a WMS, sometimes in the WCS, but more often will require cooperation between the two.

For example, if a manual pack station is the warehouse bottleneck, a conveyor feeding those stations needs to be able to throttle up and down to provide a buffer to avoid overwhelming those stations. Acting as a control tower, a WMS can utilize visualization to allow a warehouse manager to see whether work is proceeding on schedule or slowing down at those stations.

If the pack stations are falling behind, the manager can reposition labor from other sections of the warehouse to ramp up warehouse throughput.

In highly automated warehouses, the WCS technology is critical. In these warehouses, local zone needs must be balanced to speed up or slow down, with global optimization of all move activities occurring in the warehouse. While this will create new hurdles, it is likely that agent-based software development will be needed to solve this requirement.

Meeting These New Challenges

Clearly, our key recommendation for materials handling and WMS suppliers is to reexamine their WMS/WCS architectures and ask themselves whether these can support far more types of materials handling systems and sub components of those systems that have sensors, connectivity to a broader environment, and intelligence.

In an era of distributed intelligence, a robotic revolution, and an environment in which new forms of “goods-to-person” automation are arising, it is inevitable that we will see value migrate from certain types of solution providers to others. Value will migrate away from solution providers focused on highly automated warehouses based on fixed (bolted down) material handling systems.

That is because highly automated warehouses don’t flex well as order volumes and profiles change, and thus can carry a high-risk profile even though they can provide un-patrolled throughput. Value is beginning to migrate toward more mobile (non-bolted down) forms of materials handling used in goods-to-person processes.

WMS and materials handling suppliers that can provide WCS solutions that can treat a forklift as an advanced form of automation, allow companies to add new forms of automation while protecting the WMS upgrade path, and provide logic that helps optimize throughput (even in warehouses where bottlenecks may shift over time between manual and materials handling system choke points), will be the winners in this brave new world.

About the Author

Steve Banker is the service director for supply chain management at ARC Advisory Group. He can be reached at [email protected].

Related Article: What Can Warehouse Execution Systems Do For Your Distribution Center Operations?

Article topics

Email Sign Up