Gone are the days of a manufacturer buying a robot arm, only to struggle with figuring out how to integrate it in a workcell. Turnkey robotic applications, complete with the necessary hardware, software, sensors, and interfaces, will drive automation in 2023, claimed Universal Robots A/S.

“In 2023, cobot automation will become more sophisticated yet more straightforward to use,” predicted Joe Campbell, senior manager of applications development and strategic marketing at Universal Robots (UR). “We are going to continue seeing phenomenal growth within complete robotic systems for applications such as welding, palletizing, and machine tending, propelled by UR partners creating full solutions powered by our collaborative robot arms.”

Sales of UR cobots for integration in OEM (original equipment manufacturer) systems grew about 50% in 2022, said Universal Robots. The company said it began the new year with more than 80 OEM integration partners and over 300 UR+ partners launching application kits and components certified to work with its cobots across industries.

Welding a growth area for cobots

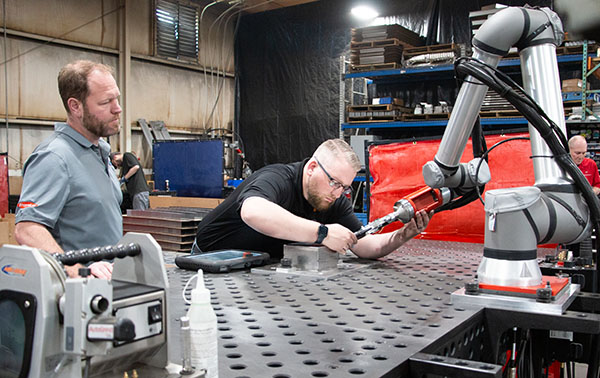

A significant share of new cobot-powered turnkey systems now handle welding applications, noted Universal Robots. The Odense, Denmark-based company said its welding channel grew by more than 80% last year.

New cobot welders hit factory floors in places such as Raymath, a sheet metal manufacturer in Ohio. Greg LeFevre, CEO of Raymath, was able to visit THG Automation, a local UR partner offering cobot welding systems.

“Within the four hours that I was there, we programmed 20 weld points,” he said. “I was actually practicing and sampling on the parts that I was going to make.”

“It proved to me that if I can program this in four hours and actually have my parts running, there’s no doubt this can work in our shop,” added LeFevre. “I wrote the purchase order that same night.”

Raymath deployed four UR cobot-powered welders that now handle hard-to-staff processes with half the number of operators. The robots weld at twice the speed, resulting in 4x productivity improvement, said LeFevre.

Universal Robots, which is part of Teradyne Inc., said it declared January “National Cobot Awareness Month” to help manufacturers discover collaborative robots.

“We want to give businesses a head start by sharing these inspiring ‘Aha moments’ on how cobots can help them solve business challenges, offering them the opportunity to find a local UR partner and try a cobot firsthand,” Campbell said.

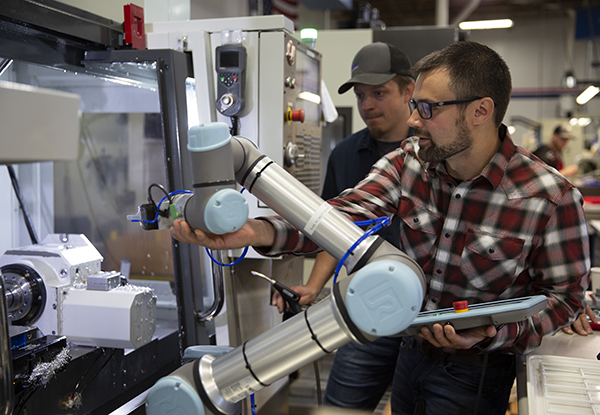

Cobots with higher payloads, longer reach offer modular production

As more companies consider automating with collaborative robot arms, many will want them to handle heavier payloads. In 2023, the new UR20 cobot becomes available to customers.

The UR20 is built for 20 kg (44 lb.) payloads, with faster speeds and advanced motion control all within a lightweight, small footprint system, said Universal Robots.

“The 20 kg payload capacity will transform industries such as palletizing, while its 1,750 mm [5.7 ft.] reach is eagerly anticipated for use in welding and machine tending,” said Campbell.

He explained that the new robot is light enough to be unbolted and relocated or attached to a heavy base with wheels.

“Modular automation is another key trend in 2023,” Campbell said. “I expect us to see more reconfigurable robotic work cells than ever before.”

Customers at the heart of product development

Although Universal Robots targets robot collaboration in the workplace, human collaboration is what drives innovation, it said. The company recently reorganized its product-creation teams to focus on understanding the problems customers are facing before designing systems.

“Customers understand their own needs better than anyone else, and we will increasingly involve end-users in product development,” said Campbell. He said he expects co-development projects in which UR and customers develop systems together to expand in 2023 and beyond.

“Ultimately, these collaborations allow customers to directly influence the product they are buying, while at the same time delivering valuable feedback—meaning we will be able to launch a product to the benefit of the whole market,” Campbell said.

Universal Robots' product portfolio includes the UR3e, UR5e, UR10e, UR16e, and UR20, reflecting a range of reaches and payloads. Each model is supported by a wide selection of end effectors, software, accessories, and application kits in the UR+ ecosystem. The company said it has installed over 50,000 cobots worldwide.

Article topics

Email Sign Up