Smart Robotics today announced three new versions of its Smart Palletizer collaborative robot system. The Eindhoven, Netherlands-based company said its newly engineered offerings will offer warehouses more options to automate and optimize warehouses in response to growing labor shortages.

“Since the Smart Palletizer can take over physically demanding, repetitive tasks, we’re pleased to introduce our new product line to the market to be able to serve a larger audience,” stated Johan Jardevall, CEO of Smart Robotics. He added that it's part of “our mission to lessen the pressure on warehouse employees’ risk to their overall health.”

Smart Robotics offers automation as a service for warehouses, fulfillment centers, and logistics facilities worldwide. The company noted that collaborative robot arms allow for more integrated workspaces and can safely interact with human workers.

In addition, Smart Robotics said its cobots can take over repetitive and physically straining tasks, such as palletizing and picking and placing items.

Smart Palletizer re-engineers product line

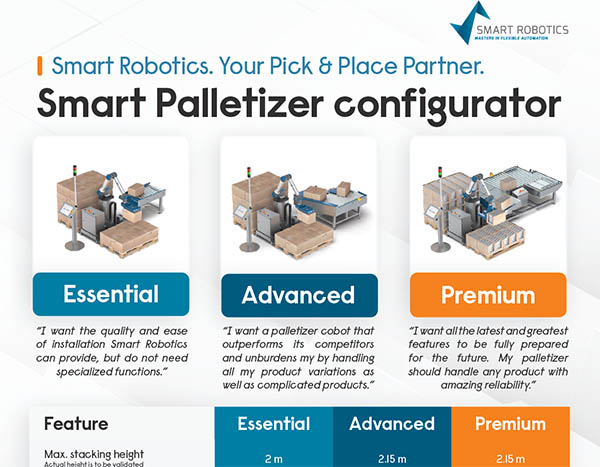

Smart Robotics said its products now come in three versions:

- Essential Version: This is a robust system that is capable of handling a large variety of products, claimed the company. This version is compact, can handle multiple different stacking patterns, and can readjust itself as needed.

- Advanced Version: This version is able to stack a larger variety of boxes in terms of size and allows for more complex stacking patterns. The system can also stack boxes to a greater height and can integrate directly into a warehouse management system (WMS).

- Premium Version: “There are almost no limits to what this system is able to do,” said Smart Robotics. It can stack packaged baked goods and pharmaceuticals, as well as handle open boxes. This version of the Smart Palletizer offers the best in next-generation, end-of-line automation, said the company.

By having various versions to choose from, customers are able to select the distinct Smart Palletizer that best matches their needs, said Smart Robotics. The company's current customers, ranging from snack and confectionary producers to suppliers of pharmaceutical products, are already putting the new versions to use.

New customers from the warehousing sector, with greater product variety, will benefit from the new versions’ adaptability, said Smart Robotics.

Smart Robotics touts user-friendliness

Each version of the Smart Palletizer is safe to interact with and is highly user-friendly, according to Smart Robotics. The end-of-line cobot combines existing infrastructures with automation for warehouse optimization, while also creating better working conditions, said Smart Robotics.

All three versions of the Smart Palletizer come with the option of an all-inclusive service and maintenance contract. Smart Robotics said its dedicated service team will ensure smooth operation for the lifetime of the system.

Each version of the Smart Palletizer is easy to integrate in the warehouse, automating essential tasks without disrupting workflows, said Smart Robotics.

Article topics

Email Sign Up