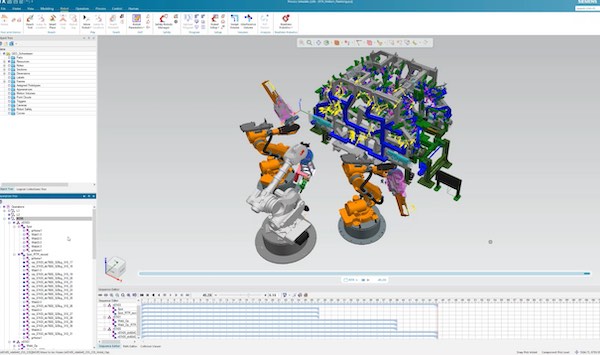

Realtime Robotics Inc. today announced that it has integrated its RapidPlan motion planning and control software for industrial robots with Siemens Process Simulate. The companies said this will enable Siemens customers to use RapidPlan without leaving Process Simulate as part of their regular workflows.

“Robot programming and task planning has been a time-consuming—and frankly, difficult—process for far too long,” said George Konidaris, co-founder and chief roboticist of Realtime Robotics. “We founded Realtime Robotics to change that once and for all.”

“This integration with Siemens will make it much easier for those using Process Simulate to eliminate collisions and quickly take robot task plans from simulation to reality,” he added.

Founded in 2016, Realtime Robotics said its technology generates motion plans in milliseconds for industrial robots and autonomous vehicles. The Boston-based company said its RapidPlan software allows robots to function together in unstructured and collaborative workspaces, as well as to react to dynamic obstacles as soon as changes are perceived.

RapidPlan and Process Simulate provide smoother user experience

RapidPlan can help manufacturers design and deploy industrial automation faster and more efficiently, according to Realtime Robotics. By automating the programming, deployment, and control of robots, all robot movements are autonomously generated and choreographed, it explained.

Users of RapidPlan can create digital twin simulations of their workcells. They can then simply point and click on robots and target points to create and visualize collision-free task plans, saving weeks to months of programming time per project, Realtime claimed.

Since at least 2020, Realtime Robotics has partnered with Siemens to simplify robot programming and workcell coordination through the automation of motion programming. Siemens Process Simulate is part of the Tecnomatix portfolio.

The companies said the integration of their software will let Siemens customers easily visualize, prioritize, and simulate robot task plans. Users will also be able to validate them through virtual commissioning.

With Realtime Robotics for Siemens Process Simulate, positions and waypoints can be updated without reprogramming. The integration also provides automated and collision-free interlock programming to reduce time-consuming manual tasks, said the companies.

Realtime added that users can install RapidPlan as an add-on that can be downloaded directly from the Siemens website. Once installed, the plug-in is accessible directly from the Process Simulate ribbon. Once executed, RapidPlan can handle the collision-free motion planning while the user continues working on a project.

The company said the process of programming and iterating on a robot cell with up to 16 robots at a time is “blazing fast.” Users just need to click on a few buttons and follow their usual Process Simulate processes, it said.

In addition, Realtime and Siemens said they have added support for servo weld guns.

Siemens, Realtime tout integration benefits

Realtime Robotics has been working with Siemens for several years.

“We want RapidPlan to be as practical and easy to use as possible, and started developing the integration when we heard from multiple customers that it would save them a lot of time without requiring them to change their existing robot cell programming processes,” Alejandro Suarez, strategic program manager at Realtime Robotics, told Robotics 24/7.

The integration of RapidPlan and Process Simulate will result in a “massive reduction in programming time,” said the companies. Siemens and Realtime also cited the following benefits:

- Streamlined cell commissioning—With RapidPlan, customers can get paths that avoid collisions between robots and with other objects in the cell.

- Improved decision-making—Simple, straightforward logic is made possible by the software, making it easy to intuitively configure robots or optimize for cycle time.

- Quickly evaluate and validate options—The need to undertake lengthy, laborious manual robot path validation is eliminated as RapidPlan quickly evaluates changes and validates available options.

- Work directly in Siemens Process Simulate—There’s no longer a need to switch between programming and simulation programs. RapidPlan integrates with Process Simulate, and can run either on the same PC or in a separate environment.

- Automatic viapoints and interlocks—Process Simulate automatically records RapidPlan generated viapoints, removing the need for manual viapoint and interlock validation.

“Customers are very excited to hear this is available,” said Realtime Robotics. “We've seen lots of proactive interest pouring in from both joint customers with Siemens and long-time supporters of our technology. This integration simplifies their existing processes and supports their use of Process Simulate they are comfortable with.”

“The combination of Process Simulate with Realtime Robotics’ automated motion planning and interlocking has provided a significant improvement to our efficiency, reducing our offline programming efforts by more than 80%,” said Michael Schaubmayr, group manager for mechanical engineering simulation at Valiant TMS. “This presents to us a tangible and strategic advantage in the industry.”

Realtime Robotics to show innovations at IMTS

Last week, Realtime Robotics raised $14.4 million in funding beyond its $31.4 million Series A round in June.

The company recently announced additional funding, and will be showcasing its technology at the annual International Manufacturing Technology Show (IMTS) 2022 this week in Chicago.

Article topics

Email Sign Up