Picking robots are keeping pace with growing supply chain demand. Plus One Robotics Inc. yesterday announced that its robotic parcel-handling platform has performed more than 1 million picks per day in production and reached over half a billion parcel picks globally.

“Our north star will always be to increase our customers’ total picks per day,” stated Erik Nieves, founder and CEO of Plus One Robotics. “To everyone at Plus One, 500 million represents more than just parcels picked; it’s a milestone demonstrating that our clients have come to rely on our tech every day. That’s a half-billion parcels that were sorted on time and at quality.”

E-commerce currently accounts for 20% of total retail globally and could reach 30% by 2030. This growth, in combination with ongoing labor shortages, makes the implementation of automation a key strategy for shipping and fulfillment companies across the world, noted Plus One.

The global warehouse automation market is projected to experience a compound annual growth rate (CAGR) of 15% from 2022 to 2030.

Plus One uses AI, humans in the loop

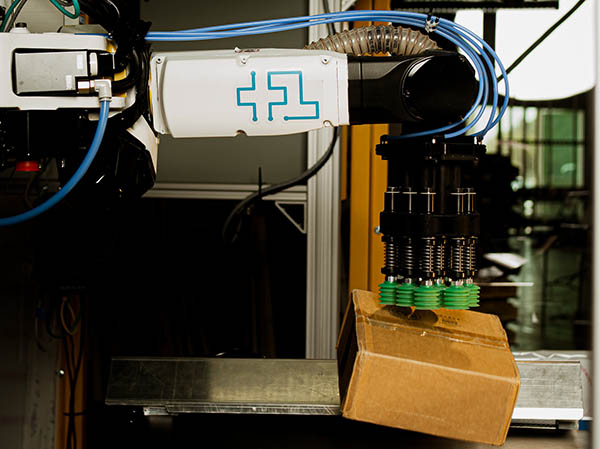

Founded in 2016 by computer vision and robotics industry experts, Plus One said its systems combine artificial intelligence, computer vision, and supervised autonomy. The San Antonio, Texas-based company's platform picks parcels for leading logistics and e-commerce organizations in the Global 100. Plus One has offices in Boulder, Colo.; Pittsburgh; and the Netherlands.

The company's PickOne system for parcel induction and depalletization use 3D sensors and AI-powered software with optimized robot grippers to pick and place disparate parcels within sortation or distribution centers.

Plus One Robotics claimed that its human-in-the-loop (HITL) approach with Yonder is unique. Remote or on-premises employees can supervise multiple robots from any location, speeding its ability to handle exceptions and facilitating machine learning that keeps downtime to a minimum. This enables 24/7 fulfillment, said the company.

Robot arms catch up to mobile platforms

“Robot arms are lagging behind AMRs [autonomous mobile robots],” Nieves told Robotics 24/7. “AMRs are seen as a reversible business decision, and there is no 'halo customer' in this space, like General Motors, that OEMs could point to and say, 'If it works for them, then it works for us.'”

“There's no single player in the robot arm ecosystem, despite Amazon, Ocado, Kindred, and FedEx,” he added. “Consolidation will happen, but Plus One is fortunate. We started with the application rather than the technology. The only metric that matters for us is the number of picks around the world.”

“We've had a lot of success with mixed depalletizing, which people don't want to do,” said Nieves. “Companies want to reach boxes at the bottom, not the top at induction.”

“We say, 'Robots work, people rule,' because people are more flexible. They can begin decanting and then do packout and then do palletizing,” he said. “You need to find a task people hate and processes that lend themselves to shifts. Then you can dedicate a piece of automation for a favorable return on investment.”

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up