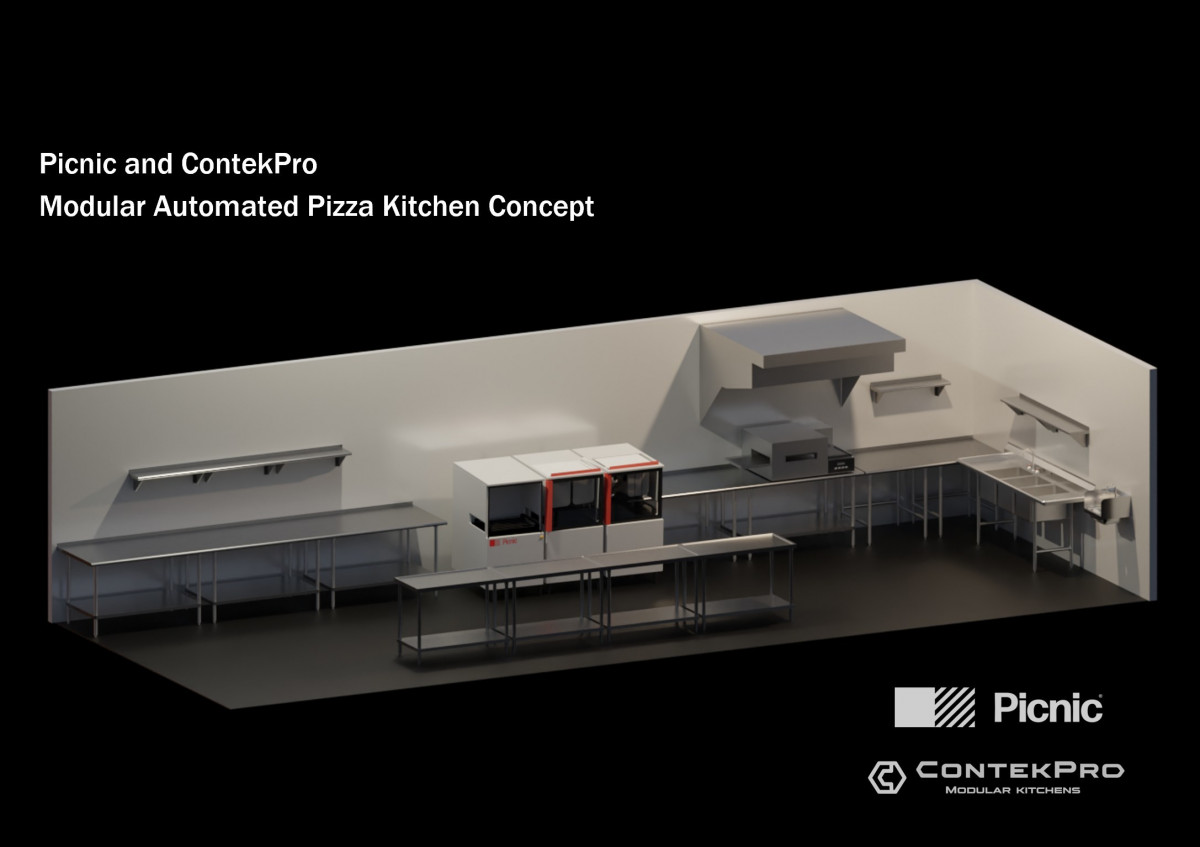

Picnic Works, a Seattle-based developer of kitchen automation technology, yesterday announced a partnership with ContekPro, a Portland, Ore.-based manufacturer of modular kitchens.

The companies said they are working together to create factory-built pizza kitchens for commercial foodservice providers.

ContekPro will manufacture kitchens with an integrated Picnic Pizza Station that uses robotic automation to assemble up to 100 pizzas per hour with just one member of the kitchen's staff.

ContekPro said it uses leading-edge software and proprietary applications to run efficient and sustainable manufacturing operations. The modular kitchens are designed and manufactured in the U.S.

ContekPro builds kitchens fast

The company added it focuses on predictable scheduling, transparent processes, and cost accuracies while producing kitchens 50% faster than traditional construction methods.

With more than 150 projects deployed to customers in the U.S., the Caribbean, and Africa, ContekPro’s customers include SeaWorld, Boyne Resorts, Discovery Land, Providence Health & Services, the US Army, and Fluor construction.

“Kitchen innovation can help increase profits, reduce waste and operating costs, and improve guest satisfaction,” said Scott Erickson, CMO of Picnic. “Picnic and ContekPro share a vision of innovating for the future of foodservice. Combining the quickly built modular kitchens with the Picnic Pizza Station, a new restaurant can be opened 50% faster than before. This means ghost kitchens, sports and event venues, and QSRs can be up and running in record time and saving money from day one.”

“ContekPro provides an alternative to traditional brick and mortar kitchens. The food service industry is changing, customer demands are evolving, and we entered a new construction era after the pandemic. We manufacture turnkey products that embrace modern operators and offer cost-effective and environmentally-sound options,” said Reda Attahri, co-founder of ContekPro. “The partnership with Picnic is a way to offer ready-to-use, end-to-end, high quality pizza concepts to ghost kitchens, stadiums, QSRs, amusement centers, or any location where speed to market, scalability, and profitability are important.”

How does the Picnic Pizza Station work?

The Picnic Pizza Station assembles pizzas autonomously and is completely customizable for each order–after a cook loads the dough, the Picnic station takes care of applying the sauce, cheese, fresh-cut pepperoni, and additional toppings. The finished pizzas can then move into the kitchen's ovens for cooking.

Each hour, the Picnic station can assemble up to 100 pizzas with 80% less food waste than traditional makelines. The Picnic technology allows for integration with a kitchen's point-of-sale (POS) equipment and mobile ordering platforms.

The Picnic Pizza Station is NSF and ETL/UL certified and is supported with cloud-based software and over-the-air firmware updates.

The customer roster for the Picnic Pizza Station includes managed foodservice providers Compass, Chartwells, and Sodexo Live!, Domino's Pizza Enterprises, Texas A&M University, The Ohio State University, SeaWorld, and numerous regional pizzerias with new customers coming online weekly.

Robotics 24/7's featured Picnic Works in a round-up of pizza-making robots to watch this spring.

Article topics

Email Sign Up