Origin, developer of an open platform for additive mass manufacturing, is collaborating with Beth Israel Deaconess Medical Center (BIDMC) to find a solution for manufacturing COVID-19 test swabs. Over the last 2 weeks, Origin has quickly shifted its resources from being a 3D printer manufacturer to become a medical device manufacturer and has started production to address the shortage of COVID-19 test kit supplies.

BIDMC, an academic medical center affiliated with Harvard Medical School, selected Origin's 3D-printed test swab to be part of a clinical trial to evaluate it for efficacy and safety. Origin's 3D-printed swab passed a rigorous initial clinical evaluation for human factors, materials testing, and PCR compatibility, and we expect that full results of the clinical trial will be published shortly.

“The nation's need for rapid and widespread testing for COVID-19 has been hampered by a widespread shortage of the swabs needed for testing,” says Ramy Arnaout, MD, DPhil, associate director of the Clinical Microbiology Laboratories at BIDMC, who has led a multidisciplinary effort to resolve the shortage and is overseeing the clinical evaluations of 3D-printed swabs at BIDMC. “Innovations in 3D printing hold real promise for our collective efforts to diagnose and treat COVID-19, as well as to flatten the transmission curve.”

Origin's test swabs are considered an FDA Class 1 Exempt Device. In addition to BIDMC's clinical testing, Origin's swabs have gone through rigorous testing with the U.S. Army, Origin material partners, universities including UCLA and independent medical labs.

Origin designed the swabs using the nTop Platform to rapidly iterate many different versions for BIDMC to evaluate, allowing them to quickly hone in on the best design elements for clinical efficacy and patient comfort. Origin worked closely with its Open Material Network to identify the proper medical grade material and to quickly refine optimal processing conditions.

Origin is also part of a new industry consortium called PrintedSwabs.org, which is joining the efforts of the 3D printing industry with academia and medical enterprises to supply millions of 3D printed COVID-19 test swabs.

Origin Technology

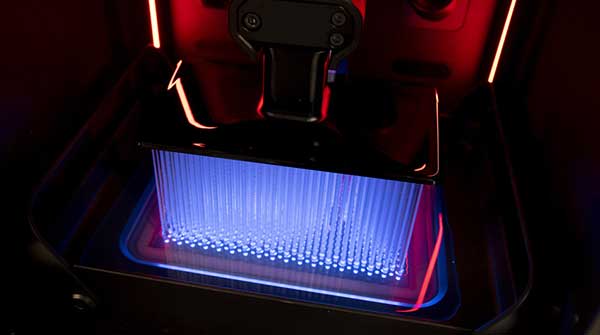

Origin's technology is a fit for this application because of its remote monitoring and control software, as well as its fine feature lattice capabilities. A single Origin One printer can print up to 1,500 swabs in a single print in under 8 hours. Origin's test swabs are a scalable solution. Complex, detailed geometries can easily be produced on Origin One and do not require any molds. The test swabs can be produced when needed, anywhere, with only a single material for the supply chain.

“Origin is proud to join together with teams of experts across technology, healthcare and academia to help fast-track efforts to get durable and safe medical devices in the hands of healthcare professionals,” says Chris Prucha, co-founder and CEO, Origin. “These are unprecedented times that require unprecedented measures. Given this, Origin has made the decision to focus its efforts solely on developing medical devices and PPE during this crisis. This shift happened quickly and under very difficult conditions, as San Francisco was the first city to order shelter in place.”

Other Origin COVID-19 Efforts

Origin is working on a number of other PPE projects. The company recently worked on an open source project to produce an ANSI-compliant face shield for DLP, SLA printers and SLS printers.

Origin also worked with Stanford Engineering on a custom attachment for a full-face snorkeling mask, similar to the N95 mask, that will act as a swap-in-replacement for the snorkel tube: Pneumask: Reusable Full-Face Snorkel Mask PPE Project. The company has also been working with several open-source groups as a contributor on product development for other PPE equipment.

Availability of Origin Test Swabs

Origin's test swabs are available to order now.

Sources: Press materials received from the company and additional information gleaned from the company’s website.

About the Author

Press releases may be sent to them via [email protected]. Follow Robotics 24/7 on Facebook

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up