Robotics designers want to use fewer components in drive mechanisms, as well as a shorter chain and non-relevancy between each procedure, for higher accuracy and more efficient transmission, said HSOAR Precision Robotics.

Traditionally, gear and gear, gear and rack, worm and gear, and screw and nut are the main related mesh mates in overall transmission, according to the Shanghai-based company. Motion-control errors will be transmitted and accumulated from the power input side to the output in accordance with the speed reduction ratio, said HSOAR.

Avoiding transmission errors

Transmission errors will also directly influence both the threads in lathe machining and gears, hobbling processing, said HSOAR.

The transmission precision of planetary gearbox refers to the influence of the precision of each link in the transmission chain on the accuracy and consistency of the movement of the end effector.

HSOAR listed the following the common transmission accuracy errors:

- The error of transmission parts has a major influence on the transmission accuracy of equipment.

- The error of a mated component and its assembly quality has an obvious influence on motion accuracy.

- During the operation of transmission parts, deformation is inevitable because of heat and stress, affecting the final accuracy.

So the longer the transmission chain, the greater the impact on the accuracy, said the company.

Precision Cycloidal Ball Reducer specs

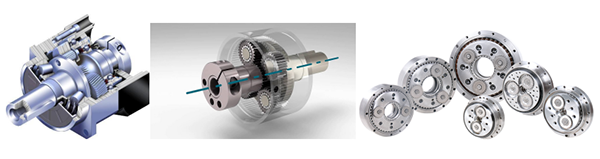

HSOAR recommended its Precision Cycloidal Ball Reducer gearbox, which does not actually include any gears. The company said that its mechanism, which uses full-contact rolling steel balls, can provide “outstanding” accuracy and repeatability. HSOAR claimed that it is a “significant advance” over the 100-year-old traditional gear drive.

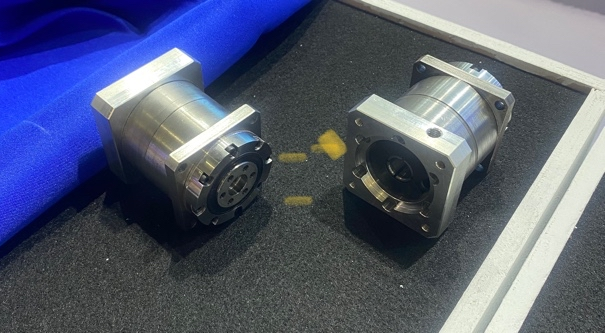

HSOAR said its Precision Cycloidal replacement for planetary gearbox SD-BRG60 has the following features:

- Accuracy: ≤2 arc min.

- Torsional rigidity: 6 N.m/arcmin; all steel ball transmission elements engaged in eccenric motion at the same time to absorb impact evenly

- Reduction ratios: 5, 9, 10, 15, 20, 36, 41, 53, 60 for SD-BRG60F(S)

- Rated and maximum input rotation speeds: 3,000 rpm, 6,000 rpm

- Weight: 1.2kg (2.64 lb.)

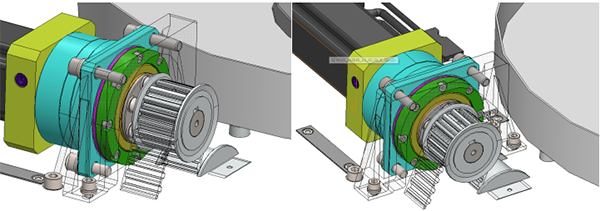

The company also provided an example application:

HSOAR said it has been authorized to provide the Precision Cycloidal Ball Reducer gearbox to world's top robot brands, and it welcomes inquiries.

Article topics

Email Sign Up