At the Formnext event yesterday in Frankfurt, Germany, Markforged Inc. announced the release of new Simulation features for its additive manufacturing software. Simulation is available as a free trial until April 2023 and as a paid subscription thereafter, said the company.

As both 3D printing and simulation software move from prototype to production, the complementary technologies promise to save manufacturers time and money previously spent on design/print/break testing cycles, according to Markforged. The Watertown, Mass.-based company said Simulation enables virtual testing of materials and designs for demanding applications.

“This conversion of hardware, software, and materials comes down to confidence,” said Doug Kenik, principal product manager at Markforged. “Without Simulation, additive manufacturing won't be able to scale as promised.”

“This is especially true in FFF [fused filament fabrication], where knowing the strength, stiffness, and performance—and how tight the tolerance is—can speed up the workflow,” he told Robotics 24/7. “With its acquisition of Teton Simulation Software, Markforged can now answer the question of how strong continuous-fiber composites are.”

Simulation to speed parts design, testing, production

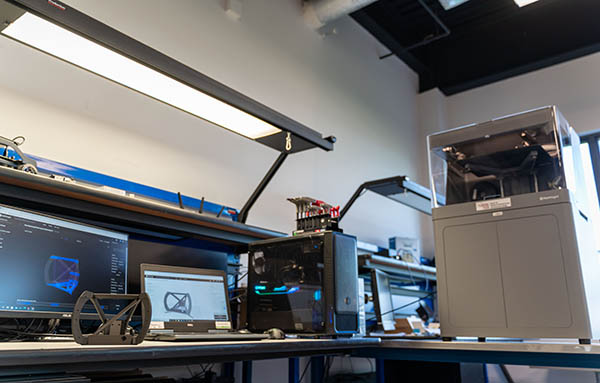

Markforged said more than 10,000 customers in over 70 countries use its Digital Forge platform, which combines the Eiger software interface, advanced materials, and 3D printers to produce robust metal and composite parts.

Unlike traditional software tools that need specialized expertise and time-consuming analysis, Simulation is designed for additive manufacturing and works within the Eiger “slice and print” workflow, said Markforged.

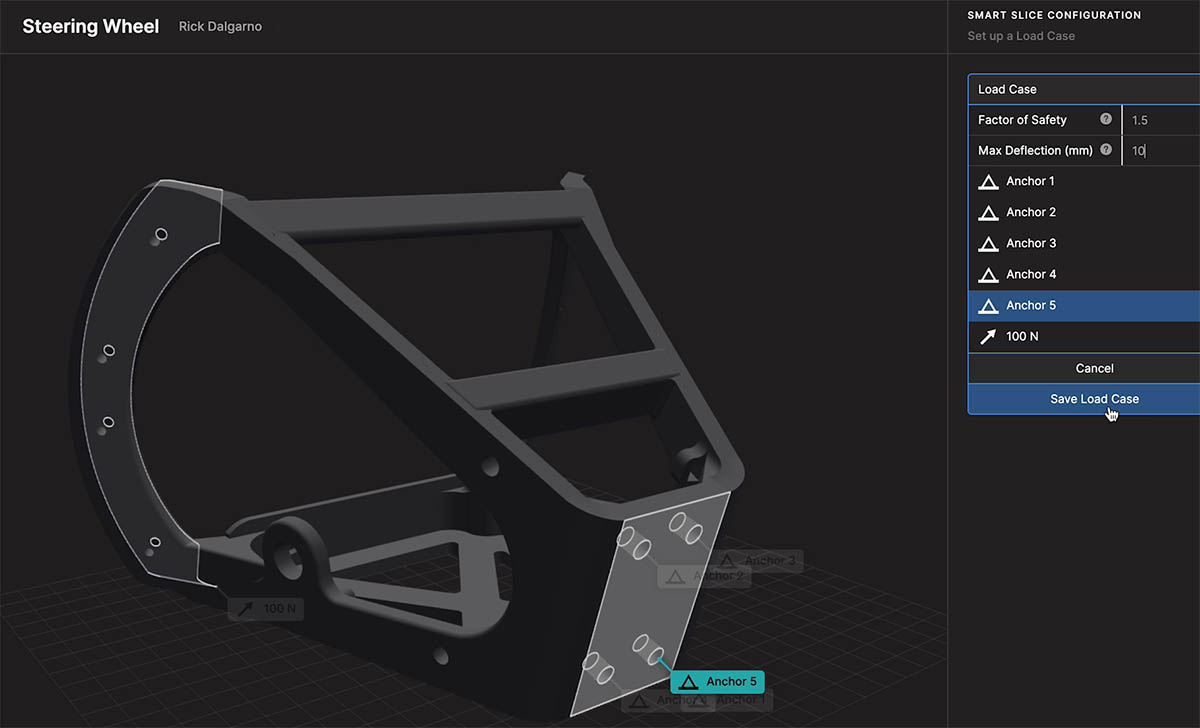

Any user can validate part strength and stiffness through virtual testing by identifying anchor and load surfaces and then entering values for loads, factor of safety, and maximum deflection, the company said. With Eiger, Markforged customers can work with simulation tools and generative design to create a range of options based on their unique priorities of cost, print time, materials, part fatigue and lifespan, and environmental factors, Kenik noted.

Users can then automatically determine print settings for floors, walls, infill, and fiber reinforcement.

“As a cloud-first platform, Eiger has elastic compute and allows users to start setting up a problem, come up with a solution between 30 seconds and 20 minutes, and validate and optimize it,” said Kenik. “They can also monitor the health of the fleet with data streaming everywhere.”

“Simulation enables our customers to adopt The Digital Forge deeper into their manufacturing operations by replacing more mission-critical tooling and end-use metal parts with validated and optimized, 3D-printed advanced composite parts with continuous fiber reinforcement,” stated Shai Terem, president and CEO of Markforged. “Cloud-based software innovation like Simulation is core to our mission to bring industrial part production to the point of need.”

Larsen Motorsports takes the wheel with Markforged

“We take a jet engine and put it in a car that can reach 275 mph in 5.7 seconds,” said Brian Tocci, director of operations at Larsen Motorsports. “We do research with Northrop Grumman and Siemens and workforce development and training with Florida Tech students in 27,000 sq. ft. Racecars are our platform for intensive testing in additive manufacturing, robotics, and biofuels.”

“For example, we just finished a project where we used additive manufacturing to print gaskets for aviation biofuel, which reacts differently from Jet A fuel,” he said. “We used low-cost 3D printers to test a wide range of materials that we soaked in these biofuels. Every week, we take measurements, then at six months and a year to see how they're reacting. We take the top three to run in a test cell to see how they can run for an hour or more.”

Larsen Motorsports found that stock aluminum steering wheels for its vehicle were shaped for larger hands than those of its award-winning driver, Josette Roach. This put safety and performance at risk, noted the Palm Bay, Fla.-based company.

Larsen used Markforged's Simulation to design and print a continuous carbon fiber-reinforced Onyx steering wheel strong enough to replace aluminum.

“Rather than print parts and test them, we can simulate reinforcements in 3D printing software,” Tocci said. “In this case, we did 50 to 60 simulations before we printed one part. Now, the steering wheel is equivalent to aluminum in strength and fully customizable to our six drivers in total.”

“Instead of purchasing steering wheels from a vendor, waiting three to five days for shipping, and then requiring a day to make modifications, we can cut down the time by at least a day and have a stronger part,” he noted. “Even before a skilled fabricator's time for customization, the material costs are the same.”

“We've shown on average a 50% to 90% reduction in iteration cycles using simulation technology, as well as 50% material savings and more throughput,” said Kenik.

Tocci added that Markforged's support team members were helpful in explaining the Simulation software. “They'd help you understand what's happening, such as how to reinforce an area without adding material,” he said.

Looking ahead, Tocci said he can envision using Markforged's 3D printers and Simulation to optimize brake pedals and throttle levers with digital twins from Siemens.

“We can also help lead to educate people how to use 3D printers,” he said. “The next generation is learning how to optimize printing using Simulation.”

Simulation available, on display

Other industrial use cases for Markforged's Simulation include jigs, fixtures, and tooling, said Kenik. “If you can validate designs with Simulation and connect a fleet of printers globally with Blacksmith, you could take the time down from weeks to hours,” he said. “The opportunity for distributed manufacturing is insane.”

From not having to store spare automotive parts to the ability to share updated, digitally signed files, manufacturers and repair shops could bypass supply chain breakdowns, said Kenik.

“We're not going to cut out all iterations, but going from 10 to two—this is where everyone wants to go,” he said.

Simulation is available worldwide today as a free trial for anyone with a Markforged Eiger account. The company will present on “How simulation, in-process monitoring and inspection will drive the future of additive manufacturing” at Formnext on Friday, Nov. 18 at 11:40 a.m. CET in Hall 12, Stand E38.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up