Locus Robotics yesterday said it has enhanced its mezzanine management capability to optimize order-picking management for multi-level mezzanines and vertical warehouses. The Wilmington, Mass.-based company said the changes are designed to increase productivity, flexibility, and maximum throughput for e-commerce order fulfillment.

“With Locus Mezzanine Management, operators have optimal control over order management and worker productivity, regardless of the number of mezzanine levels,” said Sophie Pagalday, director of product marketing at Locus Robotics. “This powerful tool optimizes each task for throughput and productivity with smart, in-level task/pick clustering and directed pick and pass.”

Warehouse operators look up

As order volumes continue to skyrocket, warehouse operators have quickly outgrown floor space in today's fulfillment and distribution centers. To stay ahead of demand, many warehouse operators are choosing to go vertical instead of building new buildings, said Locus. However, efficiently managing workflow and personnel in multi-level operations has become a management challenge, according to the company.

“Nearly 30,000 warehouses will be added over the next five years to help with the ongoing shifts in consumer buying trends and changing supply chains,” said Ash Sharma, senior research director at Interact Analysis. “But that alone will not be enough to cope with growing SKU counts and retailers' desire for better stock availability.”

“This mezzanine-style approach is finding strong adoption around the world as a way to easily provide additional warehouse capacity at existing facilities,” he observed.

Locus adds orchestration features

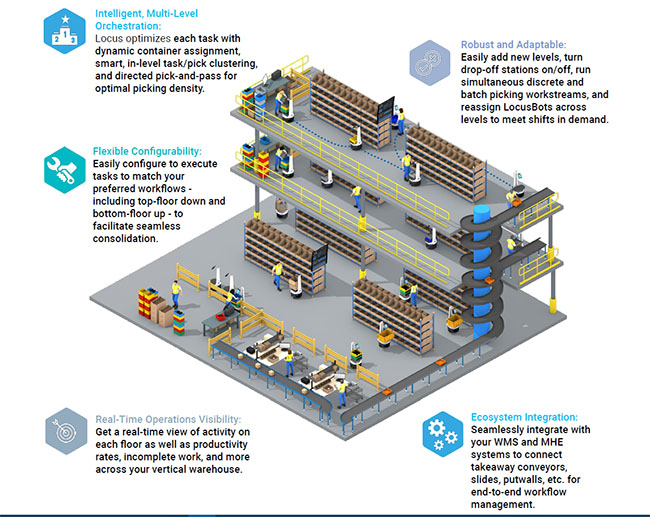

Locus Robotics claimed that it can intelligently orchestrate tasks across multiple levels or mezzanines in very large centers, optimizing workflows and order consolidation for maximum throughput. The company said its workflow optimization engine directs LocusBots and workers to follow the most efficient order-picking sequence.

Locus said the new features include the following characteristics:

- Intelligent, multi-level orchestration: Users can optimize each task for throughput and productivity with in-level task/pick clustering and directed pick-and-pass.

- Flexible and adaptable: Operators can easily add new levels, turn drop-off stations on/off, run simultaneous discrete and batch picking work streams, and reassign LocusBots across levels to meet shifts in demand.

- Configurable: Customers can configure Locus to execute tasks to match their preferred workflows—including top-floor down and bottom-floor up—to facilitate consolidation.

- Real-time visibility: Users can access a real-time view of activity on each floor as well as productivity rates, incomplete work, and more across your vertical warehouse.

- Ecosystem integration: Companies can connect their warehouse management systems (WMS) and material handling equipment (MHE) such as takeaway conveyors, slides, and putwalls to Locus for end-to-end workflow management.

Locus Robotics offers autonomous mobile robots (AMRs) that can collaborate with human workers to improve piece-handling productivity and integrate into existing warehouse infrastructures without disrupting workflows. The company this year joined the Inc. 500, ranking No. 428.

Article topics

Email Sign Up