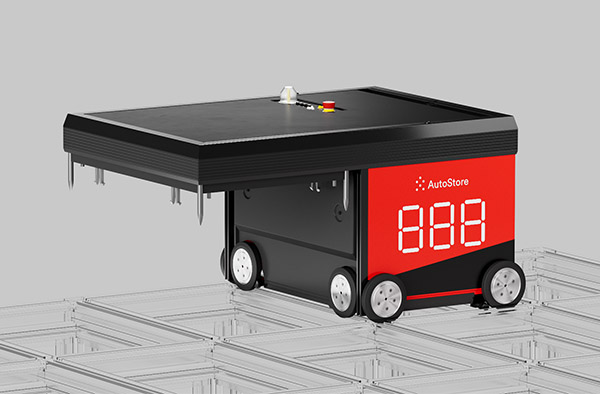

AutoStore yesterday announced the R5 Pro Robot, which it said is the latest version of its “field-proven” R5 robot. The Nedre Vats, Norway-based company said it designed the new robot to address the growing demand for large, high-throughput systems in e-commerce operations.

“The R5 Pro offers an edge by augmenting productivity per robot during extended operations, optimizing space usage, and reducing the total cost of ownership, ultimately enhancing the customer experience while boosting profitability,” stated Carlos Fernandez, chief product officer at AutoStore.

Founded in 1996, AutoStore said it develops automated storage and retrieval systems (ASRS) to help businesses maximize order-fulfillment efficiency. The company offers both hardware and software and said its AutoStore technology is interoperable with third-party systems.

AutoStore said its qualified systems integrator partners have designed, distributed, and installed more than 1,250 systems in 50 countries. The company has offices in Norway, the U.S., the U.K., Germany, France, Spain, Italy, Austria, South Korea, Japan, Australia, and Singapore, as well as assembly facilities in Poland.

AutoStore touts R5 Pro features

The R5 Pro is intended for companies running multi-shift operations at scale, said AutoStore. It listed the following features and potential benefits of the R5 Pro Robot:

- Enhanced productivity: By deploying the R5 Pro at a large AutoStore site, customers can reduce the number of robots required on the same grid by up to 15% when compared to using the R5 Robot, enabling better routing and enhanced system efficiency, asserted AutoStore.

- Continuous operations: The R5 Pro uses an LTO (lithium-titanium oxide) battery, providing rapid charging and improving individual robot availability during multi-shift operations, the company claimed.

- Space and cost optimization: The LTO battery requires up to 86% fewer chargers, freeing up warehouse space, accommodating additional SKU storage, or reducing the required footprint. AutoStore added that customers can “achieve significant cost savings related to electrical infrastructure.”

“The introduction of the R5 Pro improves both our market position and the value proposition for customers managing very large systems and high-throughput operations, typically characterized by extended operating hours and a substantial robot count,” said Fernandez.

Boozt expects a boost from new robots

“As a leading e-commerce company, we are always looking for new ways to optimize warehouse operations,” noted Tobias Sjölin, chief technology officer for fulfillment and logistics at Boozt, an apparel retailer and prominent AutoStore customer.

“We are excited about the R5 Pro, the latest addition to the AutoStore R5 series, which will bring tangible benefits to customers with large AutoStore systems that require speed,” he said. “Being able to reduce charging time during multi-shift operations offers great potential for improved productivity.”

“The projected higher productivity per robot means we would need significantly fewer robots and chargers to achieve our required throughput – and also enable us to fit more SKUs within our existing Grid,” Sjölin said. “But in the end, it’s all about the total cost of ownership. All these incremental savings add up over time and allow us to remain competitive.”

Article topics

Email Sign Up