Getting started with managing robot fleets can be difficult for busy developers and facilities operators. InOrbit Inc. today launched a Free Edition of its cloud-based robot operations, or RobOps, software. The Mountain View, Calif.-based company said it will help businesses scale their fleets and free them to focus on their unique differentiators.

“When we've talked to customers, many think they're going to develop RobOps software in-house, but many times, they don't know how much work that is,” said Florian Pestoni, co-founder and CEO of InOrbit. “But if they're freed from spending the next six months to three years on development, they can focus on building or using the robots.”

“We've been thinking about a free edition for some time,” he told Robotics 24/7. “When we first launched the product, we offered free access for the first five robots for one year. A part of our motivation was to make it as easy as possible for startups to use it.”

InOrbit explains free features

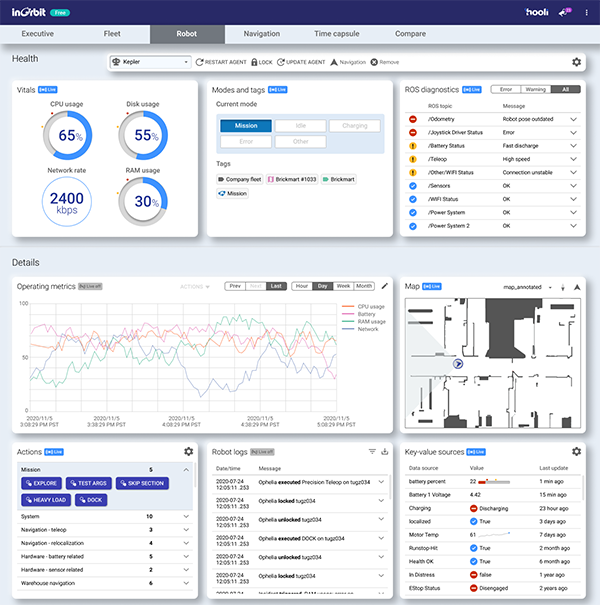

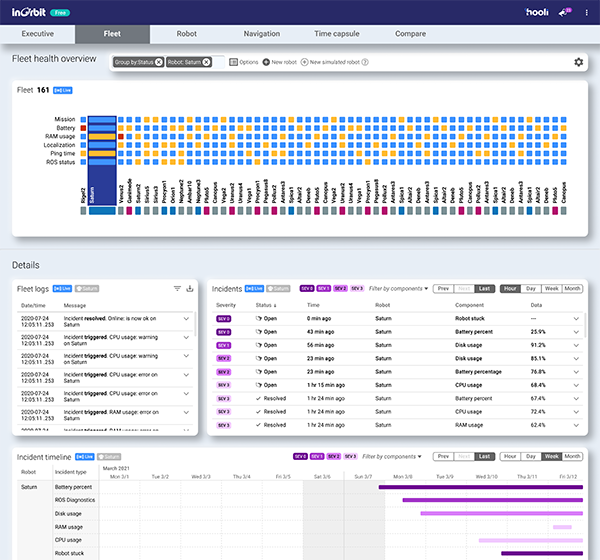

InOrbit said its data platform enables robotics developers and operators to “master the four O's of robot operations: observability, operation, orchestration, and optimization.” The multi-cloud system provides secure, real-time analytics and data collection, robot performance monitoring (RPM), incident response, and root-cause analysis, the company said.

“We've come a long way. We now have larger customers with more advanced needs,” said Pestoni. “We've spent a lot of time talking to engineers and other people at these companies. We know there's a need to remove friction and allow interoperability, but they're not fully there yet.”

“We’ve seen too many robotics companies waste precious time reinventing the wheel,” he stated. “With InOrbit Free Edition, we are helping companies address common robot operations problems without having to worry about entering a credit card. And unlike other limited time trials, Free Edition supports an unlimited number of robots for free – forever.”

With bigger customers buying a more fully featured version of InOrbit's platform, what do Free Edition users get?

InOrbit Free Edition enables access to the end-to-end platform infrastructure, including the robot-agnostic InOrbit Agent, Adaptive Diagnostics, secure messaging infrastructure, and the InOrbit Control personalized dashboard.

It also includes observability features such as vital robot analytics and diagnostics, as well as the ability to track a robot’s position on a map in real time, the company said.

In addition, users can define, detect, and respond to incidents through one-click actions within the app or through included Slack integration, said InOrbit.

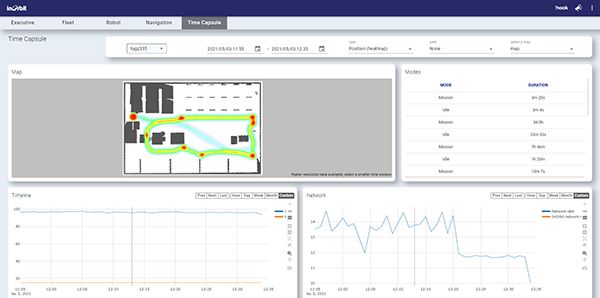

“We want to see more robots out in the world, but we're not giving the whole farm away,” Pestoni said. “When a robot first leaves the lab, a lot of things can go wrong. InOrbit Standard Edition has more advanced functionality for root-cause analysis, integrations, real-time teleoperation, and other navigation, as well as the recently launched Time Capsule.”

Time Capsule delivers actionable data

Time Capsule is a software-as-a-service feature that gives robot users the ability to “turn back time” to see where failures occurred.

“Before Time Capsule, users had to download data, put it into a simulation, and try to glean information from it. You really needed a Ph.D. in robotics,” said Pestoni. “For people in production, this has become critical at scale. They need to understand incidents in the real world. If they can get a shorter path to valuable insights, the better you can make the robot operations.”

“For example, one customer was operating at multiple locations, but at this one location, a robot ran into a problem every day at the same time,” he recalled. “It couldn't figure out the problem at first, but we eventually discovered that the sun shone through a skylight onto something reflective that tripped up the lidar at a certain of time of day. The customer tried to recreate the problem at night when no one was there, but it needed to go back to that precise moment in time.”

“Another customer has used Time Capsule differently from what we had originally intended for it in production,” Pestoni added. “It's about to launch a new product and is in the final stages of refinement. It's running a lot of tests at scale and has found Time Capsule useful for that. It's still in a semi-controlled environment—not quite the lab or field—but we learned that helping with final quality assurance is yet another use case.”

Interoperability and managing complexity

While relatively few warehouses today have many robots, let alone multiple types of robots from multiple vendors, some large robotics users are concerned about the need for interoperability in heterogeneous environments. InOrbit is a founder of the Robot Operations Group and recently joined the standards efforts at MassRobotics, an organization devoted to growing the Massachusetts robotics ecosystem.

“As a member, we now support the new MassRobotics interoperability standard as part of InOrbit and have made open-source contributions,” said Pestoni. “Other standards are coming soon.”

“One of the roles we took on is to share information and raise awareness,” he said. “If we want this future with lots of robots doing the heavy lifting, we believe that this idea of interoperability and orchestration of all of these robots in real time is going to be critical.”

“People need to understand that in advance. Some people start with one vendor, to hundreds or thousands of robots from multiple vendors,” Pestoni continued. “You can't have spreadsheets or three to seven monitors—you need something else.”

“What's fascinating to me is that some very large enterprises use software like ERP [enterprise resource planning] and WMS [warehouse management systems] that they wouldn't dream of doing manually or in isolation,” he said. “We're trying to help people understand that as a developer or adopter of robotics, you need a better way to manage all this complexity.”

“If you're still doing things with charts and forms versus someone using real-time decisions for robots, I think I know who's going to win,” said Pestoni. “It may not be this year or next year. We saw this with next-day delivery, which we now take for granted. Its use case evolved through software, robotics, and automation, and it's impossible to do any other way at scale.”

Users can reallocate time with InOrbit

Robotics companies that have used InOrbit said they do not have to dedicate valuable engineering time addressing cloud infrastructure, data collection, analytics, and incident management. As a result, they can focus their development efforts on their specialized robots.

“The InOrbit platform is a natural fit for our RoomieBots because we can put our focus in the research and development of the hardware capabilities and delegate software management to InOrbit,” said Aldo Luévano Ibarra, CEO of Roomie, a startup developing commercial humanoid robots for Latin American service markets. “The main advantage is that we don’t need to worry about the software capabilities in the product’s evolution, letting us avoid capital-intensive investment for software development to receive the latest technology.”

Robotics trends include better data

Looking ahead, Pestoni said that he expects robots to become more capable because of advances in data collection and analysis.

“I see more and more roobts taking on specific tasks and doing better and better,” he said. “See what Ambi Robotics is doing—[Stanford University's] Ken Goldberg worked on the technolgy for 20 years, but such levels of picking became a reality only in the past year or two. From there, it's not hard to look at practical applications, such as picking up children's clothing from the floor.”

“But it's better to first focus on tasks that can be done at scale,” said Pestoni. “John Deere recently acquired Bear Flag Robotics. Agriculture is another great application just becoming possible today, in comparison with humanoids, which may take a while longer.”

“But robots do things that people cannot or that weren't possible before,” he said. “What excites me is that mobile robots are data-collection machines. I'm seeing a much greater appreciation for the need for usable data that can lead to insights. There's a realization that a robot isn't a lathe or a machine you put in a corner. Data is super critical, which is what we've been preaching all along.”

With a growing number of software and robotics-as-a-service (RaaS) providers, how does InOrbit see the market growing and competing?

“I come from the cloud world, and I welcome new companies,” Pestoni said. “In the early days, you could do one use case from soup to nuts, but now it's an ecosystem. No one vendor can control everything. I see plenty of room for specialization and differentiation.”

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up