Robotics can help augment human capabilities and alleviate staffing shortages, but only if it is easy enough to use. Hexagon AB last week announced HxGN Robotic Automation, control software designed to enable non-specialists to program industrial robots to perform fully automated quality inspections.

“Manufacturers are facing disruptions to their supply chains because of trade conflicts, the COVID-19 pandemic, and rapid innovation,” said Stephen Graham, president of metrology and production software at Hexagon’s Manufacturing Intelligence division. “For example, electrification is changing the automotive industry. Companies need faster time to market in the face of new entrants like Tesla.”

Manufacturers can use the new platform to equip greenfield factories or retrofit existing production lines with autonomous optical inspection cells. Hexagon said this can accelerate time to market by eliminating bottlenecks while providing more complete data direct from the production line.

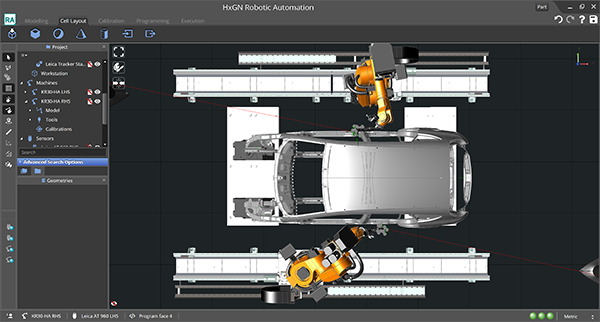

HxGN Robotic Automation offers offline programming

Metrology and robotics professionals typically need to devote significant time and attention to devise optimal inspection routines.

“Metrology engineers are not roboticists,” said Graham at a press conference. “We want to make robotics more accessible.”

HxGN Robotic Automation allows them to do this in a single step, said Hexagon. Staffers can now develop the program offline, away from the production line with a digital twin. They can then deploy a robust program to the robotic cell, the company said.

The software is built on open design principles, claimed Hexagon. What does this mean?

“HxGN can interface with different hardware and software components,” explained Juan Mora, product manager at Hexagon Manufacturing Intelligence. “We're robot-agnostic and can coordinate different systems to collect the data, which is then sent to software for analysis. It can be different platforms.”

“Being open means we can integrate with existing and new hardware and software and custom processes,” he told Robotics 24/7.

The software supports Hexagon laser trackers, including its new HP-L-10.10, as well as Leica T-Scan and AS1 scanners. It can directly interface with FANUC and KUKA robots, while built-in postprocessors enable the robot controller to work with a wide range of third-party robots.

“Speed, robustness, and scalability are all extremely important,” Graham said. “Cells can be flexible in terms of their size and the number of robots. We can also provide turnkey inspection cells optimized to work with Hexagon sensors.”

Future versions will support the HxGN SLS structured light scanner and third-party sensors, according to Hexagon.

Hexagon supports real-time optimization

Demand is growing for vertical integration to consolidate quality control across diverse supply lines, said Hexagon. It added that its new software can work with everything from small to extra-large part sizes.

HxGN Robotic Automation is also designed to work with simple, single, fixed robot cells, as well as complex cells with multiple sensors and robots on rails and tables.

By enabling measurement data to be automatically captured at the source and used for real-time optimization, the technology embeds quality assurance in the heart of production, said Hexagon. This allows quality professionals to multiply their quality assurance efforts, driving consistency and consolidating metrology data throughout production lines. It can also free up staff time for other tasks, such as data analysis.

In addition, offline programming makes it possible to repurpose or hone metrology cells with minimal production downtime, Hexagon said. Manufacturing operations can be more agile and use new cell-based models to achieve product customization and speed without sacrificing the efficiencies associated with volume production, said the company.

Škoda Auto halves inspection times

Manufacturers such as automaker Škoda Auto a.s. in the Czech Republic are already using the software and benefiting from it, said Hexagon.

“We've had robotic inspection cells for some time, but in the past, we always had two systems for programming—on for the robot arm, and the second for the measuring points,” said Jehlička. “It was difficult to have one specialist for both.”

“Each new [vehicle] model has 70 to 80 new parts, so there's not a lot of time to test with real parts,” Jehlička noted. “Now, with offline programming, we can measure the part first and make sure it's working and answer questions from production about dimensions.”

“We have reduced the time required to program robotic inspection from several days to just four hours using the new software, so we can be ready and waiting to inspect a new vehicle as soon as we want to begin production,” said Martin Jehlička, chief of the measurement center at Škoda Auto. “Automation and Hexagon’s high-speed, laser-scanning systems have already halved the inspection time for parts and sub-assemblies.”

“We make one car per minute, so we have to be 100% sure that all systems are OK,” he said. “Installing these automated inspection cells on the production line is fundamental to our Industry 4.0 strategy of making data available and actionable so quality trends can be identified quickly, or in some cases automatically corrected.”

Flexibility for future-proofing factories

HxGN Robotic Automation provides quality professionals the flexibility to use the most appropriate sensors and help future-proof factories with real-time, inline metrology, said Hexagon.

The resulting metrology data can also improve design simulations by enabling manufacturers to predict the as-manufactured performance of products at the design stage. For example, they could anticipate residual stresses that could be caused during casting.

Rich, in-line metrology data could allow future machine learning systems to optimize designs, parts, and processes, leading to increasingly autonomous, self-correcting production lines, Hexagon said.

“Automating inspection is vital to enable OEMs to consolidate quality across increasingly diverse, complex products and processes,” said Graham. “Truly smart manufacturing needs swift, accurate, and accessible measurement data. The factory of the future will use this data for responsiveness.”

“But many robotic inspection systems are costly, complex, closed systems that are incompatible with manufacturer’s chosen tools and inaccessible to non-specialists,” he noted. “HxGN Robotic Automation is built around openness, so that manufacturers can swiftly and seamlessly future-proof entire manufacturing lines for robotic inspection.”

About Hexagon

Hexagon said it is a global leader in sensors, software, and autonomous systems. The Stockholm, Sweden-based company said it can improve efficiency, productivity, and quality across industrial, manufacturing, infrastructure, safety, and mobility applications. Hexagon has about 20,000 employees in 50 countries and net sales of approximately €3.8 billion ($4.52 billion U.S.).

“Hexagon supports global manufacturing—95% of all cars, 90% of aircraft, 75% of all smartphones, and 80% of orthopedic implants,” said Graham.

The Hexagon Manufacturing Intelligence division in North Kingstown, R.I., takes data from design and engineering, production, and metrology to make manufacturing smarter, more scalable, and more sustainable. It said it supplies technologies for connected and autonomous systems to companies such as Volkswagen and Boeing.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up