Warehouse inventory management service provider Gather AI recently announced two new capabilities for its systems: location occupancy and inferred case counting.

The company, which produces machine vision AI software for inventory-monitoring drones, said its new capabilities enable warehouses to get automated, digitized counts and location utilization reports, unlocking higher on-time shipment rates while reducing dedicated counting labor.

“Our mission is to bring unprecedented real-time inventory insights to warehouse operators,” said Sankalp Arora, Gather AI CEO and co-founder. “Our computer vision and AI analyze inventory images offering warehouse operators access to a richer source of information than barcodes. Our new inferred case counting and location occupancy capabilities push the art of what’s possible while solving for error-prone, labor-intensive tasks for our customers.”

Gather recently raised $17 million series A to scale operations and attract customers.

Opportunities to improve labor efficiency, space utilization

With Gather’s robotics-as-a-service (RaaS) drone systems, warehouses can scan up to 900 pallets per hour. Off-the-shelf drones fly around warehouses autonomously, taking pictures of each location. Then, Gather’s AI software analyzes the pictures, reading multiple barcodes, text, and detecting empty locations.

Gather AI’s new offerings include:

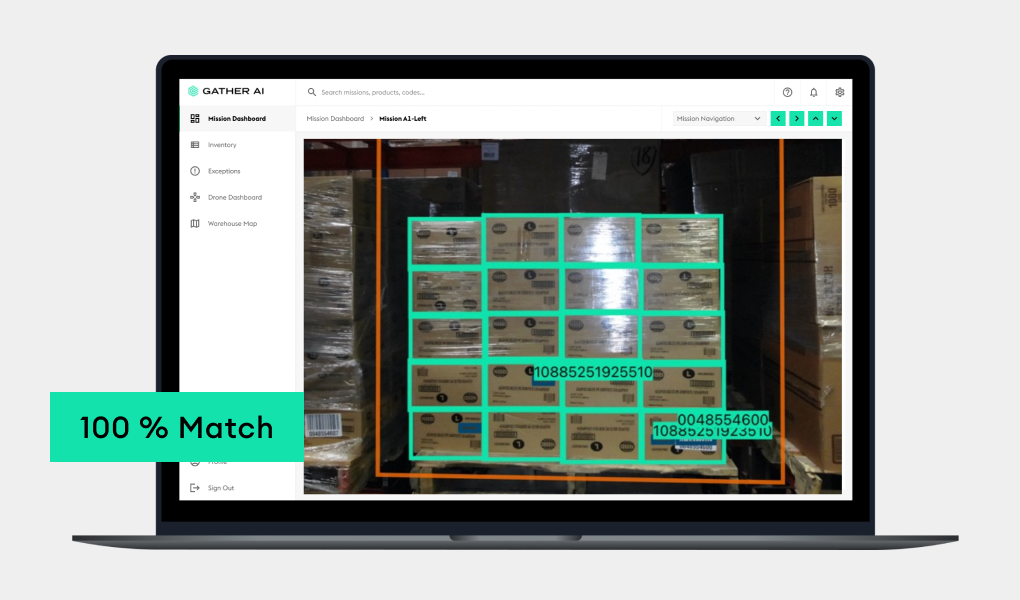

- Inferred Case Count: Using this capability, warehouse operators can reduce the time spent on manual counts by 90%, Gather said. Computer vision and AI compare information extracted from images to estimate the number of cases on a pallet with what’s stored in the warehouse management system (WMS). Pallets with few cases are flagged so they can be replenished before items run out and shipments are missed. Warehouse operators can prioritize labor by having people count only the pallets that do not match what the WMS expects.

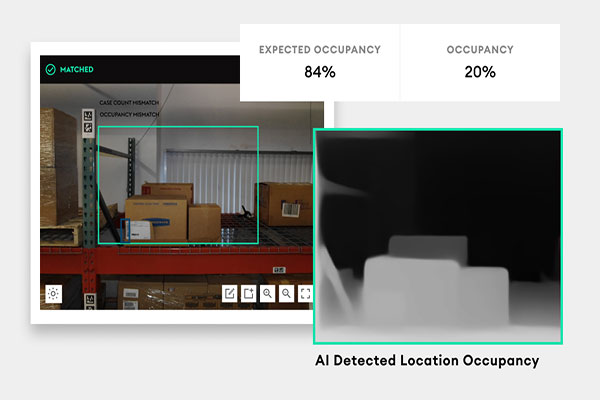

- Location Occupancy: This capability lets warehouse operators know where to consolidate pallets, increase space utilization, and improve fixed expense efficiency, Gather said. Computer vision and AI read images to measure the space available on a pallet. The system will then identify consolidation opportunities.

With Gather’s newest capabilities, its systems will be able to show inferred case counts for full and partial pallets, as well as location occupancy percentages on the customer web dashboard. Gather said these features can reduce the time and labor of verifying case counts and help warehouses find space to consolidate inventory, avoiding honeycombing.

“Several customers require us to count cases as part of our cycle counting program,” said AJ Raaker, director of warehouse development at 3PL company Taylor Logistics Inc. “Using Gather AI's drone inventory monitoring and the inferred case count feature is 87% more efficient than having our team do physical cycle counting. The efficiency gain enables our team to prioritize revenue-generating direct labor activities.”

Want to learn more about data management in robots? This article was featured in the September 2024 Robotics 24/7 Special Focus Issue titled “Robots as mobile data platforms.”

Article topics

Email Sign Up