Collaborative robot arms can gain additional degrees of freedom with certain configurations. Last week, Festo Corp. said it has developed a UR+ certified four-axis system for cobots from Universal Robots A/S. The new system adds more axes of motion beyond the UR robots' six axes and comes ready to install, said Festo.

Mississauga, Ontario-based Festo makes pneumatic and electromechanical systems, components, and motion-control systems for process and industrial automation. The company is celebrating 50 years of providing optimized systems in the U.S. It claimed that it has provided manufacturers with innovations that deliver higher-performing, more profitable automated manufacturing and processing equipment.

In addition, Festo Didactic Learning Systems and its partners prepare workers for current and future manufacturing technologies through advanced technical and industrial education.

Festo adds axes to cobots

Collaborative robot applications are intentionally simple to configure and operate. This multi-axis system is no different, said Festo. No programming is involved in setup, and no additional programmable logic controller (PLC) is required, it added.

End users can configure multiple axes through Universal Robots' human-machine interface (HMI). They can simply set position, speed, and acceleration on the HMI or, with the URCap toolbar, move the axes in manual mode to configure motion.

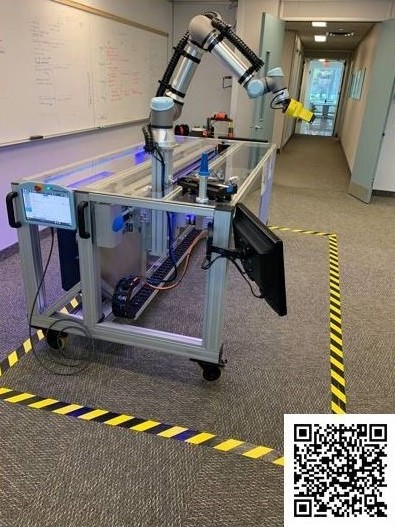

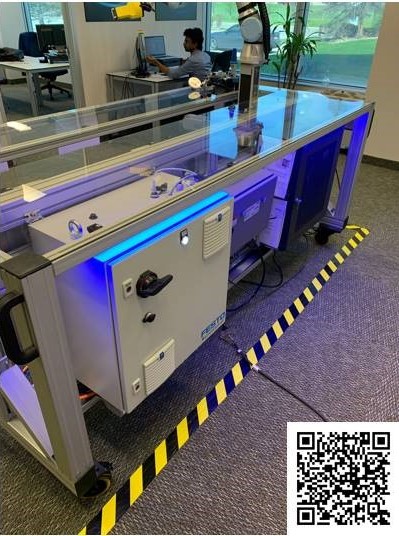

Festo said its multi-axis system features the Festo Motion Control Package (FMCP) for UR, which is a complete motion-control panel for up to four-axis motion. The FMCP is fully integrated with the UR cobot control panel and HMI and features a UR safety I/O and communications interface.

Uses for more axes of motion

In addition to a seventh axis used for linear transfer, the FMCP can control turning tables, automatic storage systems, conveyors, and transfer tables, all under the UR umbrella. The FMCP has extra space within the panel for future expansion and brackets for wall mounting, which reduces its footprint.

The seventh axis can also extend the range of action for a UR cobot in applications such as palletizing and machine tending.

Festo EGC belt-driven or ball-screw linear axes come equipped with a cobot mounting plate. The EGC has an energy chain for cable management and a servo motor optimized for performance.

Standard EGC axes are available in lengths of up to 8 m (26.2 ft.), with up to 10 m (32.8 ft.) axes available by request, said the company.

Festo also offers a wide range of grippers such as vacuum, mechanical, and its Magswitch magnetic grippers, including the cobot smart gripper E30 cobot smart gripper. Automatic tool changers are also available.

Article topics

Email Sign Up