Eureka Robotics today announced that it has developed a proprietary force-feedback technology that can make industrial robots almost as nimble and sensitive as human hands. The company and its Dynamis software spun out of research at Nanyang Technological University (NTU) Singapore. Eureka Robotics said its technology enables robots to manipulate small and fragile objects that are millimeters in size without damaging them.

“Today, Dynamis has made it easy for anyone to program touch-sensitive tasks that are usually done by humans, such as assembly, fine manipulation, polishing, or sanding,” explained Pham Quang Cuong, an associate professor at NTU Singapore and co-founder of Eureka Robotics. “These tasks all share a common characteristic: the ability to maintain consistent contact with a surface.”

“If our human hands are deprived of our touch sensitivity, such as when wearing a thick glove, we would find it very hard to put tiny Lego blocks together, much less assemble the tiny components of a car engine or of a camera used in our mobile phones,” said Pham, who is also the deputy director of the Robotics Research Centre at NTU’s School of Mechanical and Aerospace Engineering.

NTU technology first seen in Ikea Bot

Mastering “touch sensitivity” and humanlike dexterity has been a holy grail for roboticists, said Pham. Programming force controllers is extremely complicated, requiring long hours to perfect the grip just for a specific task, he said.

Current robots in the market have either high accuracy but low agility, where robots perform the same movements repeatedly such as in a car factory, or low accuracy but high agility, such as robots handling packages of different sizes in logistics.

NTU scientists developed the force-feedback technology and demonstrated it with the “Ikea Bot,” which assembled an Ikea chair in just 20 minutes. The breakthrough was first published in the journal Science in 2018 and showed that a robot could match the dexterity of human hands in assembling furniture.

The Singapore university's NTUitive innovation and commercialization company incubated Eureka Robotics and has helped to speed its path to market. It said it followed the NTU 2025 strategic plan, which seeks to tackle some of the world's most pressing challenges with new technologies.

Eureka Robotics AI needs just one parameter

Known as “Force Sensor Robust Compliance Control,” the new software powered by Dynamis requires only a single parameter to be set – the stiffness of the contact, or whether it is soft, medium, or hard.

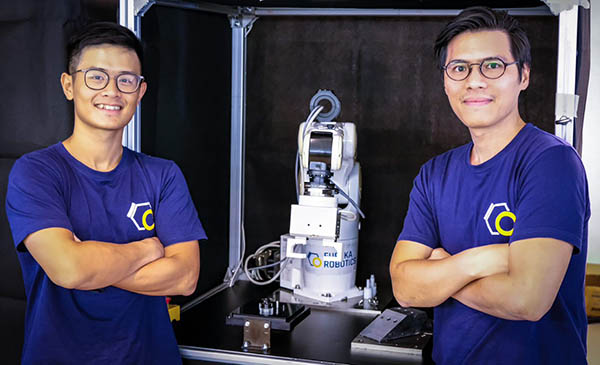

Pham developed the artificial intelligence algorithm with former Ph.D. student Dr. Hung Pham, now co-founder and chief technology officer of Eureka Robotics. This technology was further improved and was first deployed in Eureka’s custom-built robots, such as Archimedes. It can handle fragile optical lenses and mirrors with human-like dexterity and is now used by multiple companies worldwide.

Despite its simple setup, Dynamis can outperform conventional robotic controllers, which require an enormous amount of expertise and time to fine-tune, claimed Eureka Robotics.

Robotics engineers can use the technology to imbue robots with both high accuracy and high agility (HAHA) on a large scale, the company added. This could pave the way for industrial applications that were previously very difficult or impossible to implement, such as handling and assembly of delicate objects such as glass optical lenses, electronics components, or engine gears.

DENSO to offer Dynamis with force controller

Since the Ikea Bot and Archimedes, Eureka Robotics' founders said they have upgraded the software. It will be available for numerous industrial robots worldwide made by DENSO WAVE, which is part of the Toyota Group.

Clients purchasing the latest robots sold by DENSO will have an option to include Dynamis as part of the force controller, which reads the force detected by a force sensor on the robot’s wrist and applies force accordingly.

If too little force is applied, items may not be assembled correctly, while applying too much force could damage the items, noted Eureka Robotics.

“Due to its high basic performance and openness, DENSO robots are the preferred choice by companies and universities with advanced initiatives in the field of robotics,” said Hiroyasu Baba, FA/Robotics Business Unit Product Planning Department and manager of DENSO Wave. “NTU Singapore and Eureka Robotics have also been using DENSO robots for this reason.”

“Because of this relationship, joint development began naturally, and we were able to launch this product smoothly,” he said. “The technology, which will be installed in DENSO robots, is a technology for force feedback, which is becoming more and more important in the practical use of robotics. Thanks to the development capabilities of Eureka Robotics, the system is advanced, yet easy to use and light enough to be integrated into our standard robot controllers.”

To be equipped with the “Force Sensor Robust Compliance Control” capability, robots already running on DENSO WAVE’s RC8 controllers need only a simple software update from December 2021 onwards. Newly shipped RC8 controllers will come with the software available for activation.

Article topics

Email Sign Up