HP has teamed up with start-up software developer Dyndrite to create HP Universal Build Manager Powered by Dyndrite (UBM), which it describes as “a robust solution” for delivering CAD-to-print workflows for additive manufacturing.

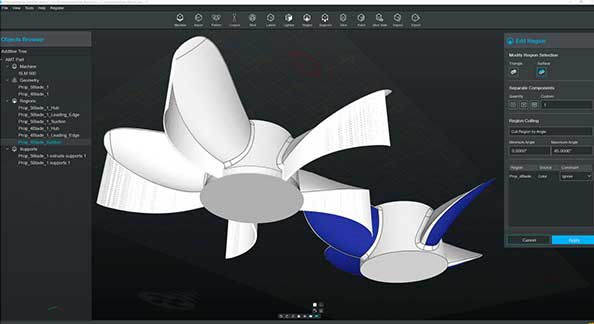

HP says UBM is an OEM- and process-agnostic tool and is supported by many leading vendors. It offers software tools for build preparation, CAD import, patterning, nesting, labeling, support generation and slicing. The Dyndrite engine supports NVIDIA Enterprise GPUs for computational acceleration. It uses Python as a scripting language, and offers various Python application programming interfaces for automation and workflow integration.

HP says this new build prep engine will help additive manufacturing engineers and technicians “improve productivity, efficiency and repeatability in their industrial additive production.”

“Additive manufacturing has always had incredible potential to disrupt the global manufacturing market, but has been limited by the focus on adapting traditional manufacturing software to address the problems that are unique to additive manufacturing,” said Ryan Palmer, global head of Software, Data and Automation, HP Personalization & Industrial Business in a statement.

“We are working with Dyndrite to provide the necessary tools and infrastructure to enable additive at scale. HP Universal Build Manager Powered by Dyndrite will deliver a new foundation for the industry through collaboration with other industry OEMs and ISVs.”

Output technologies supported include:

- HP Multi Jet Fusion

- Binder Jetting

- Selective Laser Melting (SLM)

- Powder Bed Fusion/DMLS

- Selective Heat Sintering (SHS)

- Electron Beam melting (EBM)

- Selective Laser Sintering (SLS)

- Fused deposition Modeling (FDM)

- Stereolithography (SLA)

- Digital Light Projection (DLP)

- Laminated Object manufacturing(LOM)

- Composite-Based Additive Manufacturing (CBAM)

HP Universal Build Manager Powered by Dyndrite is now in beta testing. To learn more or to sign up for the beta, click here.

Sources: Press materials received from the company and additional information gleaned from the company’s website.

About the Author

Press releases may be sent to them via [email protected]. Follow Robotics 24/7 on Facebook

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up