Dobot said its new CRA Series of cobots incorporate high performance harmonic drive reducers and electromagnetic brakes to offer customers greater performance and safety benefits. The company launched the new series at Automate this year alongside the CRV500 Smart Camera.

Founded in 2015 and headquartered in Shenzhen, China, Dobot offers 20 different cobots spread through six product series: CR, CRS, CRA, CRAS, MG400, M1 Pro, Nova, and Magician. It said it has sold 68,000 units in 140 countries and regions.

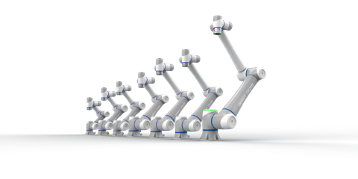

The CRA Series features seven different cobot models with payload capacities of 3 kg (6.6 lb.), 5 kg (11 lb.), 7 kg (15 lb.), 10 kg (22 lb.), 12 kg (26 lb.), 16 kg (35 lb.) and 20 kg (44 lb.) payloads and a working radius from 620 (24 in.) to 1,700 mm (66 in.).

The 3 kg, 5 kg and 10 kg payload models in the CRA Series are compatible with the DOBOT SafeSkin for safer human-machine collaboration. The SafeSkin is Dobot’s exclusive, self-developed non-contact pre-collision detection solution which can sense obstacles coming within 15 cm (5.9 in.) and stop before colliding.

Dobot keeps safety in mind

The CRA Series cobots were designed to be used in industries including consumer electronics, semiconductor, automotive, renewable energy, metal processing, logistics, healthcare, and retail.

The CRA Series supports Modbus, Ethernet/IP and Profinet communication, connecting with PLC and other automation system seamlessly. With 24 I/O ports available and PNP/NPN switching, expansion can be carried out more easily, according to Dobot.

The company noted the CRA Series cobots offer up to ±0.02 mm repeatability and 0.2 to 0.4 mm trajectory accuracy during complex motion. They feature electromagnetic brakes that auto-engage in 18 ms at power outage to restrict robotic arm falls less than 1 mm (.03 in.).

The CRA Series also has built-in virtual boundaries, real-time payload detection, and other safety features to ensure the safety of nearby workers.

The company highlighted the new operating system running on the CRA Series. It supports graphical programming, scripting and drag-to-teach for trajectory replay and can be used on desktop, mobile, and on a tablet.

New Dobot Camera takes advantage of 2.5D technology

At the exhibition, Dobot also launched another new product, the CRV500 smart camera.

With Dobot’s self-developed 2.5D spatial compensation technology, it can be used with the CRA and CR Series collaborative robots to enable accurate identification of objects’ horizontal angle and inclination for accurate grabbing.

The CRV500 Smart Camera can be set up using the DOBOT collaborative robot control software without further development for easy and quick deployment.

Editor's note: For more on Automate, check out Robotics 24/7's special coverage page.

Article topics

Email Sign Up