BEST (Boosting Engineering Science and Technology) Robotics is a national science, technology, engineering and mathematics (STEM) education nonprofit serving middle and high school students in 47 locations across 17 states. The organization sponsors a six-week student design competition that takes place during an after-school program.

Their competition has joined the cadre of competitions that seek to engage students, arousing their interest in STEM, and providing them with an opportunity to practice innovation in STEM design.

Rosemary Mendel is the organization’s executive director. We spoke to her to learn about the program and what it entails.

Digital Engineering: Can you provide an overview of the Best Robotics competition, how it came to be and the intent of the program?

Rosemary Mendel: BEST Robotics is the pathway that connects students to careers in STEM. Our hands-on program coupled with ongoing collaboration with higher education, industry and corporations, creates a direct pipeline for student success and workforce development. By incorporating coding, programming, math, engineering design and creativity, robotics gives students a tangible result of the STEM applications they are using. The competition is the culmination of the BEST Robotics after-school program.

Founded in Texas in 1993 by two Texas Instruments engineers, BEST Robotics has grown from a very grassroots, volunteer-driven efforts into a high-performing nonprofit contributing to efforts to have a positive impact on the future technology workforce.

Because the program is delivered at no cost to schools or students, BEST is able to uphold its values of accessibility, inclusion and diversity. As such, everyone is able to participate regardless of a school district’s location in a rural or inner-city area, or the economic circumstances of the community. Due to BEST’s relationship with its higher education partners, the BEST curriculum is reflective of the priorities that higher education has for incoming students. As a result, BEST students develop skills and proficiencies that will make them attractive candidates for recruitment into STEM majors.

DE: Who will be participating or who has participated?

Mendel: Our participants are middle and high school students representing 17 states from across the country. Our reach continues to grow as new hubs are added each year.

In 2018, 45% of our participant base lived in rural areas, 29% were from urban communities and 26% resided in the suburbs. Across our footprint, 80% of our teams were hosted by public schools. Interestingly, more than 50% of the schools participating have less than 800 students in total enrollment and approximately 30% have less than 400 students in total enrollment.

DE: How many participants have you had or are you expecting? Any demographics on participants?

Mendel: We annually engage approximately 20,000 students with the help of more than 30 universities and about 4,500 volunteers and mentors from industry and higher education.

Last year, 48% of our student participants identified as non-Caucasian and were from segments of populations identified nationally as being under-represented in our current STEM workforce. The largest segment among this group includes roughly 25% of students from Hispanic origin.

The gender ratio for our teams varies throughout our footprint and includes dozens of all-female teams. Overall, we’ve seen a continuous year-over-year increase in the number of female students participating. Last year, more than 35% of students were female.

DE: Can you tell us about some of the designs that are part of the event and how they came to be?

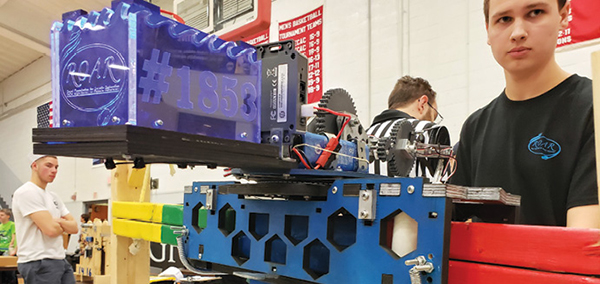

Mendel: BEST students are presented each year with an industry theme of the competition that sets out a problem for the robot to solve. Students have to create their own solution because of the constraints inherent in the simplicity of the materials that are used in our kits. Students have six weeks to build a robot from a kit of raw materials (plywood, PVC pipe, screws and nails) and a VEX processor.

Their designs are eclectic and incorporate many different uses. Mendelson described some of these unique innovations:

Golf ball caster wheels; telescoping arm made purely from duct tape; screw-drive scissor lift; gear casting using epoxy; a two-speed transmission (using a simple servo to change ratio); and a 3D printed belt drive pulley.

Some of the competition’s programming efforts included:

- Automated deployment sequences used at match start or to configure machine for specific tasks; often for alignment of machine with a part of the field.

- Gear shift speed selection, single-button reversible controls (akin to a swivel seat on heavy machinery), and single-button controller configurations—selectable to satisfy driver preferences or unique field configurations (e.g., left-hand vs. right-hand).

- The use of simulation to validate robot programming and modeling of robot and playing field in a 3D graphical simulation environment for design validation and driving practice. This allows the team to run time trials for various tasks and validate the design functionality and scoring strategy without needing the actual robot.

DE: Does BEST Robotics have a particular stance on adopting an innovation that is linked to the program? What drove them to sponsor the event and coordinate it?

Mendel: Our students create the innovations. They are challenged to do things that appear impossible considering the basic materials they are given. They must conceive and create new solutions in order to achieve success. Teams look to new technologies and methods to develop an understanding of how these technologies work and then figure out a way to replicate them using only the materials on hand.

For instance, rather than being provided with a set of matching gears, students must create their own lantern gears to satisfy the need for a 90-degree transfer of power from the motor. Similarly, students have fabricated their own two-speed transmissions, using a simple servo to change the gear ratios.

Adopting industry innovations is also a key part of the program. Given that our student participants are generally 2 to 10 years away from entering the workforce, keeping the subject matter, hardware and software relative to what’s happening in industry is critical.

DE: Anything else you’d like to tell us about the event that the above questions haven’t given you the opportunity to express?

Mendel: One of the key differentiators of the BEST Robotics program is in our approach to creating a level playing field for all of our students. Every team across the country receives an identical kit of raw materials from which they can build their robots. Kit components vary from year to year, but are mostly comprised of things like plywood, PVC pipe, duct tape, an occasional bobby pin and other basic supplies.

As a result, teams cannot gain a competitive advantage by purchasing additional parts. This dynamic forces teams to collaborate and incorporate input from multiple students in order to develop a winning strategy.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up