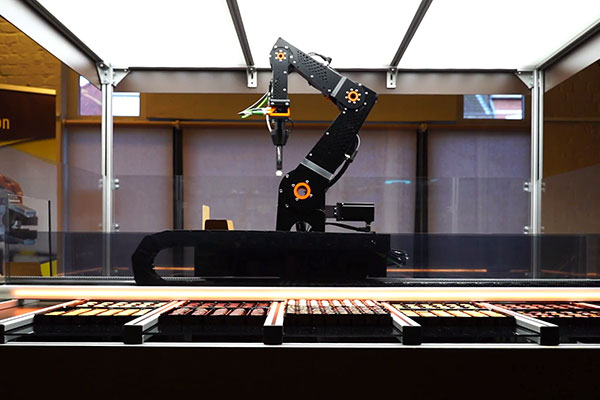

A customer enters Roose’s Chocolate World at Havenstraat 1 in Bruges. She approaches a box made of glass the size of a small room.

Inside, several displays filled with delicious chocolates in various colors and shapes. Is there a salesperson expecting an order? If so, they are nowhere to be seen. Instead, the customer places her finger on a touchscreen terminal, scrolls through the range, puts together a collection of chocolates, and places a transport box on the base of a robotic arm – alternatively, the selection even works with the smartphone.

After a simple click, the black and orange robot starts working. The electric assistant moves up and down the glass room, pivots its arm in all directions, reaches into the displays, picks up chocolates with a suction pad, places them neatly in the box, wraps the delicacies in gold foil, and returns to its starting position. The customer accepts the box, richer in treats and an unusual experience.

Michiel Roose, son of the owners of Roose’s Chocolate World, CEO of the Belgian mechanical engineering company Roose Automation and inventor of the Chocomatic:

“Customers are getting excited about our robot. In Bruges, the Chocomatic is slowly becoming a tourist attraction. Many people come especially with their children to watch the robot at work. There’s something almost magical about it.”

Chocomatic is not designed to set new productivity records or replace employees. Rather, the robot primarily entertains customers. Therefore, it was important to keep costs down and avoid expensive licenses that many robotics vendors with big brand names work with. Roose therefore went in search of a low-cost provider.

Roose recalls:

“The supply on the market is very manageable. I researched the Internet for a long time and found out: Virtually all roads currently lead to RBTX.”

RBTX is a marketplace for low-cost robotics, which unites manufacturers of robotic components in a construction kit. Robots from the Cologne-based plastics specialist igus® – including articulated arm robots, delta robots, and Cartesian vending machines – form the electromechanical framework. This framework can be expanded to include individual components from other manufacturers, such as cameras, GUIs, grippers, motors, sensors, or controllers. With just a few clicks, Roose assembled a robotic solution from these components.

Michael Hornung, product manager for drylin® linear and drive technology international at igus®:

“Compatibility is guaranteed because our engineers have assembled and tested all components in various combinations. Users thus enjoy investment security.”

Robot arm costs only 5,492 euros

To make Chocomatic a reality, Roose bought a robotic arm called robolink® from RBTX.

Hornung continues:

“At 5,492 euros, the arm costs hardly more than a powerful home computer and many times less than comparable industrial robot arms, which quickly run into tens of thousands of euros.”

The reason for the competitive price: igus® manufactures components such as the shaft gear not from metal but from triboplastics – from high-performance polymers that are optimized for maximum robustness and minimum wear. The control system for the robot – a development of the partner Commonplace Robotics – costs another 1,897 euros.

“So we got a complete turnkey solution for just under 7,500 euros,” Roose is pleased to say.

Operation is also cost-effective. “The tribopolymers from robolink® enable dry running without lubricants,” emphasizes the drylin® product expert. “Accordingly, costs for materials and maintenance are eliminated.”

And so it is not a problem that the robot moves more than absolutely necessary in everyday business. If it doesn’t have an order at the moment, it puts on a show, moves from right to left, and waves its arm – at least whenever sensors detect an audience in the room.

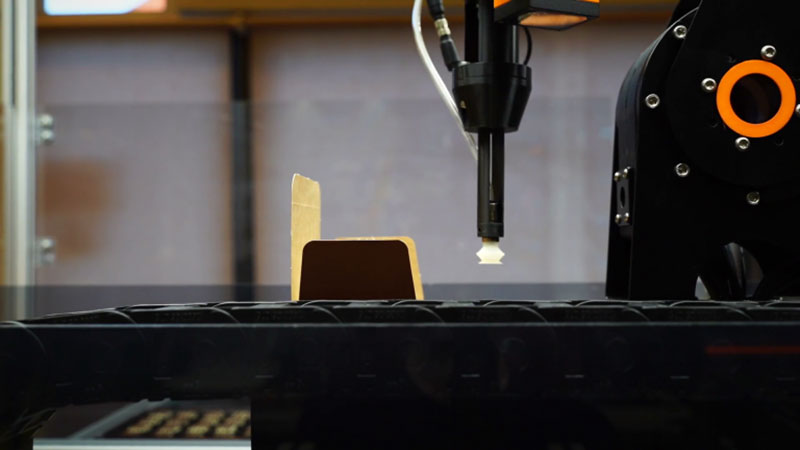

Without a scratch: robolink® grips chocolates with an accuracy of 0.8 millimeters

The robolink® is installed on a linear carriage, the so-called seventh axis. It is now moved up to 3m by toothed belt with the lubrication-free igus toothed belt axis ZLW-20160 – driven by the stepper motor NEMA23XL with a 5:1 gear. To enable a clean run without tangling, the energy and data cables are inserted in energy chains from igus, which follow the movement of the carriage.

The control system of the robot arm is integrated into its base. The electric worker finally learns how to pick thanks to software developed by Roose, which interacts with the control system via an interface. The in-house program evaluates the robot’s 3D camera images and calculates the position and sequence of the chocolates in the box.

Employees only need to switch on Chocomatic and refill confectionery occasionally – no extensive training is required. The robot moves autonomously to the individual specimens, picks them up with the vacuum gripper and places them in the tray – at a speed of 0.5 meters per second and with a repeat accuracy of 0.8 millimeters.

Roose adds:

“We are really excited about the precision of the robolink®. We can be sure that the robot will work reliably all day long and not damage the precious chocolates.”

Although Chocomatic has so far only been used at Roose’s Chocolate World, three more units have already been sold and are in production.

“More and more chocolate shops and museums are realizing that the solution is a real crowd-puller.”

Article topics

Email Sign Up