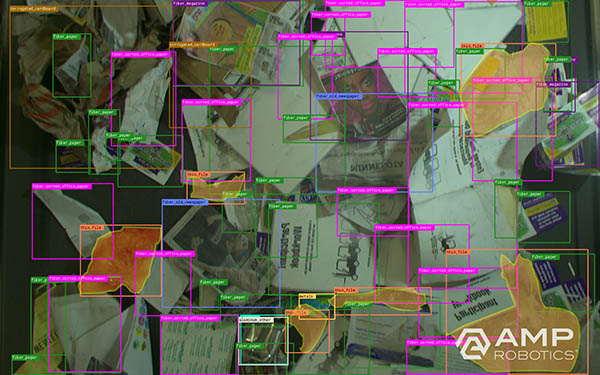

AMP Robotics Corp. is working to address the needs of materials recovery facilities, or MRFs, by using artificial intelligence, machine vision, and robotics. The Denver-based company today announced that it is developing an automated system that will help MRFs identify and separate film and flexible packaging.

The name of the new system is Vortex, and it was developed as part of the company’s Customer Innovation Program.

“Because these materials are complicated and expensive to reprocess into raw materials, end markets for film and flexible packaging have been limited,” the company said in a press release.

“While flexible packaging has been almost uniformly single-use, major brands continue to make commitments to use more recycled content in their products, and several states have recently adopted laws aimed at ramping up the use of post-consumer resin in plastic products and packaging. AMP is developing Vortex to target and recover film and flexible packaging for baling and selling,” it added.

Vortex will hit the mass market by 2023

AMP Robotics added the system has been “optimized for quality control on fiber lines.” It is working to deploy the system with its first customers now and plans to start selling it more broadly in 2023.

The company said Vortex helps address a major need in the recycling space.

“The recycling industry lacks infrastructure for the identification and separation of film and flexible packaging, and these materials jam MRF equipment not designed to handle it,” it added. “Even 2% to 3% film in overall MRF streams can be unmanageable to remove manually, often damaging equipment, necessitating downtime, and hindering recovery of recyclables.”

Related: How Plastics Recycling Can Improve With Robotics and Machine Learning

AMP part of the Film and Flexibles Recycling Coalition

The company is a member of The Recycling Partnership’s Film and Flexibles Recycling Coalition. The coalition was created to help address the challenges that come with recycling film and flexible packaging.

The coalition said its strategy consists of the following three parts, in its own words:

- Gather data on the impacts of available collection methods;

- Assess the most promising technological interventions and pilot new interventions; and

- Implement national interventions to drive the recycling of films and flexibles.

“The Film & Flexibles Coalition is seeking funding partners interested in tackling the substantive challenges associated with recovering post-consumer film and flexible packaging at a national scale,” said the organization. “We intend to have a broad set of stakeholders, including manufacturers, brands, retailers, resin suppliers, and recyclers, to advise the initiative and be part of the solution.”

More on AMP Robotics' other products

This is not AMP Robotics’ first foray into the recycling space. The AMP Cortex is the company’s robotic sorting and picking system designed to be used on “recyclables from mixed material streams.”

In addition, it has developed its own AI platform called AMP Neuron, which it uses to help its robots understand the different physical characteristics of the objects they are identifying and separating.

With AMP Clarity, customers have access to data that allows them to see more information about the materials they are recycling.

“Innovation and infrastructure improvements are vital to helping MRFs process this challenging, prolific material type and increase recycling rates for residential film and flexible packaging,” said Matanya Horowitz, founder and CEO of AMP Robotics, in a statement. “AI is laying the groundwork to reduce the contamination burden on MRFs and scale the recycling of film and flexible packaging.”

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up