The need to quickly, safely, and accurately sort recyclable materials from the waste stream is growing in urgency, as landfills fill up, international shipping of such materials decreases, and governments and citizens focus on sustainability initiatives. Just in time for Earth Day 2021, AMP Robotics Corp. yesterday announced that it has deployed six robotic sorting systems with recycler Evergreen.

Founded in 1998, Clyde, Ohio-based Evergreen supplies polyester resin and said it is one of the largest polyethylene terephthalate (PET or PETE) bottle recyclers in the U.S., processing more than 1 billion bottles, or 100 million pounds of post-consumer PET, per year.

Evergreen is a subsidiary of Greenbridge Packaging, formerly Polychem, a maker of polyester and polypropylene products. The Sterling Group portfolio company has served the food and beverage, consumer packaged goods, and manufacturing industries since 1974. Mentor, Ohio-based Greenbridge also supplies and supports tools, parts, and integrated equipment.

Evergreen applies AI, robotics to recycling

Louisville, Colo.-based AMP Robotics provides artificial intelligence, robotics, and infrastructure for the waste industry. AMP Cortex automates the high-speed identification and sorting of recyclables from mixed material streams.

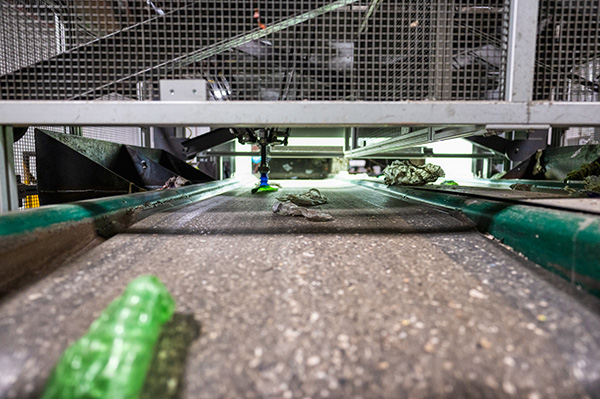

The AMP Neuron AI platform continuously trains itself by recognizing different colors, textures, shapes, sizes, patterns, and even brand labels to identify materials and their recyclability. Neuron then guides robots to pick and place the material to be recycled.

With deployments across North America, Asia, and Europe, AMP said its technology recovers recyclables from municipal waste, precious commodities from electronic waste, and high-value materials from construction and demolition debris. The company has a presence in more than 25 U.S. states.

Evergreen's facility in Ohio uses the six AMP systems to identify and sort green and clear PET from post-consumer bales of plastic soft-drink bottles, which it recycles into reusable flakes or pellets (rPET) and sells to end markets as feedstock for new containers and packaging. The company is investing $24 million to double its capacity.

“As a leader in the recycling of post-consumer PET bottles, the precision and accuracy of AI and robotics has aided our ability to better monitor the composition of material throughout our operation, boost recovery, and ensure high quality in the rPET resin we produce,” stated Greg Johnson, vice president of operations for Greenbridge and Evergreen. “AMP’s technology aligns with our core values of environmental responsibility, sustainability, the safety and well-being of our team, and profitability.”

AMP and Evergreen noted that products made from rPET can be recycled again. This is important as states consider legislation that would charge producers higher rates for hard-to-recycle packaging and encourage packaging design that uses more recycled content, the partners said.

If plastics are not properly separated during the sorting phase and different materials get processed together, it produces a lower-quality resin, which may not meet manufacturers’ product standards and the stringent requirements for food-grade and beverage containers.

AMP said its installation at Evergreen demonstrates the company’s continuous market expansion with plastics reclaimers in addition to its infrastructure modernization efforts with materials recovery facilities.

“Greenbridge and Evergreen are leading the way in applying innovation to increase the capture and processing of post-consumer resin,” said Matanya Horowitz, founder and CEO of AMP Robotics. “With the U.S. recycling less than 10% of plastics produced annually, their application of advanced technology is expanding recovery, diverting material from landfill, and lowering greenhouse gas emissions.”

“AI-guided sortation can deliver scientifically calibrated mixes of material to meet reclaimers’ specifications and those of end-market buyers,” he added. “The technology helps ensure a higher-quality end product and a larger volume of recycled material for brands to source for their recycled content goals and sustainability commitments and improves the bottom line of reclaimers who supply it.”

AMP Robotics continues to scale up

In addition to PET, AMP said its AI platform can identify and capture plastics including high-density polyethylene (HDPE), low-density polyethylene (LDPE), polypropylene (PP), and polystyrene (PS). The company's systems can sort further by color, clarity, and opacity, as well as different form factors, such as lids, tubs, clamshells, and cups.

AMP’s technology, which uses NVIDIA processors, can also recover cardboard, paper, cans, cartons, and other container and packaging types reclaimed for raw material processing. It can quickly adapt to container packaging by brand, helping meet the demand for sufficient quantities of high-quality recycled material as consumer packaged goods (CPG) companies commit to using post-consumer content.

Last month, AMP announced the launch of its automated secondary sorting facilities, which apply AI to sort low volumes of residue to recover mixed plastics. These material streams also contain high-value recyclables such as used beverage cans (UBCs) and old corrugated cardboard (OCC) that are in high demand for resale to aluminum manufacturers and paper mills.

AMP Robotics said its secondary facilities can drive down the cost of recovery while creating contamination-free, high-quality bales of recycled material for resale. The company added that its business model introduces market certainty and new revenue streams for established materials recovery facilities (MRFs) by creating demand for residue that businesses would otherwise pay to dispose of.

In January, AMP said it had raised $55 million in corporate equity in a Series B financing, led by XN with participation from new investors Valor Equity Partners and GV as well as existing investors. AMP is using this latest funding to scale its business operations, develop new AI applications, and expand its work with CPG companies such as Keurig Dr Pepper.

Article topics

Email Sign Up