Amazon Robotic Fulfillment Center, North Haven, Connecticut

- Opened: June 2019 (watch video)

- Size: 855,000 square feet

- Dock Doors: 62

- SKUs: 1 million +

- Throughput: 1 million + orders per day during peak

- Shifts: 2 10-hour shifts per day, with downtime for maintenance between shifts

- Employees: 2,500 full-time associates, each working 4 shifts per week

- Primary Material Handling Equipment: Goods-to-person picking on a four-level pick module enabled by Amazon Robotics; ten miles of conveyor and sortation; cubing and weighing, automatic labeling, spiral conveyors and trailer-loading conveyor

- Area of Coverage: The facility’s primary role is the fulfillment of Prime orders in southern Connecticut

Amazon Robotic Fulfillment “What Did You See?”

That’s the question a colleague asked after I toured Amazon’s 855,000 square foot robotic fulfillment center in North Haven, Connecticut last week. It’s one of 50 robotic fulfillment centers worldwide, and one of five facilities currently operating in Connecticut, including another fulfillment center about 50 miles away in Windsor; a parcel sortation center in Wallingford, a last-mile Amazon Logistics delivery station in Bristol and an Amazon Air Hub in Hartford.

Let me cut to the chase and answer that question before I fill in the details: The materials handling systems are impressive. There are ten miles of conveyor and sortation, several thousand autonomous mobile robots from Amazon Robotics, and by my estimate, an automated labeling system after packaging. That’s what you see.

What’s More Impressive Is What You Don’t See!

That’s the scale of Amazon’s ecosystem and the intelligence behind the solution, the software and algorithms developed from the experience of shipping billions of packages over the past 26 years.

Those algorithms and software determine how to allocate millions of SKUs and more than 100 million individual items across 185 fulfillment centers to meet promised delivery dates. Combine that with Amazon’s extensive network, and you have a customer-focused supply chain that can’t be easily replicated.

As spokesperson Todd Walker (PR Manager at Amazon) repeated several times during my visit, and in a follow-up email;

“The number one factor [in everything we do] will be customer preference…The customer experience comes first.”

While anyone with a budget can install goods-to-person picking technologies and ten miles of Dematic conveyor and sortation, automation alone can’t deliver a customer experience. That, in my opinion, is Amazon’s secret sauce.

Visit Amazon's Blog: Inventing for Customers is in our DNA

The Amazon Automation Flow Looks Something Like This

Merchandise enters the supply chain through cross-dock facilities. In those, shipping containers and pallets are broken down into smaller units that are then allocated to the fulfillment centers according to local demand.

The North Haven facility probably stocks a good selection of Yale-related merchandise since the university is just down the road; for a facility in California – not so much. Sortable items that are small enough to be handled on a conveyor and sortation system go to facilities like North Haven, while non-sortables go to facilities designed to handle larger items.

At the North Haven facility, newly received merchandise is decanted into totes, including products that can be shipped in its transport packaging. Those totes are then routed to one of four pick module levels. On each level, robots and storage cubes are behind a caged area; pick stations and “stow” stations, Amazon’s term for replenishment, line the length of storage area. Walker pointed out one interesting innovation in the pick modules. As in the old Kiva facilities, only a limited number of associates are allowed in the caged area with the robots, and then to address problems, like an item falling to the floor from a storage cube. Those associates wear a special vest that communicates their location to the robots to avoid collisions.

During the stowing process, you see another innovation Amazon Robotics’ has brought to the Kiva party. The old transportable industrial shelving used in a Kiva system has been replaced by a four-sided storage cube with soft, flexible shelving. Two sides have spaces for larger and deeper items while the other two sides are dedicated to smaller items. The product is held in place by simple bands that look little like exercise bands.

Putaway is random to maximize the cube, and based on the stow associate’s experience. But lights do highlight shelves where the system’s business rules have determined that product shouldn’t be stowed.

The associate scans the item into place and then confirms the putaway with the press of a button. Items that appear damaged or don’t scan properly are placed in a hospital tote that will be addressed by a special team. Going back to that customer experience, this is one of the first quality checks.

Read: Despite Robophobia, Robotics Have Positively Impacted Warehouses

Picking takes place side by side with replenishment. In that process, the order selector gets instructions on a screen and a light highlights the shelves where the product is to be picked from. Once totes are complete, they’re pushed onto a takeaway conveyor. When the storage cube has been picked complete, the robot moves in front of an array of cameras next to the workstation.

The system analyzes a captured image to verify that the right items are still on the cube and that the wrong items weren’t picked before it goes back into storage. That’s the next quality check.

In another area of the facility, items that are expected to be ordered in large quantities for promotions are stored at the pallet level on pallet-handling robots that are delivered to a workstation for picking.

From picking, totes are conveyed to a multi-line or single-line packing station. There the system tells the packer what size box to use if an item can’t ship in its original packaging. The packer seals the carton, applies any required labels and pushes it onto an outbound conveyor. Packages then go to a cubing and weighing station that verifies that the weight and size of the package are within expected limits; if so, a shipping label is automatically applied.

Amazon calls this process SLAM, an acronym for Scan Label Apply Manifest. If not, it’s kicked off the conveyor to an inspection station, where the package is opened and the contents are verified. Once a package has been validated, it's sorted and conveyed into a trailer.

That’s Not the End of the Amazon Story

This is where that ecosystem comes back into play. Orders ready for delivery go to a sorting center to be routed by zip code. They’re either picked up at the sorting center by a third party parcel service like USPS or transported to an Amazon Logistics delivery station for last-mile delivery.

David Bozeman, vice president of Amazon Transportation Services, calls the sort centers the heart of Amazon’s supply chain because they pump packages out to the appropriate places.

There are two exceptions to that process: UPS bypasses the sorting center and picks up directly from the fulfillment center. The other is orders that include inventory not stocked in North Haven.

At that point, “the number of factors will determine how an order like this gets fulfilled,” says Walker, adding that “the number one factor will be customer preference.” If a customer has chosen to receive items as they’re ready to ship, then Amazon may send multiple boxes to meet the promised delivery time.

If a customer has chosen to receive items in one box, then the items will be merged at another fulfillment center, like the facility in nearby Windsor, and then go through the sort and ship process.

Sustainability is also factored into the delivery equation, with algorithms determining the most sustainable way to fulfill the order and still deliver on the customer promise.

When you get to tour a highly-automated facility run by a company like Amazon, it’s easy to get a little star-struck, like meeting a celebrity.

When I drove back to New Hampshire, however, the thing that stuck with me wasn’t the materials handling automation – I’ve seen lots of pretty cool automation - but the innovations and steps Amazon have put in the process to validate the integrity of the order and deliver on the customer experience. The intelligence and learnings it takes to do that – the things you don’t see - really are the company’s secret sauce.

Related Article: Can Robots Help Build A Better Supply Chain Future?

Planning For the Warehouse of the Future

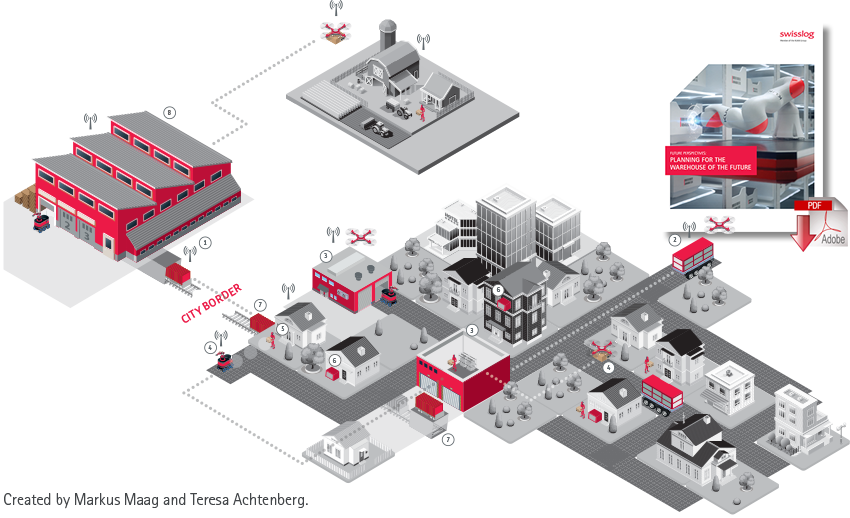

Conceptual view of distribution in the future, showing a large warehouse outside a city supporting multiple urban distribution centers with a variety of transportation options from the central warehouse to the urban DC and from the urban DCs to consumers.

Download the Paper: Planning for the Warehouse of the Future

Related White Papers

The Supply Chain of the Future: Integrated and Automated

TThe changes occurring in the warehouse today will need to extend upstream to production processes and downstream through last-mile delivery. Download Now!

Flexible Robotics: A Pillar of The Future-Ready Warehouse

With the continued march of e-commerce and omnichannel fulfillment, warehouse operators must get efficient at order picking at the “each” level, simply throwing more human labor at the challenge becomes expensive and hard to sustain. Download Now!

Insights From The world’s Leading AutoStore Integrator

There are a number of integrators that can offer AutoStore hardware today, but not all AutoStore deployments are created equal. Download Now!

More Related Resources from Swisslog

About the Author

Follow Robotics 24/7 on Linkedin

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up