While the fight against the COVID-19 pandemic continues, robots are still helping with research and diagnostics. ABB Robotics yesterday said it has developed an automated neutralizing antibody testing system with the University of Texas Medical Branch, or UTMB. The company said it is “the most effective means of determining an individual’s immunity to various strains of COVID.”

“The ability to carry out more daily tests is the key to generating more data on individual immunity profiles that will help control the further spread of the virus,” stated Dr. Michael Laposata, professor and chairman of the Department of Pathology at UTMB.

“By transforming the rate at which testing can be carried out and eliminating the need for large numbers of laboratory staff being exposed to the potential risk of infection in manual testing, the automated system we’ve developed with ABB provides an accurate, fast, flexible and safe way of meeting our goals,” he added.

ABB Robotics & Discrete Automation said it offers industrial automation, autonomous mobile robots (AMRs), and other systems for industries ranging from automotive and electronics to logistics and healthcare. The unit of Zurich-based ABB employs about 11,000 people at more than 100 locations in approximately 53 countries.

ABB helps UTMB keep up with virus mutations

The continued mutation of the COVID virus since late 2019 has presented a major challenge for both medical researchers and governments, as both seek ways to limit its spread, noted ABB. Although numerous vaccinations have been developed, the rapid mutation of the virus makes finding the most effective protection against each variant more challenging, it said.

“The aim of the automated neutralizing antibody test is to specifically detect a SARS-CoV-2 neutralizing antibody without cross-reaction with other infection, making this assay a gold standard for COVID-19 serological testing,” said ABB.

“The resulting data will then be used both by the person being tested and by researchers to better understand immunity from vaccination or infection,” the company said. “The data will also inform local policymakers’ decisions on how to minimize the risk of further infection, such as avoiding virus hotspots.”

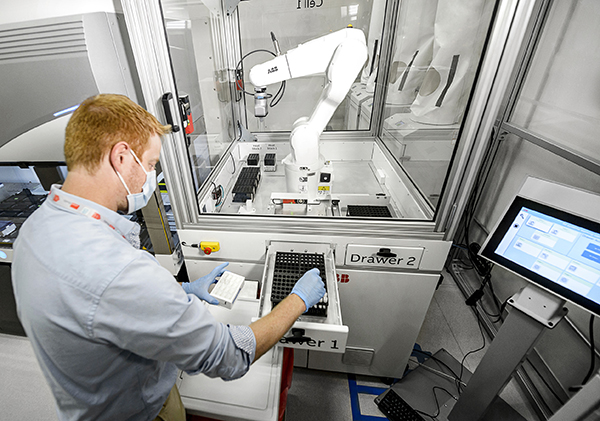

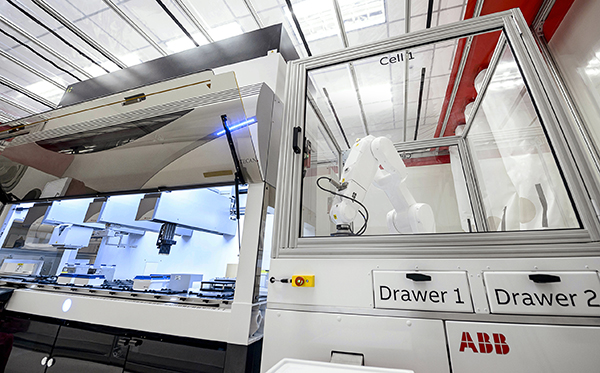

UTMB researchers developed the automated neutralizing antibody test using ABB's RobotStudio offline programming software to model, iterate, and test different combinations of lab equipment and robot positions. Their goal was to create an effective working concept.

As a result of this process, a working system was produced from inception into operation within just 18 months, greatly cutting the amount of time typically required for a project of this type, said ABB.

“What we managed to achieve in this project within such a short space of time is extraordinary,” said Juan Garcia, director of laboratory services at UTMB. “Many multimillion-dollar companies take several years to create solutions like the one we’ve developed in a fraction of the time.”

RoboStudio leads to increased testing

The Life Sciences and Healthcare Lab, located at the Texas Medical Center Campus in Houston, has used the system developed by ABB Robotics to increase the number of neutralizing antibody tests performed from 15 to over 1,000 daily.

Not only will automating testing enable UTMB to assess more people for immunity against the different strains of COVID, but it will also help them gain a greater understanding of vaccine effectiveness, said the researchers.

“None of what we’ve achieved could have been done without ABB or any of the other parties involved in this project,” said Dr. Labosata. “From the creation and simulation of a working concept in RobotStudio software through to delivering the physical automated testing cells that are now in use in our laboratory, this is the greatest experience of teamwork I have witnessed in 35 years in this business.”

“This project is a clear example of how robotics can increase speed and efficiency while making work safer for the researchers involved,” said Daniel Navarro, managing director of consumer segments and service robotics at ABB. “Working closely with UTMB, we are combining our expertise on biology, lab process, automation, and software to develop and deploy an automated robotic solution that significantly advances and informs our response to the COVID pandemic.”

In addition, the automated system could be used for other types of virus testing, said ABB. The company said the healthcare project is one of several worldwide using its robots to help find ways to protect people against COVID-19.

Article topics

Email Sign Up