While the debate continues over whether automation is displacing human workers, the latest reports suggest otherwise. Fifty-seven percent of global manufacturers said they believe that robots are not replacing human workers in their facilities, but are rather working alongside humans to supplement their work, according to a study released yesterday by Veo Robotics Inc.

“Our findings highlight that the majority of manufacturers are increasing automation with the goal of robots working alongside human co-workers rather than directly replacing them,” said Patrick Sobalvarro, co-founder and CEO of Veo Robotics. “We find that using robots increases the productivity and the value of human workers, freeing them to use their intelligence, judgment, and dexterity in their work.”

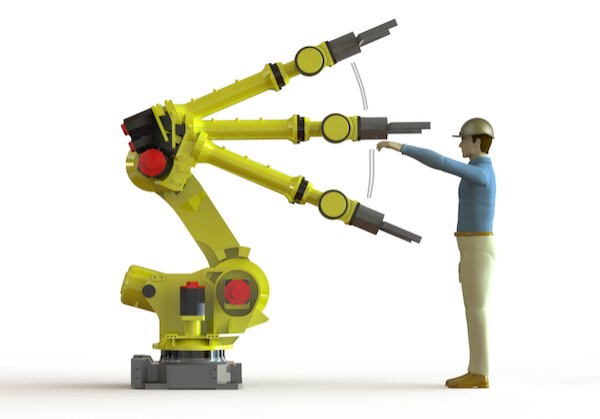

Waltham, Mass.-based Veo Robotics has build sensing and intelligence for industrial robots to safely collaborate with people. The company has created the FreeMove 3D safeguarding system, which it said enables fluid, efficient, and flexible production lines. Veo currently partners with the world’s top four robot manufacturers: FANUC, Yaskawa, ABB, and KUKA.

Veo finds manufacturing automation on the rise

Veo Robotics’ “2022 Manufacturing Automation Outlook” also found that 61% of manufacturers said that human-robot interaction within their facilities has increased over the past year. The report noted that people are increasingly working alongside robots as manufacturers grapple with inflation, ongoing supply chain challenges, and unprecedented labor shortages.

Since the COVID-19 pandemic, nearly all manufacturers are looking to automate more operations, including turning to robots to handle mundane, repetitive, or overly risky tasks, said Veo. North American robot purchases reached a record high in 2021, according to the Association for Advancing Automation (A3), and global sales could increase to $31 billion by 2028, said Fortune Business Insights.

Veo Robotics surveyed more than 500 manufacturers across the U.S., the U.K., and Japan to explore how these organizations are integrating robots into their workforce, as well as the resulting effects on facilities and their human workers.

As speculation about the effect of robots on local job markets continues to contribute to mixed public opinion, Veo said its data suggests most manufacturing professionals do not believe that their jobs are at risk due to the increased adoption of robots.

Human-robot collaboration requires safety, speed

The rise in interactions between human and machine co-workers also necessitates new safeguarding methods that don’t hinder productivity, asserted Veo Robotics. Although 63% of manufacturers told the company that they were at least “moderately satisfied” with their safety when interacting with robots, 41% said they keep their robots in fully fenced, caged environments to prevent injury or harm to human workers.

This reliance on fully caged robots often hinders modern manufacturing facilities' speed, efficiency, and flexibility, claimed Veo.

In fact, 44% of manufacturers noted that their workers need to enter workcells at least every one to two hours. In addition, 63% reported that their current workcell safeguarding systems pose challenges in the form of limiting flexibility, increasing human workloads, constraining space, and slowing down production time.

Additional highlights from Veo Robotics’ “2022 Manufacturing Automation Outlook” included:

- Over 55% of manufacturers reported having 10 or more robots in their facilities, with nearly one in three (32%) saying they have 30 or more

- Eighty-one percent of manufacturers said they deal with robot-led production shutdowns

- More than a fifth of respondents said that nuisance faults with their current robot workcell safeguarding methods cause production to shut down at least every couple of hours

- As inflation hits manufacturers, 33% of respondents noted that “reducing the cost and complexity of manufacturing” was one of their biggest challenges over the next six months to a year

- Other manufacturers noted that supply chain constraints (34%) and hiring and training of skilled workers (37%) were still their biggest problems

“Innovation being embraced within industrial processes is a great sign,” said Sobalvarro. “But as the machine workforce evolves, so must the work environment.”

“Modern manufacturing facilities and warehouses do not have the time to halt production in every situation where a human worker needs to enter a cage,” he added. “A much more efficient and flexible safeguarding method is speed and separation monitoring—SSM—which enables workers to interact safely with robots without entering the caged work environment. With SSM, manufacturers can prioritize safety and productivity without sacrificing one for the other.”

Article topics

Email Sign Up