Editors’ Picks

Found in Robotics News & Content, with a score of 70.23

VELO3D has formed a U.S.-wide partnership with GoEngineer. GoEngineer will operate as an extension of VELO3D, dedicating resources to educate designers about the potential of SupportFree technology for their designs, as well as sales and service expertise supporting the complete solutions portfolio including Flow pre-print software, Sapphire metal AM printer, and Assure quality assurance and control system. GoEngineer reportedly will be VELO3D’s largest partner in the United States; existing sales networks and direct purchase opportunities from VELO3D remain in place. With more than 35 years of experience and thousands of customers in high tech, medical, machine design, energy, and other…

Found in Robotics News & Content, with a score of 65.62

VELO3D and Honeywell Aerospace, a user of additive manufacturing (AM) technologies with knowledge across various platforms and applications, have announced a partnership to qualify VELO3D’s Sapphire system as a manufacturing platform for 3D print production of aircraft components. The Sapphire system was selected for its capabilities for building complex geometries without the requirement of support structures. The VELO3D Sapphire system will be in Honeywell Aerospace’s Phoenix facility. The qualification process is underway and is focused on INCONEL, a nickel-based super alloy well suited for extreme temperatures. VELO3D will provide their expertise in developing suitable parameter sets for Honeywell Aerospace to…

Found in Robotics News & Content, with a score of 65.44

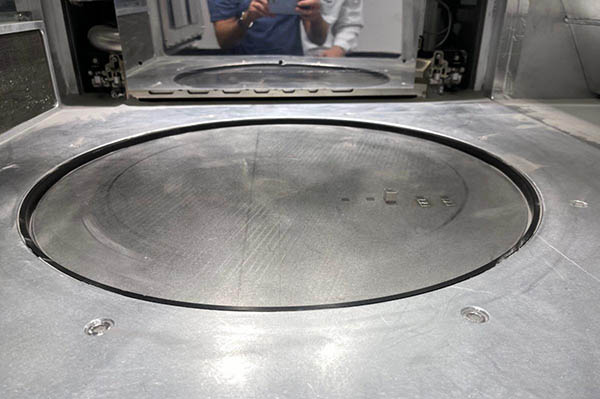

…expanding its additive metals offering with the addition of VELO3D’s Sapphire 3D print system and Flow software. The Sapphire laser fusion metal additive manufacturing system allows for printing of complex part geometries with in-situ metrology, closed-loop control, and low-to-no support structures. The solution’s built-in tools include support generation, simulated print predictions, per-surface process application, slice composer and process review. This functionality allows for 3D printed production of complex metal components with more quality control, the company reports. “The Sapphire system from VELO3D is an important part of advancing our capabilities to include using additive metals in applications and geometries previously…

Found in Robotics News & Content, with a score of 63.39

VELO3D announces that it has partnered with Boom Supersonic, the Colorado company building a fast supersonic airliner, to manufacture the flight hardware necessary to build XB-1, Boom’s Mach-2.2 supersonic demonstrator aircraft. Boom is leveraging VELO3D’s Intelligent Fusion technology. XB-1 is an independently-developed supersonic jet that is aiming to prove the key technologies in-flight for safe, efficient travel at Mach 2.2 (1,687mph). XB-1 combines over 3,700 parts and some of the most advanced technologies including advanced carbon fiber composites, a refined delta wing planform, and an efficient variable-geometry propulsion system. XB-1 has functional, performance, and precision requirements, so Boom turned to…

Found in Robotics News & Content, with a score of 57.07

VELO3D Inc. today announced that it is merging with JAWS Spitfire Acquisition Corp. The additive manufacturing company said it expects to be listed on the New York Stock Exchange under the ticker symbol “VLD” once the transaction is completed, which is expected to happen in the second half of 2021. Campbell, Calif.-based VELO3D said its proprietary technology for 3D printing of metals integrates software, hardware, and process-control innovations. Manufacturers can use VELO3D's Flow print-preparation software, Sapphire laser powder-bed additive manufacturing (AM) system, and Assure quality-assurance software to reduce costs, improve quality control in serial production, and be more responsive to…

Found in Robotics News & Content, with a score of 53.17

VELO3D this month announced that Primus Aerospace has joined its partner network with the purchase of a Ti6Al4V Sapphire metal additive manufacturing system. Primus Aerospace is a a leading contract manufacturing partner to aerospace and defense OEMs and Tier 1 suppliers worldwide. Established in 1989, the Lakewood, Colo.-based company has grown into a vertically-integrated manufacturing operation. It also operates a sales and engineering office in Arizona and a distribution warehouse in the Netherlands. Primus' customers include Lockheed, Boeing, Northrop Grumman, General Dynamics, and Raytheon. VELO3D said its integrated, full stack offering of software, hardware, and process-control innovation allows engineers to…

Found in Robotics News & Content, with a score of 51.76

Last week, Velo3D Inc. announced the delivery of its first Sapphire XC metal 3D printer to an aerospace customer. The additive manufacturing system is designed for faster production and larger, mission-critical parts, according to Velo3D. “I believe that the Sapphire XC will quickly become the gold standard in advanced metal additive manufacturing,” stated Benny Buller, founder and CEO of Velo3D. “Because our customer is already utilizing our end-to-end production solution, they can immediately and seamlessly move parts to Sapphire XC to achieve a phenomenal production rate increase.” “We made a huge effort to ensure that Sapphire XC uses the exact…

Found in Robotics News & Content, with a score of 50.45

VELO3D today announced that Chromalloy, which supports gas turbine engine manufacturers and operators worldwide, recently selected its VELO3D Sapphire system. Chromalloy will use additive manufacturing for maintenance, repair, and operations (MRO) projects in the aviation and energy markets. Palm Beach Gardens, Fla.-based Chromalloy develops systems to reduce operating expenses and extend the life of gas turbine engines. The company, a subsidiary of Sequa Corp., is authorized by the U.S. Federal Aviation Administration, the European Union Aviation Safety Agency, and other national aviation authorities. It is also qualified under ISO (International Organization for Standardization) and National Aerospace and Defense Contractors Accreditation…

Found in Robotics News & Content, with a score of 50.42

Velo3D Inc. today said that it and Launcher Inc., which develops high-performance rockets for small satellites, are proving the value of 3D printing for cost-effectively and flexibly delivery these satellites to orbit. In April, Launcher purchased a metal additive manufacturing system to print Inconel parts, and it recently added another one that prints titanium. “Rocket engine turbopump parts typically require casting, forging, and welding,” said Max Haot, founder and CEO of Launcher. “Tooling required for these processes increases the cost of development and reduces flexibility between design iterations. The ability to 3D print our turbopump—including rotating Inconel-shrouded impellers, thanks to…

Found in Robotics News & Content, with a score of 48.48

VELO3D Inc., which specializes in additive manufacturing for metal parts, today said that Vertex Manufacturing, a provider of CNC machining and manufacturing services from development through production, has chosen it to help meet growing demand for 3D-printed “impossible” metal parts. “At VELO3D, we help innovators like Vertex accelerate the future of manufacturing, not just for their customers, but to benefit all of humanity,” stated Benny Buller, founder and CEO of VELO3D. “This new partnership speaks to the real and transformational capabilities VELO3D is bringing to metal additive manufacturing.” Founded in 2014, VELO3D offers fully integrated, patented systems including the Flow…

Found in Robotics News & Content, with a score of 39.24

…The four companies are Desktop Metal, ExOne, Rapidia and Velo3D. Key trends, such as manufacturers seeking manufacturing flexibility, supply chain efficiency, lightweighting and part consolidation are making the 3D metal printer market one of the fastest-growing segments of the 3D printing business. From the supply side, new 3D metal printing technologies are reducing costs while providing greater quality and production speeds than have been available in the past. “The 3D metal printing market is seeing dynamic growth, and a key part of that growth is the development of new technologies and materials. These new products are creating new capabilities that…

Found in Robotics News & Content, with a score of 17.74

…in the hundreds of thousands of dollars, he adds. Velo3D has carved out a specialty area in metals, not composites, though it, too, places an emphasis on addressing challenges related to supports. The firm, which caters to the oil and gas sector, among other industries, offers SupportFree technology that enables printing at low angles and overhangs down to zero degrees as well as large diameters and inner tubes up to 100 mm without reliance on supports. The Sapphire laser powder bed fusion metal AM system, designed for SupportFree production output, is being readied in a version that supports a 315-mm…