Editors’ Picks

Found in Robotics News & Content, with a score of 30.27

…it has made a formal, non-binding offer to acquire Stratasys Ltd. for $18 per share in cash. The company previously said it views Stratasys as a “strategic, complementary asset in the relatively mature polymer-based AM [additive manufacturing] market segment.” “We have great respect for Stratasys’ business, including Chief Executive Officer Dr. Yoav Zeif, who we believe is the architect of Stratasys’ recent positive momentum,” stated Yoav Stern, chairman and CEO of Nano Dimension. “Together, Nano Dimension and Stratasys can offer an increasingly exciting set of solutions for customers while becoming better positioned to compete in the AME [additively manufactured electronics]…

Found in Robotics News & Content, with a score of 7.29

…expand its team in Los Angeles. Its employees have worked at organizations including SpaceX, Microsoft, Google, Northrop Grumman, and Stratasys. For a current list of job openings at Machina Labs, visit www.machinalabs.ai/careers.

Found in Robotics News & Content, with a score of 10.99

…to take advantage of Velo3D’s contract manufacturing partners like Stratasys Direct Manufacturing when scaling up production. Launcher successfully tested the liquid oxygen (LOX) turbopump for its high-performance, closed-cycle liquid rocket engine at NASA’s Stennis Space Center. The company is now working with Velo3D to 3D-print its fuel pump, flight turbine housing parts, and Orbiter pressure vessels. It will make these vessels with the second Velo3D Sapphire metal AM system. “Velo3D really delivered on our turbopump, including its 3D-printed rotating impeller, all of which functioned perfectly the very first time at 30,000 rpm, using the first prototype,” said Haot. The sky's…

Found in Robotics News & Content, with a score of 11.32

MakerBot, a Stratasys company, reports that the BASF Ultrafuse 316L Stainless Steel material by Forward AM has been qualified for the MakerBot LABS Experimental Extruder for the MakerBot METHOD 3D printers. With an open materials platform and a portfolio of advanced engineering-grade materials, METHOD is an industrial desktop 3D printer with a heated chamber that can print polymer, composite and metal materials. Ultrafuse 316L Stainless Steel material combines strength, rigidity and durability needed for applications including functional prototypes and manufacturing tools. Available using the MakerBot LABS GEN 2 Experimental Extruder, this metal-polymer composite material provides METHOD users with an option…

Found in Robotics News & Content, with a score of 50.23

Stratasys Ltd. introduced an acrylonitrile butadiene styrene-based carbon fiber material for its line of F123 Series 3D printers, the first composite material for the platform. Carbon fiber materials have proven popular on Stratasys’ industrial-scale FDM (fused deposition modeling) 3D printers for various end-use applications such as jigs, fixtures and tooling, company says. With FDM ABS-CF10, Stratasys now makes carbon fiber more accessible to the engineering and manufacturing community with high-performance F170, F270 and F370 3D printers. The material properties of FDM ABS-CF10, featuring 10% chopped carbon fiber, an alternative to metal parts. The material is said to be stronger and…

Found in Robotics News & Content, with a score of 35.50

…dust extractor prototype illustrates J850 Pro 3D printer from Stratasys. Image courtesy of Stratasys. Stratasys Ltd. has unveiled a new solution in the company’s family of multi-material enterprise PolyJet 3D printers. The new J850 Pro 3D printer offers J8 series capabilities tailored specifically to engineering needs, without full color. It enables engineers to produce prototypes for concept verification, design validation and functional performance using the latest materials, including transparent VeroUltra Clear. The J850 Pro complements the existing J850 Prime for designers and engineers who also need full-color printing. With its capacity for seven materials jetted simultaneously, fast printing and high…

Found in Robotics News & Content, with a score of 5.64

…Related Stories AM’s Role in Future-Proofing the Supply Chain Stratasys Organizes 3D-Printed Protective Gear Drive to Fight COVID-19 Frontline 3D Printing During the shutdown, Greg Paulsen, director of Application Engineering for on-demand manufacturing service provider, Xometry, says he saw among his customers, “the willingness to explore 3D printing as a way to make end-use products.” He adds, “Some customers found that the lead time to move to molding or casting just didn’t fit their deadline. We made a lot of them believers in AM.” The pandemic is not over yet, but manufacturers are finding ways to reopen and resume production…

Found in Robotics News & Content, with a score of 43.25

Stratasys has launched a new program to integrate its 3D printers in production environments with the factory floor via the GrabCAD Software Development Kit (SDK). Each SDK package includes a complete set of application programming interfaces documentation, and code samples that enable development partners and manufacturing customers to establish two-way connectivity between Stratasys FDM 3D printers and enterprise software applications. Stratasys has previously introduced support for MTConnect, an industry-standard protocol that enables customers to communicate factory data. However, this standard does not support additional capabilities for sending and receiving printer commands and for remote monitoring. Stratasys is now meeting the…

Found in Robotics News & Content, with a score of 38.98

Stratasys Ltd. has signed an agreement to acquire 3D printing start-up Origin Inc. in a transaction for total consideration of up to $100 million, including cash and stock. The merger enables Stratasys to expand through innovation in the mass production parts segment with a next-generation photopolymer platform. Subject to various approvals and other closing conditions, the acquisition is expected to close in January 2021. Stratasys expects Origin’s Programmable PhotoPolymerization (P3) technology to be an important growth engine for the company, adding up to $200 million incremental annual revenue within 5 years, the company says. The acquisition will help fortify Stratasys’…

Found in Robotics News & Content, with a score of 49.66

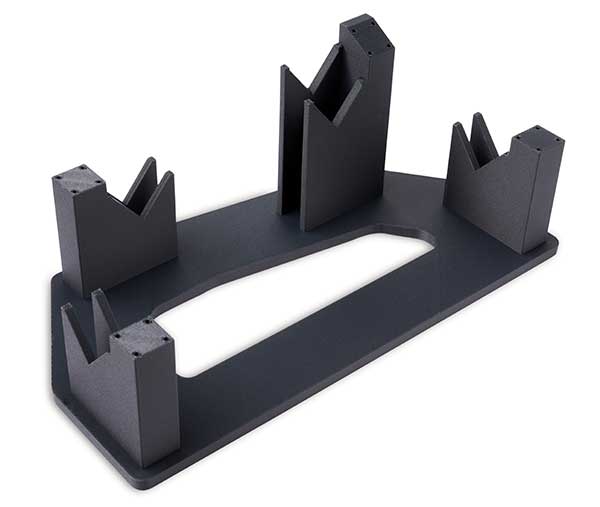

Stratasys is making additive manufacturing even easier thanks to a new collaboration with nTopology, innovator of next-generation design and engineering software. The two companies are providing a series of accessible, customizable design for additive manufacturing workflows for their users, starting with the FDM Assembly Fixture Generator. Stratasys FDM printers have become powerful, supporting advanced materials like Nylon 12 Carbon Fiber and reaching accuracy and reliability required for use on commercial airplanes and even the International Space Station. But designing with existing engineering software tools still creates long lead times, slowing additive manufacturing's march to pervasive adoption. The new Stratasys |…

Found in Robotics News & Content, with a score of 11.47

MakerBot, a subsidiary of Stratasys, has released results from its new 3D Printing Trends Report, which includes over 1,200 responses from professionals across multiple industries, including aerospace, industrial goods, military and defense, medical and automotive. Key findings in the report reveal that nearly three-quarters (74%) of respondents are planning to invest in 3D printing technology in 2021, with 50% planning to spend up to $100,000. “These findings confirm what we have known for some time—and that is the potential of 3D printing to transform business operations,” says Nadav Goshen, CEO, MakerBot. “When faced with the kind of challenges that businesses…

Found in Robotics News & Content, with a score of 49.26

Stratasys Ltd. announces a new multi-year technical partnership agreement with Team Penske to continue to incorporate use of 3D printing on all Team Penske NASCAR, INDYCAR and IMSA SportsCar teams. “Stratasys has consistently contributed to our ability to reach new solutions for improving our race performance ahead of the competition,” says Team Penske President Tim Cindric. “Our 3D printing strategy has always been to produce high-quality parts for our racing operations in the shortest amount of time, and the ever-evolving additive technology from Stratasys gives us confidence in our approach.” Team Penske and Stratasys have worked together through five championships…